News Detail

Best Welding Table Options for Small Workshops

author:hxrtools Time:2025-11-15 10:33:25 Click:51

No matter how compact your workspace may be, every welder knows that a sturdy welding table is the foundation of precision and efficiency. It’s where creativity meets structure, ensuring every joint, bead, and angle comes together flawlessly. For small workshops, selecting the right table design can make all the difference — maximizing space while improving overall productivity.

Today, more welders are turning to China manufacturers that provide bulk supply of high-quality welding tables, offering the perfect mix of affordability, reliability, and customization to fit diverse fabrication needs.

1. The Importance of a Proper Welding Table

A welding table is more than just a surface to work on. It’s a carefully engineered piece of equipment designed to withstand heat, pressure, and heavy-duty usage. A flat, stable platform ensures clean welds, proper alignment, and a safe working environment.

A well-built table also improves workflow efficiency by providing easy access for clamping, measuring, and repositioning parts. For small workshops where every inch of space matters, a good welding table is not just a tool — it’s the heart of production.

2. Essential Features of Quality Welding Tables

To perform consistently in a compact workspace, your welding table should combine durability, adjustability, and flexibility. Some must-have characteristics include:

·High Precision Flatness: Guarantees consistent weld geometry.

·Sturdy Construction: Typically made from heat-treated steel or cast iron to resist warping.

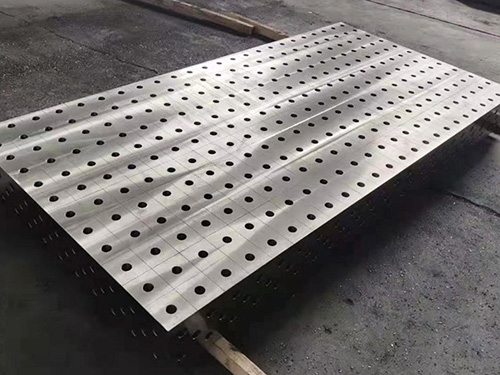

·Perforated or Slotted Surface: Enables flexible clamping and fixture positioning.

·Height Adjustment Options: Promotes ergonomic posture and reduces fatigue.

·Anti-Corrosion Coating: Protects the surface from oxidation and extends service life.

These design factors directly impact both productivity and weld quality, especially in workshops with frequent project changes.

3. Space-Efficient Welding Table Designs

Small workshops benefit most from flexible and compact table systems. Below are popular designs that combine space efficiency with practical functionality.

a. Foldable Welding Tables

Foldable models are ideal for temporary or portable setups. They can be stored easily when not in use and still support light-to-medium welding loads. These tables are perfect for hobbyists or technicians with mobile operations.

b. Modular Welding Tables

A modular welding table offers unmatched versatility. By connecting or detaching individual panels, operators can adjust the work area for different components. It’s a scalable solution for small workshops handling multiple part sizes.

c. Adjustable Height Tables

Adjustable-height tables improve ergonomics and safety. Welders can modify the height for sitting or standing positions, reducing back strain and improving welding precision during long sessions.

d. Multi-Purpose Tables

Some designs integrate tool storage drawers, grinding zones, or vise mounts, transforming one surface into a multi-functional workstation. This approach saves both time and valuable space.

4. Material Choices and Surface Finishing

The choice of material defines the strength and heat resistance of your welding table:

·Mild Steel: A cost-effective option for standard welding tasks.

·Cast Iron: Offers excellent vibration damping and flatness retention, making it ideal for precise alignment.

·Aluminum Alloy: Lightweight and corrosion-resistant, perfect for smaller or mobile setups.

Many China suppliers specialize in producing tables with advanced surface finishes such as black oxide or anti-spatter coatings. Working directly with a China manufacturer that provides bulk supply ensures cost savings, steady availability, and consistent surface quality across multiple units.

5. Why Choose a China Manufacturer

China has become a global hub for welding table production thanks to its advanced CNC machining and large-scale manufacturing capacity. Partnering with a China manufacturer offers distinct benefits:

·Reliable Bulk Supply: Factories maintain stable production cycles and deliver consistent batches suitable for industrial use.

·Competitive Pricing: Direct factory sourcing minimizes distribution costs while maintaining high precision.

·Customizable Options: From table size to hole spacing and finish, customization is widely supported.

·Quality Certifications: ISO-compliant and CE-certified factories guarantee performance and durability.

These advantages make China an attractive source for workshops seeking dependable, cost-efficient solutions.

6. Maintenance and Longevity Tips

A high-quality welding table can serve you for years if properly maintained. Follow these steps to extend its lifespan:

1.Clean Regularly: Remove welding spatter, dust, and debris after each session.

2.Apply Protective Coating: Prevent rust and corrosion using anti-rust oil or sprays.

3.Check Alignment: Periodically inspect surface flatness and leg stability.

4.Avoid Heat Concentration: Spread welding operations evenly to prevent warping.

5.Store Indoors: Keep your table in a dry, shaded environment when not in use.

Proper maintenance not only preserves your equipment but also ensures continued welding precision.

7. Choosing the Right Table for Your Needs

When selecting a welding table for a small workshop, evaluate:

·Workload Requirements: Match the table’s load rating to your heaviest projects.

·Space Layout: Choose foldable or modular tables to maximize workspace efficiency.

·Frequency of Use: Heavier cast-iron tables suit daily fabrication; lighter steel ones work for intermittent jobs.

·Supplier Reliability: Look for a China supplier with experience in bulk production and export capability.

The right combination of design and supplier ensures smooth workflow, precision results, and long-term value.

Conclusion: Welding Tables as the Core of Compact Workshops

Every successful welder understands the importance of a stable and precise welding table. For small workshops, investing in a high-quality, space-saving design boosts productivity, enhances accuracy, and ensures safety.

By sourcing professional welding tables from an experienced China manufacturer with bulk supply capabilities, workshop owners can enjoy industrial-grade performance without the heavy price tag.

A welding table isn’t merely an accessory—it’s the core foundation that transforms limited space into a powerful, efficient, and professional fabrication area.

References

GB/T 7714:Hajduk M, Semjon J, Vagaš M. Design of the welding fixture for the robotic stations for spot welding based on the modular concept[J]. Acta Mechanica Slovaca, 2009, 13(3): 30-37.

MLA:Hajduk, Mikuláš, Ján Semjon, and Marek Vagaš. "Design of the welding fixture for the robotic stations for spot welding based on the modular concept." Acta Mechanica Slovaca 13.3 (2009): 30-37.

APA:Hajduk, M., Semjon, J., & Vagaš, M. (2009). Design of the welding fixture for the robotic stations for spot welding based on the modular concept. Acta Mechanica Slovaca, 13(3), 30-37.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province