News Detail

Why Granite Platforms Are the Benchmark for Precision Measurement

author:hxrtools Time:2025-08-28 15:46:27 Click:54

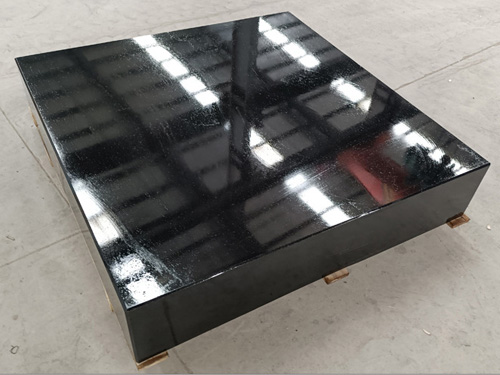

Granite Platform: The Gold Standard for Precision

In the world of dimensional accuracy, the granite platform stands as an indispensable tool. Unlike regular surfaces, it provides a stable, vibration-resistant base crucial for precision measurements and quality control. Even the smallest deviation in surface integrity can compromise tolerances, leading to costly errors in machining or inspection processes.

So, what makes the granite platform so exceptional? Let’s explore its unique attributes and why it remains the preferred choice in advanced manufacturing and metrology environments.

What Makes Granite Platforms Superior?

1. Unmatched Flatness and Rigidity

A defining characteristic of granite is its inherent stability. It resists bending, warping, and thermal expansion far better than metallic alternatives. This guarantees a consistently flat working surface, essential for ultra-precise tasks such as CMM calibration, gauge testing, and assembly alignment.

2. Thermal and Chemical Stability

Granite’s low thermal conductivity minimizes dimensional changes caused by temperature fluctuations. Additionally, it remains unaffected by most oils, coolants, and acids, ensuring that surface accuracy isn’t compromised in harsh industrial conditions.

3. Durability with Minimal Upkeep

Unlike metal surfaces that rust or degrade over time, granite maintains its structural integrity for years with minimal maintenance. A quick cleaning routine and basic protection measures are often enough to keep it in peak condition.

Key Applications of Granite Platforms

Granite platforms are integral in various precision-driven sectors:

·Inspection and Quality Assurance: Provides a stable reference plane for dimensional checks and verification of machined components.

·Tool and Instrument Calibration: Serves as a trusted standard for calibrating high-precision equipment.

·Machining Setup: Offers a reliable base for layout and assembly, reducing cumulative errors during production.

How to Choose the Right Granite Platform

When investing in a granite platform, consider these factors:

·Size and Load Capacity: Match the platform’s dimensions to your workspace and project requirements.

·Accuracy Grade: For ultra-precise work, choose Grade 0 or Grade 1 in compliance with ISO or DIN standards.

·Surface Finish: A lapped finish ensures smoother contact for measurement setups.

·Support System: Use calibrated stands or vibration-damping frames to maintain stability during operations.

Maintenance Guidelines for Long-Term Accuracy

To maximize performance and longevity:

1.Daily Cleaning: Remove metal chips, dust, and residue to avoid micro-abrasions.

2.Rust and Contaminant Prevention: While granite is non-corrosive, oils and chemicals should still be wiped clean.

3.Avoid Overloading: Respect weight limits to prevent stress-induced deformation.

4.Periodic Recalibration: Use precision instruments or laser systems for regular flatness checks.

5.Environmental Control: Avoid extreme heat, moisture, and vibrations that could affect measurement consistency.

Common Mistakes to Avoid

·Improper Support: Uneven bases can introduce distortion.

·Skipping Inspections: Flatness issues often develop slowly and go unnoticed until accuracy is compromised.

·Impact Damage: Dropping heavy tools can cause chips that alter measurement reliability.

Why Granite Remains the Industry Benchmark

In metrology and advanced manufacturing, the granite platform isn’t just a convenience—it’s a necessity. Its inherent stability, resistance to environmental changes, and long-term durability make it superior to metallic options. For anyone committed to achieving repeatable, high-precision outcomes, a granite platform is the foundation of success.

Invest in a top-grade granite platform, follow proper maintenance, and you’ll have a reference surface that supports accuracy for decades.

References

GB/T 7714:Skattum G A. Estimating thermal effects for granite surface plate calibration[J]. NCSLI Measure, 2015, 10(1): 50-58.

MLA:Skattum, Gordon A. "Estimating thermal effects for granite surface plate calibration." NCSLI Measure 10.1 (2015): 50-58.

APA:Skattum, G. A. (2015). Estimating thermal effects for granite surface plate calibration. NCSLI Measure, 10(1), 50-58.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province