News Detail

How to Choose the Right Cast Iron Platform for Heavy-Duty Applications

author:hxrtools Time:2025-09-07 16:34:44 Click:65

The Role of Cast Iron Platform in Industry

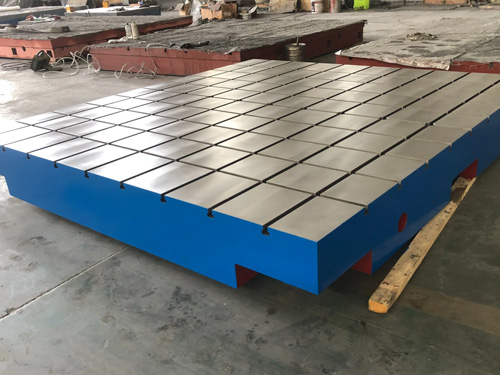

In demanding industrial environments, equipment must combine strength with precision. A Cast Iron Platform is widely regarded as a foundation for heavy-duty operations thanks to its ability to handle extreme loads, resist wear, and maintain accuracy under stress. Whether in machining centers, inspection setups, or fabrication workshops, choosing the right platform can make a significant difference in performance and productivity.

This guide explores what to look for when selecting a Cast Iron Platform so you can make an informed decision for long-term reliability.

Why Cast Iron Platforms Stand Out

Before comparing specifications, it helps to understand why cast iron remains the preferred choice in many applications:

·Superior strength – Cast iron’s dense composition makes it ideal for supporting large weights.

·Thermal stability – It maintains flatness despite exposure to heat and fluctuating temperatures.

·Vibration absorption – Natural damping properties minimize vibration transfer, preserving accuracy.

·Extended lifespan – Resistant to wear and mechanical stress, it provides reliable service for years.

These qualities make cast iron unmatched in scenarios where both endurance and precision are required.

Essential Factors in Choosing the Right Cast Iron Platform

1. Load Requirements

Determine the maximum weight capacity your platform must sustain. For machining large workpieces or supporting heavy assemblies, thicker castings and reinforced rib designs are essential.

2. Flatness and Accuracy Standards

For inspection and metrology tasks, the flatness grade of the platform is critical. Platforms manufactured to recognized tolerance standards (such as DIN 876) provide the accuracy necessary for precision work.

3. Dimensions and Workspace Fit

The platform size should correspond to your specific application. Larger platforms are suited for oversized components, while compact ones can fit into limited workspaces. Some models allow for custom dimensions or modular adjustments.

4. Ribbing and Internal Structure

The rib layout beneath the surface determines how effectively the platform distributes loads. Stronger ribbing prevents deformation and ensures long-term durability under continuous use.

5. Environmental Suitability

If the platform will encounter cutting fluids, oils, or temperature variation, ensure that the chosen cast iron grade is resistant enough for those conditions.

6. Functional Enhancements

Depending on usage, you may require features such as:

·T-slots for flexible clamping and fixture placement.

·Threaded inserts or holes for specialized tooling.

·Adjustable bases to modify working height or leveling.

Where Cast Iron Platforms Are Commonly Used

The versatility of a Cast Iron Platform makes it valuable across multiple sectors:

CNC machining foundations – Provides stability for precision milling, turning, or drilling.

Welding and fabrication bases – Withstands high heat without losing shape.

Inspection and calibration – Serves as a reference surface for accurate measurement.

Assembly lines – Functions as a stable, vibration-free foundation for delicate operations.

Tips for Maintenance and Longevity

Even though a Cast Iron Platform is built for strength, routine care is necessary to maintain its performance:

·Regular cleaning – Remove metal chips, dust, and coolant residues promptly.

·Protective coating – Apply rust-preventive oil to safeguard against corrosion.

·Avoid impacts – Heavy objects should not be dropped directly on the surface.

·Recalibration – Schedule periodic inspections to ensure flatness and accuracy remain intact.

Conclusion: A Smart Investment in Cast Iron Platform

A carefully selected Cast Iron Platform serves as more than just a work surface — it becomes the backbone of industrial precision. From evaluating load capacity and ribbing structure to ensuring environmental resistance, each factor contributes to performance and longevity.

By investing wisely in the right Cast Iron Platform, you secure not only the strength to handle heavy-duty tasks but also the accuracy to deliver consistent results for years to come.

References

GB/T 7714:Kováčiková P, Vavro J, Vavro jr J, et al. Measuring of vibration-damping properties of cast iron[J]. Manufacturing technology, 2018, 18(1): 57-59.

MLA:Kováčiková, Petra, et al. "Measuring of vibration-damping properties of cast iron." Manufacturing technology 18.1 (2018): 57-59.

APA:Kováčiková, P., Vavro, J., Vavro jr, J., & Dubec, A. (2018). Measuring of vibration-damping properties of cast iron. Manufacturing technology, 18(1), 57-59.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province