News Detail

Common Mistakes to Avoid When Installing T-Slot Platforms

author:hxrtools Time:2025-12-06 15:54:28 Click:114

The Importance of Proper Installation

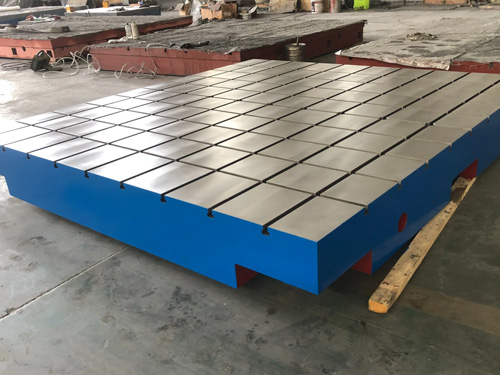

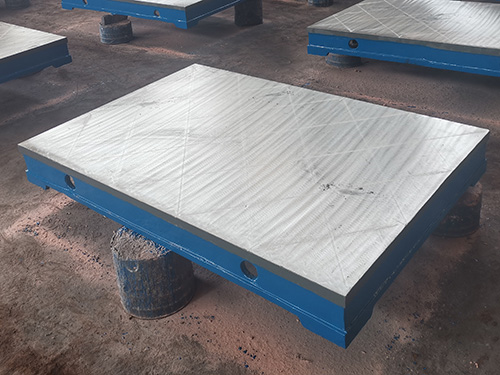

A T-slot Cast Iron Platform serves as the backbone for a wide range of precision activities—from equipment alignment to heavy component assembly. Because these platforms are engineered to deliver high rigidity and dimensional stability, their installation process must be carried out with great care. Even minor oversights can introduce inaccuracies that affect machining quality, measurement results, or long-term operational reliability.

For workshops, laboratories, and facilities that operate high-volume Production lines or function as a specialized Manufacturer, understanding common installation pitfalls is essential. Avoiding the mistakes below will help ensure the platform performs as intended.

1. Installing the Platform on an Unprepared Base

Many installation issues begin with the foundation itself. A T-slot platform may look solid, but placing it on an uneven, unstable, or weak base can cause:

·Undesirable deflection

·Gradual twisting of the cast iron plate

·Poor vibration resistance

·Difficulty securing fixtures accurately

What to do instead:

Prepare the foundation carefully. It should be fully cured, leveled to a high tolerance, and structurally strong enough to support the platform’s weight without shifting.

2. Relying on Basic Tools for Leveling

Precision equipment requires precision tools. One common mistake is leveling the platform using only general workshop levels, which lack the accuracy needed for establishing a true reference plane.

This can lead to:

·Measurement discrepancies

·Inconsistent clamping pressure

·Reduced machining accuracy

Better approach:

Use a certified precision level, leveling wedges, or a laser alignment system to bring the platform into an even and stable plane.

3. Excessive Tightening of Anchors or Fasteners

T-slot Cast Iron Platforms are not meant to be “forced” into position. Over-tightening the anchor bolts or mounting hardware can lead to subtle deformations that compromise accuracy.

This mistake commonly causes:

·Internal casting stress

·Micro bending

·Long-term instability

Recommendation:

Apply even pressure, tighten gradually, and follow the platform’s recommended torque guidelines.

4. Overlooking Environmental Factors

Environmental conditions play a major role in platform stability. Although cast iron has excellent thermal inertia, extreme or fluctuating conditions can still affect performance.

Avoid installation in areas with:

·Significant temperature swings

·Constant vibration from heavy machinery

·Direct exposure to chemicals or humidity

·Unstable flooring structures

Tip:

Choose a controlled environment when possible, or incorporate vibration isolation pads if the surrounding area has unavoidable movement.

5. Incorrect Placement of Support Points

Support points exist for a reason: to evenly distribute the platform’s load. Placing supports in arbitrary locations is one of the quickest ways to distort a T-slot Cast Iron Platform.

Consequences include:

·Bowed or twisted surfaces

·Localized stress concentrations

·Reduced precision during assembly tasks

To avoid this:

Follow the manufacturer’s support layout. Larger platforms require specific support spacing to maintain the plate’s geometric accuracy.

6. Using the Wrong T-Slot Accessories

Incompatible fasteners, low-quality T-nuts, or mismatched clamping components can damage the T-slots or reduce the stability of fixtures during operation.

Typical issues:

·Slot wall scarring

·Bolt slippage

·Uneven clamping pressure

Correct practice:

Select accessories designed specifically for the platform’s T-slot profile, with adequate hardness and load ratings.

7. Forgetting About Post-Installation Maintenance

A newly installed T-slot Cast Iron Platform is not maintenance-free. Long-term neglect will inevitably impact its flatness and operational reliability.

Neglect often leads to:

·Corrosion on the surface

·Buildup of dust or metallic debris

·Subtle flatness deviations

Simple maintenance routine:

·Keep the surface clean

·Apply a protective oil layer regularly

·Check mounting stability yearly

·Inspect for rust spots or dings

8. Not Training Operators on Proper Usage

Even a perfectly positioned platform can be compromised by untrained personnel. Operators who don’t understand load balance or proper clamping techniques may unintentionally damage the platform.

Common operator errors include:

·Dropping tools or parts on the surface

·Applying excessive force on one section

·Using inappropriate fixture systems

Solution:

Provide clear training on safe handling, correct clamping methods, and surface care.

9. Poor Handling During Transportation or Placement

Cast iron is strong but brittle at the edges. Rough handling—especially during lifting or moving—can result in chips, edge cracks, or alignment inaccuracies.

Preventive measure:

Use soft slings, lifting eyes, or a certified hoisting system. Never drag the platform or allow contact with sharp metal edges.

10. Ignoring Manufacturer Installation Guidelines

Every T-slot Cast Iron Platform Manufacturer includes installation instructions tailored to the platform’s grade, size, and intended application. Skipping these guidelines often results in improper support, uneven leveling, or voided warranty conditions.

Be sure to review:

·Support point diagrams

·Allowable load specifications

·Recommended leveling methods

·Environmental considerations

Conclusion

Installing a T-slot Cast Iron Platform correctly is crucial for maintaining a stable and precise working surface. From foundation preparation to operator training, each step influences the platform’s long-term accuracy and durability. For facilities involved in precision engineering, high-volume Production, or operating as a specialized Manufacturer, avoiding these common mistakes ensures maximum performance and protects your investment.

A well-installed T-slot platform is more than just a piece of cast iron—it is the foundation for precise, reliable, and repeatable work that supports the entire workflow of your facility.

References

GB/T 7714:Jcgm J. Evaluation of measurement data—Guide to the expression of uncertainty in measurement[J]. Int. Organ. Stand. Geneva I等N, 2008, 50: 134.

MLA:Jcgm, J. C. G. M. "Evaluation of measurement data—Guide to the expression of uncertainty in measurement." Int. Organ. Stand. Geneva I等N 50 (2008): 134.

APA:Jcgm, J. C. G. M. (2008). Evaluation of measurement data—Guide to the expression of uncertainty in measurement. Int. Organ. Stand. Geneva I等N, 50, 134.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province