News Detail

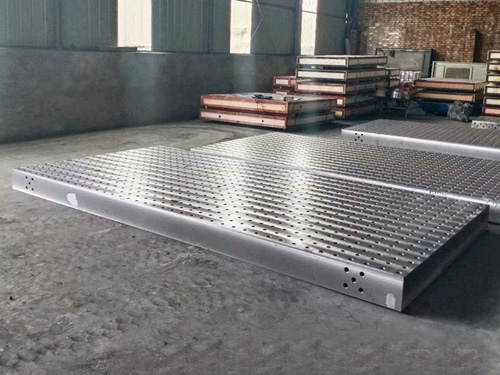

Advanced Welding Platforms for Aviation Technology Applications

author:hxrtools Time:2026-01-12 15:24:07 Click:174

Aviation Technology Welding Tool Platforms as a Manufacturing Backbone

In the aerospace industry, where precision tolerances are measured in microns and structural integrity is non-negotiable, every piece of equipment plays a critical role. Among these, the aviation technology welding tool platform stands out as a foundational element that supports advanced welding operations across aircraft structures, engine components, and aerospace assemblies.

Unlike general-purpose welding tables, aviation-specific welding platforms are engineered to meet extreme demands for accuracy, thermal stability, and repeatability. Designed and manufactured by specialized manufacturers with advanced production capabilities, these platforms support both manual and automated welding systems used throughout modern aerospace facilities.

Why Aviation Welding Requires Advanced Tool Platforms

Aerospace welding involves lightweight alloys, complex geometries, and strict quality regulations. Aluminum alloys, titanium components, and high-strength steels must be welded with absolute consistency to ensure flight safety and long-term durability.

An advanced aviation technology welding tool platform provides a rigid, distortion-resistant base that ensures components remain perfectly aligned throughout the welding cycle. Without such a platform, even the most skilled welding process risks dimensional deviation, structural stress, or premature fatigue.

Precision Engineering at the Core of Aviation Welding Platforms

Ultra-Flat and Stable Surfaces

Advanced welding platforms for aviation applications are precision-machined to deliver exceptional flatness and rigidity. This level of surface accuracy ensures that aircraft components are positioned correctly before, during, and after welding.

The stability of the platform minimizes vibration and thermal deformation, which is especially critical when working with thin-walled aerospace components.

Modular Fixturing for Complex Aerospace Parts

Aviation assemblies often involve irregular shapes and multi-axis positioning. Modern aviation technology welding tool platforms integrate modular hole patterns, clamping grids, and adjustable fixtures that allow rapid configuration for different aircraft components.

This flexibility improves setup efficiency while maintaining the strict positioning accuracy required in aerospace welding.

Supporting Automated and Robotic Welding Systems

As aerospace manufacturers increasingly adopt robotic and automated welding technologies, the welding platform must integrate seamlessly with these systems.

Advanced platforms are designed to:

·Support robotic arm access from multiple angles

·Maintain positional repeatability for programmed weld paths

·Integrate with sensors, grounding systems, and alignment devices

A professionally designed aviation technology welding tool platform ensures that automation investments deliver consistent and repeatable results across high-volume production environments.

Material Selection for Aerospace Welding Platforms

The choice of material directly affects performance and lifespan. Aviation welding platforms are typically manufactured using:

·High-grade steel for strength and load capacity

·Cast iron for vibration damping and thermal stability

·Surface-treated alloys for enhanced corrosion and spatter resistance

Reliable manufacturers employ controlled production processes such as CNC machining, stress relief treatment, and precision surface grinding to ensure long-term dimensional stability.

Safety and Compliance in Aviation Welding Environments

Safety is paramount in aerospace manufacturing. Advanced welding platforms contribute to a safer working environment by:

·Securely holding components to prevent movement

·Supporting proper electrical grounding during welding

·Reducing operator exposure to unstable or misaligned assemblies

These features help manufacturers meet stringent aviation industry standards and quality certifications.

Efficiency Gains Through Platform Optimization

An optimized aviation technology welding tool platform directly impacts production efficiency by:

·Reducing setup and changeover time

·Minimizing rework caused by misalignment

·Supporting repeatable, high-accuracy welding operations

In large-scale aerospace facilities, these improvements translate into measurable cost savings and improved production throughput.

Selecting the Right Aviation Welding Tool Platform

When evaluating welding platforms for aviation applications, manufacturers should consider:

Load Capacity and Structural Rigidity

The platform must support heavy aerospace components without deflection.

Customization Capability

Aviation projects often require customized hole patterns, fixtures, and dimensions.

Scalable Production and Supply

Working with a capable manufacturer that offers bulk production ensures consistent quality and timely delivery for long-term projects.

Long-Term Reliability

Platforms should maintain accuracy over years of continuous use in demanding industrial environments.

The Strategic Value of Manufacturer-Level Production

Partnering directly with a professional manufacturer specializing in aviation technology welding tool platforms offers key advantages:

·Consistent quality control across large production volumes

·Engineering support for customized aerospace applications

·Cost efficiency through direct factory supply

·Reliable delivery schedules for bulk orders

These benefits are especially important for aerospace manufacturers operating under tight timelines and regulatory requirements.

Conclusion: A Foundation for Aerospace Manufacturing Excellence

In aviation manufacturing, welding accuracy is inseparable from safety, performance, and compliance. An advanced aviation technology welding tool platform provides the structural foundation needed to achieve these standards consistently.

Designed by experienced manufacturers with robust production capabilities, these platforms support precision welding, automation integration, and long-term operational efficiency. For aerospace companies seeking to enhance weld quality, reduce errors, and scale production, investing in the right welding platform is not merely an option—it is a strategic necessity.

References

GB/T 7714:Goldak J, Chakravarti A, Bibby M. A new finite element model for welding heat sources[J]. Metallurgical transactions B, 1984, 15(2): 299-305.

MLA:Goldak, John, Aditya Chakravarti, and Malcolm Bibby. "A new finite element model for welding heat sources." Metallurgical transactions B 15.2 (1984): 299-305.

APA:Goldak, J., Chakravarti, A., & Bibby, M. (1984). A new finite element model for welding heat sources. Metallurgical transactions B, 15(2), 299-305.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province