News Detail

Top Welding Table Features You Should Never Overlook

author:hxrtools Time:2025-09-04 16:25:36 Click:187

The Importance of the Welding Table

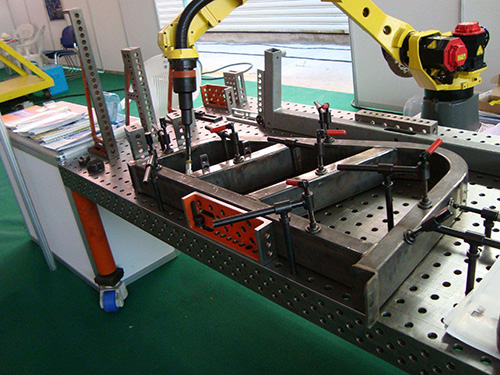

Every welder knows that precision begins with stability. The foundation for every high-quality weld isn’t just skill—it’s the Welding Table. More than a flat surface, this essential tool supports accuracy, efficiency, and safety. Overlooking its critical features can mean misaligned joints, wasted effort, or even hazardous conditions. That’s why knowing what makes a Welding Table truly effective is crucial for anyone serious about welding.

What a Welding Table Does in Fabrication

A Welding Table acts as the central hub for cutting, assembling, and welding tasks. Unlike ordinary benches, it is engineered to withstand extreme heat, heavy parts, and repeated use. Its structure combines strength and adaptability, giving welders the confidence to handle complex projects without worrying about instability.

From securing parts with clamps to providing grounding for safe electrical flow, the Welding Table is an essential part of modern workshops.

Essential Features of a Reliable Welding Table

1. Flatness and Rigidity

Accuracy begins with a flat surface. A Welding Table made from thick steel or cast iron provides the rigidity needed to resist warping, ensuring each project starts with a true and level base.

2. Heat Tolerance

Since welding generates intense thermal energy, the surface must be capable of withstanding repeated exposure to high temperatures. A well-built Welding Table disperses heat effectively, keeping its structure intact over time.

3. Slotting or Perforated Design

T-slots or evenly spaced holes give welders the flexibility to mount clamps, jigs, and fixtures wherever needed. This feature reduces setup adjustments and ensures that workpieces stay firmly in place during welding.

4. Adjustable and Ergonomic Design

Welding can involve long hours of work. A table with adjustable height makes it easier to maintain comfortable working positions, which boosts precision while reducing fatigue.

5. Electrical Grounding Points

For safe and efficient operations, a Welding Table should have grounding options integrated into its design. Proper grounding not only protects the welder but also improves weld consistency.

6. Modular and Portable Options

Workshops often deal with varying project sizes. Modular setups and mobile Welding Tables allow greater flexibility, making it easier to adapt to changing tasks without compromising stability.

7. Durability for Long-Term Use

Heavy-duty construction ensures that the Welding Table can withstand sparks, slag, and weighty components for years, reducing the need for frequent replacements.

Why These Features Matter

Choosing the right Welding Table brings direct benefits:

·Precision and Consistency: A stable surface supports cleaner welds and reduces distortion.

·Safety Assurance: Proper grounding and heat-resistant surfaces protect the welder and the work.

·Efficiency Gains: Faster setups mean more time spent welding, less on adjustments.

·Longevity: Durable materials ensure years of reliable service.

·Adaptability: Modular and ergonomic designs meet the needs of diverse projects.

Caring for Your Welding Table

To keep a Welding Table performing at its best, regular upkeep is key:

·Clean Frequently: Remove debris and spatter after each session.

·Apply Protection: Light coatings of oil or anti-rust sprays prevent corrosion.

·Check Levelness: Verify flatness occasionally to ensure ongoing accuracy.

·Maintain Slots and Holes: Keep them free of damage for precise clamping.

·Respect Load Limits: Overloading can compromise long-term performance.

With consistent care, a Welding Table will remain a reliable partner for all your fabrication needs.

Conclusion: Welding Table as a Core Workshop Tool

A Welding Table is not just another piece of shop furniture—it’s the foundation of every precise and safe weld. Its features, from flatness and heat resistance to grounding and modular design, directly shape the outcome of welding projects.

By investing in a well-designed Welding Table, welders ensure greater accuracy, improved safety, and long-term value. Ignoring these key elements risks compromising both productivity and results. For anyone serious about welding, a high-quality Welding Table is a tool you should never overlook.

References

GB/T 7714:Arifin F, Arnoldi D, Effendi S, et al. Design Simulation of Upper Arm on Welding Table[J]. International Journal of Mechanics, Energy Engineering and Applied Science (IJMEAS), 2023, 1(1): 7-11.

MLA:Arifin, Fatahul, et al. "Design Simulation of Upper Arm on Welding Table." International Journal of Mechanics, Energy Engineering and Applied Science (IJMEAS) 1.1 (2023): 7-11.

APA:Arifin, F., Arnoldi, D., Effendi, S., Herlambang, Y. D., Fadilah, M. A., & Radjiq, A. (2023). Design Simulation of Upper Arm on Welding Table. International Journal of Mechanics, Energy Engineering and Applied Science (IJMEAS), 1(1), 7-11.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province