News Detail

Best T-Slot Platform Configurations for Industrial Machinery

author:hxrtools Time:2025-09-11 11:17:08 Click:157

Why Platform Design Matters

In industrial production, every detail affects output. Machines and measuring tools can only perform well if they are built on a stable base. One of the most effective solutions is the T-slot cast iron platform—a heavy-duty foundation that combines strength, versatility, and long-term accuracy. Selecting the right design helps factories achieve consistent performance while reducing maintenance costs.

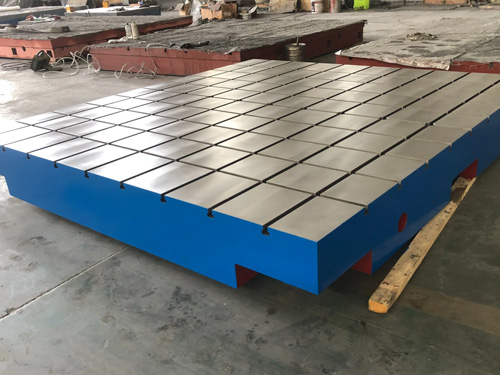

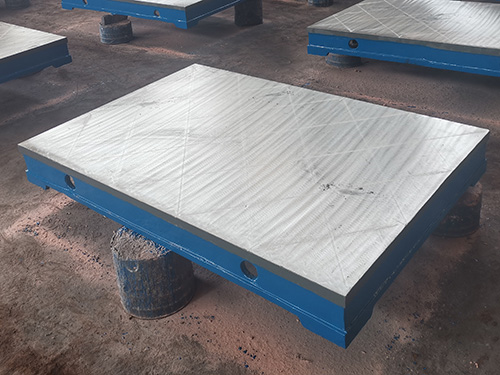

Defining the T-Slot Cast Iron Platform

A T-slot platform is a cast iron surface engineered with grooves (T-shaped slots). These grooves make it easy to clamp fixtures, align parts, and support machining processes. Typical applications include:

·Machining Support – Holding workpieces firmly for cutting, drilling, or milling.

·Inspection Base – Acting as a flat and reliable reference plane.

·Assembly Work – Providing load-bearing stability for fitting and testing.

Thanks to its flatness, toughness, and vibration resistance, the T-slot cast iron platform is considered a cornerstone of precision manufacturing.

Core Advantages

1.Strong Load Endurance – Withstands heavy-duty equipment without bending.

2.Precision Surface – Maintains accuracy for dimensional inspection and machining.

3.Quick Setup Options – T-slots accept different clamps and fixtures for flexible layouts.

4.Durability – Cast iron material performs well under continuous operation.

Top Configurations for Industrial Use

Factories can choose from several platform types depending on workflow:

Single-Surface T-Slot Platform

Simple and efficient, designed for workshops that need a compact clamping solution.

Double-Surface T-Slot Platform

Two usable sides, often used to speed up operations by reducing setup changeovers.

Modular Systems

Built in sections that lock together, these are ideal when scaling production lines or rearranging workshop layouts.

Heavy-Duty Reinforced Platforms

Ribbed or strengthened from below, making them suitable for aerospace, automotive, or shipbuilding applications where loads are extreme.

Custom-Made Platforms

Adapted with non-standard spacing, threaded inserts, or additional machining to meet specialized needs.

How to Choose the Right Platform

Before committing to a purchase, key factors to evaluate include:

·Overall Size & Thickness – Must fit your machine dimensions and loading requirements.

·Flatness Standard – Higher grades are crucial for precision measurement tasks.

·Slot Profile – Should match the bolts and clamps in your facility.

·Surface Coating – Protective finishes extend platform life.

·Supplier Credibility – A reliable China supplier with proven bulk supply capacity ensures stable deliveries.

Why Source from Chinese Manufacturers?

China has developed into one of the largest producers of cast iron tooling platforms. Partnering with a Chinese manufacturer offers clear advantages:

·Verified Bulk Supply – Factories can handle large-scale orders, showing they are genuine producers, not just resellers.

·Lower Costs – Direct factory pricing cuts overhead.

·Tailored Services – Many suppliers machine platforms to specific dimensions and tolerances.

·Global Logistics – Export-ready packaging ensures safe international shipping.

This makes Chinese suppliers a practical choice for both small workshops and global enterprises.

Care and Maintenance Tips

To extend service life and maintain performance:

·Clean Regularly – Remove oil, dust, and chips from slots.

·Protect Against Rust – Apply a light coating of protective oil during storage.

·Inspect for Flatness – Check periodically to confirm tolerances are within range.

·Store Properly – Keep in a dry, stable environment when not in use.

Final Thoughts

The T-slot cast iron platform remains the backbone of many industrial operations. Whether used for machining, assembly, or inspection, its reliability and flexibility make it indispensable. Selecting the best configuration—single, double, modular, reinforced, or custom—can transform workflow efficiency.

Working with a trusted Chinese manufacturer that can provide bulk supply ensures not only consistent quality but also cost-effective sourcing. For any factory aiming at long-term accuracy and stability, the right T-slot platform is more than equipment—it’s an investment in sustainable productivity.

References

GB/T 7714:Neugebauer R, Denkena B, Wegener K. Mechatronic systems for machine tools[J]. CIRP annals, 2007, 56(2): 657-686.

MLA:Neugebauer, Reimund, B. Denkena, and Konrad Wegener. "Mechatronic systems for machine tools." CIRP annals 56.2 (2007): 657-686.

APA:Neugebauer, R., Denkena, B., & Wegener, K. (2007). Mechatronic systems for machine tools. CIRP annals, 56(2), 657-686.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province