News Detail

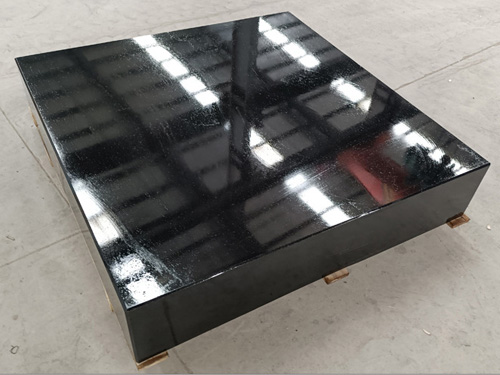

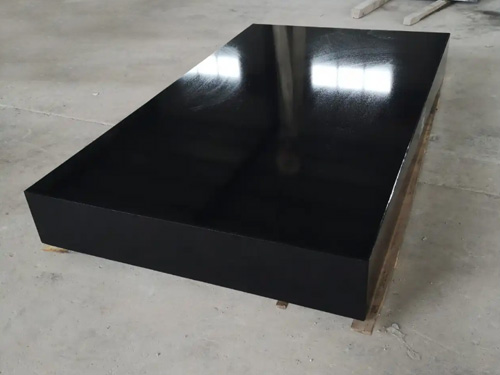

Benefits of Granite Platforms in Precision Engineering

author:hxrtools Time:2025-09-20 12:57:20 Click:69

The Granite Advantage

In precision engineering, the search for absolute accuracy never stops. Behind every advanced measuring instrument or automated inspection unit is a Granite Platform—a foundation built for stability, reliability, and long-term accuracy.

Granite’s physical properties make it uniquely suited for precision tasks, from metrology labs to robotic inspection lines. Many businesses secure their equipment from a Chinese manufacturer with the capacity for bulk supply, ensuring both quality and cost-effectiveness at scale.

Why Granite Excels in Precision Applications

1. Consistent Dimensional Integrity

Granite resists deformation even when exposed to heavy loads or environmental changes. This natural stability ensures the surface maintains its original flatness across years of use.

2. Resistance to Temperature Shifts

Where metals expand and contract with heat, granite remains virtually unaffected. Its low coefficient of thermal expansion makes it an excellent choice for environments that demand thermal consistency.

3. Natural Vibration Damping

Precision instruments can be thrown off by the slightest vibration. Granite’s crystalline structure absorbs and neutralizes disturbances, protecting sensitive inspection and measuring systems.

4. Longevity Without Corrosion

Unlike steel or iron platforms, granite does not rust or corrode, even in damp or chemically exposed settings. This characteristic reduces maintenance requirements and extends operational life.

5. Heavy-Duty Support

A granite platform is capable of carrying substantial weight without distortion, making it indispensable for large-scale inspection setups or automated systems involving heavy components.

Key Uses of Granite Platforms

·Inspection and Metrology – Serving as the reference base for coordinate measuring machines (CMMs), calibration devices, and precision gauges.

·Laboratory Work – Providing stable, non-reactive surfaces for research and testing environments.

·Automation and Robotics – Offering a reliable foundation for robotic systems that demand accurate alignment.

·Quality Control in Manufacturing – Ensuring consistent product verification against tight tolerances.

Maintaining Granite Platforms for Longevity

Granite is durable, but attention to care ensures it performs flawlessly:

·Keep It Clean – Regularly remove particles, oils, and residues.

·Prevent Surface Damage – Avoid impacts from tools or components.

·Check Flatness Periodically – Precision instruments should confirm surface stability over time.

·Control the Environment – Store and use platforms in dry, stable areas to prevent unnecessary wear.

Granite Compared to Other Platform Materials

Although metals like cast iron and steel are sometimes used, granite brings unique advantages:

·Superior thermal stability compared to metals.

·No corrosion issues, reducing upkeep costs.

·Greater vibration control, vital for delicate measuring devices.

·Minimal maintenance needs, ensuring reliability in high-demand environments.

For these reasons, granite continues to be the preferred option for high-accuracy engineering worldwide.

Partnering with the Right Supplier

Securing the right platform means more than just choosing the right material. Partnering with a dependable China supplier who can provide bulk supply guarantees consistency in material sourcing, precise machining, and efficient delivery. For companies scaling their automation and metrology systems, this is a decisive factor in long-term success.

Conclusion

The Granite Platform plays an irreplaceable role in precision engineering. With unmatched thermal stability, vibration control, and durability, it delivers the foundation needed for metrology, robotics, and automation.

By maintaining platforms carefully and sourcing from experienced Chinese manufacturers that offer bulk supply, industries gain a reliable and cost-effective solution. In precision-driven fields, the granite platform is not simply a tool—it is the cornerstone of accuracy and consistency.

References

GB/T 7714:Wang J, Zhang B, Xue B. Computer-controlled lapping system for granite surface plates[J]. Journal of Manufacturing Systems, 2000, 19(3): 149-155.

MLA:Wang, Jiexin, Bi Zhang, and Binyuan Xue. "Computer-controlled lapping system for granite surface plates." Journal of Manufacturing Systems 19.3 (2000): 149-155.

APA:Wang, J., Zhang, B., & Xue, B. (2000). Computer-controlled lapping system for granite surface plates. Journal of Manufacturing Systems, 19(3), 149-155.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province