News Detail

Understanding Cast Iron Platform Flatness: Key to Precision Machining

author:hxrtools Time:2025-08-25 15:24:34 Click:117

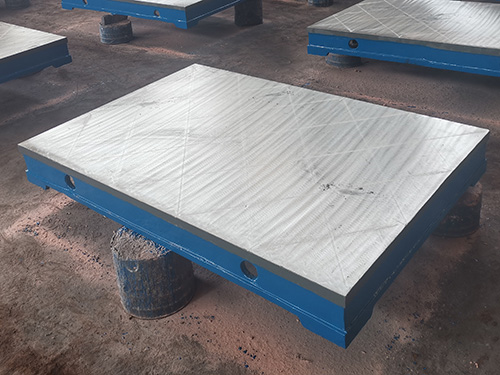

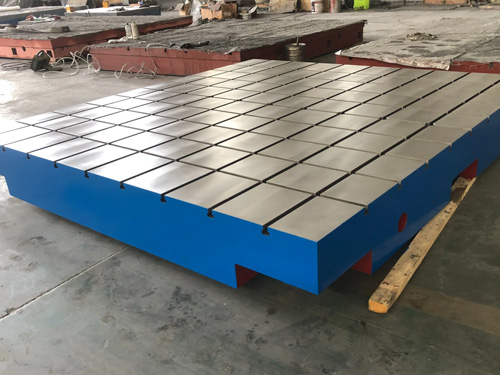

The Role of a Cast Iron Platform in Accurate Machining

For precision machining, the foundation of reliable measurements and component alignment is the cast iron platform. Far more than a simple bench, it provides a stable, rigid base critical for high-accuracy operations. Among the platform’s attributes, flatness is the single most important factor influencing performance. Even minor deviations in surface uniformity can cause measurement errors, misalignments, and compromised product quality. This guide examines why flatness matters, how to assess it, and best practices for maintaining it.

Defining Flatness on a Cast Iron Platform

Flatness refers to how closely a surface conforms to a perfectly planar reference. On a cast iron platform, this ensures that parts remain stable and aligned during machining or inspection. Industry standards, such as ISO 8512-2 and DIN 876, classify flatness in grades, typically from Grade 0 (ultra-precise) to Grade 3 (general-purpose). Choosing the right grade depends on your application, whether for coordinate measuring machines (CMMs), precision tool setups, or assembly checks.

Why Flatness is Critical in Precision Work

Dimensional Consistency

Any unevenness in the platform surface can directly translate into dimensional errors, affecting part tolerances and assembly accuracy. High-precision machining often demands micron-level accuracy, making flatness indispensable.

Reliable Equipment Calibration

A level and planar platform provides a trusted reference for calibrating measuring instruments and machine tools. Without a consistent base, calibration results become unreliable.

Quality Assurance

Inspection and measurement require stable reference planes. A warped or uneven cast iron platform can lead to inaccurate readings, undermining quality control processes.

Factors That Influence Platform Flatness

Several variables can affect the flatness of a cast iron platform:

·Material Properties:

Premium gray cast iron offers superior vibration damping and thermal stability, reducing distortion.

·Environmental Conditions:

Heat fluctuations and humidity can cause slight expansions or contractions, affecting flatness.

·Load Distribution:

Uneven weight or concentrated loads can deform the surface over time.

·Wear and Usage:

Continuous contact with tools, workpieces, and chips gradually impacts surface uniformity.

Assessing Cast Iron Platform Flatness

Regular assessment is key to sustaining accuracy:

·Straightedge & Feeler Gauge:

Quick verification for general flatness checks.

·Precision Levels:

Detect small deviations for workshop-level accuracy.

·Laser Measurement & Electronic Levels:

Suitable for high-precision industrial setups, ensuring micron-level flatness verification.

Regular checks should align with your maintenance schedule and the precision requirements of your projects.

Maintenance Practices to Preserve Flatness

Maintaining a cast iron platform prolongs its usability and accuracy:

·Surface Cleaning:

Remove chips, dust, and residue after each use to prevent abrasion.

·Rust Protection:

Apply anti-corrosion coatings or light oil to prevent oxidation.

·Avoid Overloading:

Stay within the platform’s load limits to prevent permanent warping.

·Periodic Resurfacing:

For ultra-precise applications, lapping or scraping can restore flatness.

Common Mistakes That Reduce Flatness

·Ignoring Environmental Effects:

Exposure to heat or moisture can subtly deform the platform.

·Improper Support:

Platforms must rest on calibrated supports to maintain a stable reference plane.

·Neglecting Routine Checks:

Flatness degradation often remains unnoticed until critical errors occur.

Conclusion: Flatness as the Foundation of Precision

A cast iron platform is the backbone of precision machining, not just a supporting surface. Flatness ensures dimensional accuracy, reliable calibration, and effective quality control. By understanding its importance, routinely assessing flatness, and following proper maintenance protocols, manufacturers can ensure consistent high-quality performance.

For any machining workshop, investing in a high-quality, flat cast iron platform is essential to achieving precise, repeatable results.

References

GB/T 7714:Hapiddin A, Novyanto O, Azzumar M, et al. The Surface Plate Calibration Comparison Based on The Grid Method[J]. 2023.

MLA:Hapiddin, Asep, et al. "The Surface Plate Calibration Comparison Based on The Grid Method." (2023): 1819-1825.

APA:Hapiddin, A., Novyanto, O., Azzumar, M., Syahadi, M., Munir, M., Basuki, B., & Wiriadinata, H. (2023). The Surface Plate Calibration Comparison Based on The Grid Method.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province