News Detail

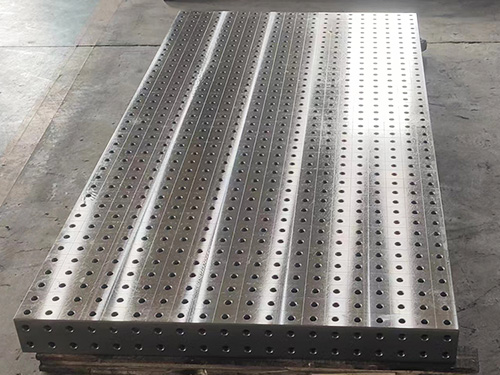

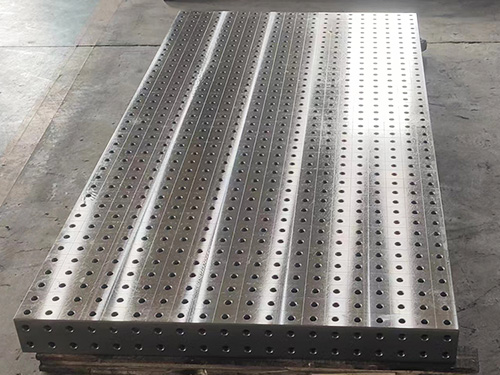

Beginner’s Complete Welding Table Setup Guide for 2025

author:hxrtools Time:2025-08-22 14:32:02 Click:134

If you’re beginning your welding journey, one piece of equipment will define your workflow: the welding table. Far from being a simple workbench, this essential fixture serves as the foundation for precision fabrication, safety, and efficiency. In this comprehensive guide, we’ll explain why every workshop needs a welding table, how to choose the right one, and the proper steps for setting it up in 2025.

Why Every Workshop Needs a Welding Table

A dedicated welding table is a cornerstone of any serious metal fabrication environment. Unlike standard benches, welding tables are purpose-built to withstand intense heat, heavy loads, and repetitive clamping without warping or degrading. Their flat, robust surface ensures dimensional accuracy and stable positioning—critical factors for producing quality welds.

Core Benefits of a Welding Table

·Durability: Designed to resist thermal distortion and surface damage from sparks and spatter.

·Safety: Non-flammable, grounded surfaces minimize electrical and fire hazards.

·Workflow Efficiency: Integrated grid holes or T-slots allow for rapid clamping and flexible fixturing at multiple angles.

How to Select the Ideal Welding Table

Choosing the right welding table is about balancing your operational needs with space and budget considerations. Key factors include:

·Material Composition:

Opt for steel or cast iron construction for superior rigidity and thermal resistance. Steel tables are more cost-effective, while cast iron provides unmatched flatness and vibration damping.

·Surface Dimensions:

Match table size to your shop layout and project scale. For small workshops, compact modular tables with expansion options offer flexibility.

·Fixturing System:

Advanced tables feature precision-machined holes or T-slots, enabling quick, repeatable setups and complex joint positioning.

·Mobility & Stability:

In modular or confined workspaces, select tables with heavy-duty casters and locking mechanisms for stability during welding.

Step-by-Step Welding Table Setup in 2025

Step 1: Select an Optimal Location

Choose a well-ventilated area with adequate lighting. Welding produces fumes that can be harmful without proper air circulation. Bright, uniform illumination improves accuracy and reduces operator fatigue.

Step 2: Verify Flatness and Level

A level working surface is non-negotiable for precision welding. Use a high-accuracy machinist’s level to confirm flatness. Adjust table legs or employ precision shims until deviations are within acceptable tolerances (typically ±0.1 mm for professional setups).

Step 3: Install Fixturing and Clamping Tools

Secure positioning is key to consistent weld quality. Equip the table with:

·T-slot or modular clamps for structural rigidity

·Magnetic squares for quick alignment

·Toggle clamps for rapid part changes

Organize tools ergonomically for streamlined workflows.

Step 4: Implement Grounding and Safety Protocols

Proper grounding ensures current flow stability and minimizes shock hazards. Keep fire suppression equipment within reach and clear all combustible materials before initiating welds.

Maintenance for Long-Term Performance

Regular upkeep maximizes both performance and lifespan:

·Daily Cleaning: Remove slag, spatter, and debris after every session.

·Corrosion Control: Apply a thin coat of anti-rust oil or corrosion inhibitor to exposed surfaces.

·Periodic Inspection: Check structural joints, clamps, and leg assemblies for wear or misalignment. Replace compromised components promptly.

Common Setup Errors to Avoid

·Ignoring Leveling: Even slight surface irregularities compromise joint integrity.

·Improper Grounding: Increases risk of electrical hazards and inconsistent weld quality.

·Exceeding Load Capacity: Overloading can lead to permanent warpage or table failure.

Final Thoughts: The Foundation of Precision Welding

A welding table is not merely a flat platform—it’s an engineering tool that underpins accuracy, safety, and productivity in metal fabrication. By selecting the right model, implementing a professional setup, and following a disciplined maintenance routine, you position yourself for consistent, high-quality welds throughout 2025 and beyond.

Invest wisely—because in welding, your table defines your craft.

References

GB/T 7714:Suryanto A E, Lumbantobing M A, Murwantini S, et al. Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision[J]. G-Tech: Jurnal Teknologi Terapan, 2025, 9(1): 29-39.

MLA:Suryanto, Ahmad Eko, et al. "Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision." G-Tech: Jurnal Teknologi Terapan 9.1 (2025): 29-39.

APA:Suryanto, A. E., Lumbantobing, M. A., Murwantini, S., Samudra, A., & Supriyadi, S. (2025). Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision. G-Tech: Jurnal Teknologi Terapan, 9(1), 29-39.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province