News Detail

Advanced Fixturing Techniques Using T-Slot Platforms

author:hxrtools Time:2026-01-06 14:54:23 Click:146

Advanced Fixturing Techniques Using T-Slot Platforms

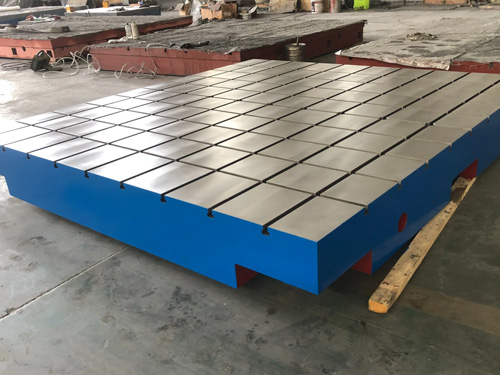

A T-slot Cast Iron Platform is a critical foundation for advanced fixturing systems used in modern machining and fabrication environments. As manufacturing moves toward higher precision, faster changeovers, and flexible production, the way workpieces are secured directly affects accuracy, repeatability, and productivity.

As a T-slot Cast Iron Platform manufacturer with stable production capability, supplying platforms for batch and industrial-scale applications requires a deep understanding of material behavior, structural design, and real-world machining demands. This article explores advanced fixturing techniques enabled by T-slot platforms and explains why they remain essential in professional production environments.

1. The Role of Fixturing in Precision Machining

Fixturing is more than simply holding a workpiece in place. Effective fixturing ensures positional accuracy, minimizes vibration, and maintains stability under cutting forces.

Inconsistent or poorly designed fixtures can lead to dimensional errors, surface defects, and reduced tool life. A rigid and adaptable base platform is therefore essential for achieving reliable machining results.

2. Why T-Slot Cast Iron Platforms Are Widely Used

2.1 Structural Rigidity and Load Capacity

Cast iron offers excellent stiffness and compressive strength, making it ideal for heavy-duty fixturing applications. A T-slot cast iron platform resists deformation even under high clamping forces and heavy workpiece loads.

This rigidity helps maintain alignment between the tool, fixture, and workpiece throughout the machining process.

2.2 Integrated Modularity

The T-slot design allows fixtures, clamps, and locating elements to be positioned freely across the platform surface. This modularity supports a wide range of part geometries and machining operations without requiring dedicated fixtures for every setup.

3. Advanced Fixturing Layout Strategies

3.1 Modular Fixture Systems

Using standardized clamps, stops, and locating pins within T-slots enables rapid fixture reconfiguration. Modular systems reduce setup time and improve flexibility in multi-part or small-batch production.

This approach is particularly effective in job shops and mixed-production environments.

3.2 Multi-Point Clamping for Stability

Advanced fixturing often relies on multi-point clamping strategies to distribute forces evenly. A T-slot cast iron platform provides the necessary anchor points to position clamps precisely where they are most effective.

Balanced clamping minimizes distortion and improves machining accuracy.

4. Vibration Control and Surface Quality

4.1 Natural Damping Properties of Cast Iron

One of the key advantages of cast iron is its inherent vibration damping capability. Compared to fabricated steel bases, cast iron platforms absorb and dissipate vibrational energy more effectively.

Reduced vibration leads to improved surface finish, tighter tolerances, and extended tool life.

4.2 Stability During Heavy Cutting

During aggressive milling or drilling operations, cutting forces fluctuate continuously. A heavy T-slot cast iron platform provides mass and damping that stabilize the entire setup, reducing chatter and unwanted movement.

5. Precision Alignment and Repeatability

5.1 Accurate Workpiece Positioning

The precision-machined surface of a T-slot platform serves as a reliable reference plane. When combined with locating elements, it enables repeatable positioning across multiple setups.

This repeatability is essential for multi-operation machining and high-volume production.

5.2 Supporting Automated Processes

In automated or semi-automated machining cells, consistent fixture positioning is critical. T-slot platforms support automation by allowing fixtures to be mounted and aligned with minimal adjustment.

6. Flexibility for Complex and Irregular Parts

Complex or irregularly shaped parts often require custom fixturing solutions. The open layout of T-slots allows fixtures to be arranged in non-standard configurations without compromising stability.

This flexibility reduces the need for custom base plates and shortens production lead times.

7. Manufacturing Quality and Production Consistency

The performance of a T-slot cast iron platform depends heavily on manufacturing quality. Controlled casting, proper stress relief, and precision machining ensure flatness, slot accuracy, and long-term stability.

Manufacturers with standardized production processes can supply platforms with consistent dimensions and performance across bulk orders, supporting scalable industrial applications.

8. Long-Term Durability and Maintenance

Cast iron platforms are known for their durability and resistance to wear. The T-slots maintain dimensional accuracy over long service periods, even with frequent fixture changes.

Routine cleaning and inspection help preserve surface quality and ensure reliable clamping performance.

Conclusion: Maximizing Fixturing Performance with T-Slot Cast Iron Platforms

Advanced fixturing techniques rely on a stable, flexible, and durable foundation. A T-slot Cast Iron Platform delivers the rigidity, modularity, and vibration control required for precision machining across a wide range of applications.

For organizations sourcing platforms from a manufacturer with reliable production capacity and bulk supply capability, investing in high-quality T-slot cast iron platforms ensures consistent fixturing performance, reduced setup times, and improved machining accuracy. In modern production environments, the right platform is not just a base—it is a strategic tool for manufacturing efficiency.

References

GB/T 7714:Nee A Y C, Whybrew K. Advanced fixture design for FMS[M]. Springer Science & Business Media, 2012.

MLA:Nee, Andrew Yeh Chris, and Kenneth Whybrew. Advanced fixture design for FMS. Springer Science & Business Media, 2012.

APA:Nee, A. Y. C., & Whybrew, K. (2012). Advanced fixture design for FMS. Springer Science & Business Media.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province