News Detail

Welding Table Care During Extended Downtime: Essential Pre‑Use Checks

author:hxrtools Time:2025-08-16 17:01:04 Click:92

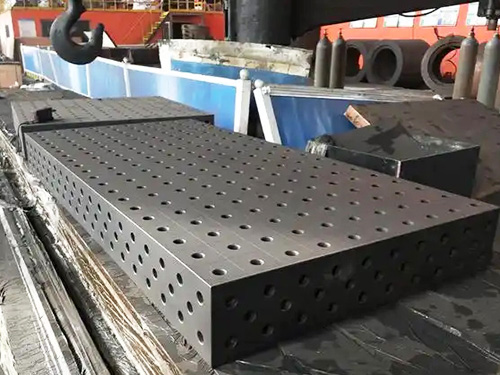

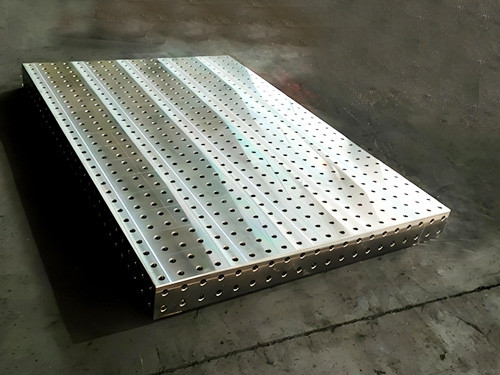

A welding table is the backbone of precise fabrication. When it sits unused for weeks or months—whether because of seasonal slowdown, a workshop move, or personal leave—its surface and components can suffer. Dust, oxidation, hidden rust, or slight misalignment may develop quietly over time.

To avoid performance loss, it’s important to safeguard the table during storage and examine it thoroughly before it goes back into service. This article explains how to store a welding table correctly and outlines a step‑by‑step inspection routine for safe reactivation.

1. What Happens When a Welding Table Is Left Idle

Prolonged inactivity exposes the welding table to a few common risks:

1.Surface Rust

Humidity in the air can lead to small rust patches or discoloration, even in indoor environments.

2.Hidden Corrosion in Mounting Points

Moisture and debris trapped in fixture holes and clamping areas may trigger internal corrosion.

3.Loss of Precision

Seasonal temperature swings can cause minimal but important shifts in flatness, affecting welding accuracy.

4.Dust and Contaminants

Layers of dust, fine metal particles, and even pests may collect on the work surface or in drawers.

2. Preparing a Welding Table for Storage

If your welding table won’t be used for an extended time, take these preventive steps:

a. Clean Thoroughly

·Remove welding residue, slag, and shavings.

·Wipe with a dry microfiber cloth; avoid wet cleaning methods.

b. Apply a Moisture Barrier

·Coat the top and any fixture points with rust‑preventive oil or spray.

·In humid regions, a wax‑based coating offers stronger protection.

c. Use a Breathable Cover

·Shield the table from dust using a cloth that allows air circulation.

·Avoid airtight plastic covers that trap condensation.

d. Control the Storage Environment

·Keep the table in a dry, well‑ventilated location.

·A dehumidifier is helpful for high‑moisture workshops.

3. Inspection Steps Before Reactivating the Welding Table

Before putting the table back into service, inspect these key areas:

a. Surface Check

·Scan for rust, pitting, or uneven coloration.

·Remove any rust with a wire brush or abrasive pad and re‑oil.

b. Verify Flatness

·Test with a straightedge or level to detect warping.

·Correct issues before precision welding.

c. Inspect Fixture Holes and Clamps

·Remove any debris or oxidation inside holes.

·Lightly oil for smooth clamping performance.

d. Examine Drawers and Moving Parts

·Test for smooth sliding and lubricate rails if needed.

·Clear away dust or grit.

e. Confirm Structural Stability

·Check weld joints, legs, and bracing for looseness.

·Tighten or repair as necessary.

4. Bringing the Welding Table Back Into Use

After inspection, prepare the table for active work:

1.Clean Off Storage Coating

Remove any heavy oil or wax used during storage. Apply a fresh, thin layer of light machine oil.

2.Check Fixture Compatibility

Ensure clamps and jigs fit and operate correctly.

3.Test Weld

Run a short welding job to confirm grounding and surface integrity.

4.Resume Maintenance Schedule

Reinstate your normal cleaning and oiling routine.

5. Avoiding Future Downtime Problems

To prevent future storage‑related damage:

·Apply Rust Inhibitors Regularly – Even during short breaks.

·Keep Humidity Low – Use a hygrometer to track moisture levels.

·Avoid Loading the Table – Heavy storage items can distort the surface.

·Periodic Checks – Inspect every few months, even in storage.

Conclusion

With the right care, a welding table can remain accurate and rust‑free for decades. Long storage doesn’t have to cause permanent damage—if you protect it from moisture, cover it correctly, and check it before use.

Following these guidelines will help you avoid costly repairs, keep your welding table ready for precision work, and ensure it remains a reliable part of your workshop for years to come.

References

GB/T 7714:Goto H, Buckley D H. Effect of humidity on fretting wear of several pure metals[R]. 1984.

MLA:Goto, Hozumi, and Donald H. Buckley. Effect of humidity on fretting wear of several pure metals. No. NAS 1.60: 2403. 1984.

APA:Goto, H., & Buckley, D. H. (1984). Effect of humidity on fretting wear of several pure metals (No. NAS 1.60: 2403).

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province