News Detail

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

author:hxrtools Time:2025-11-18 12:25:34 Click:100

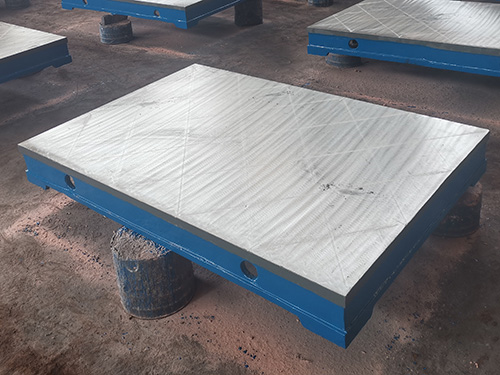

As a China cast iron platform manufacturer with bulk supply capabilities, we understand that surface treatment is one of the most decisive factors in ensuring dimensional accuracy and long-term durability.

Cast iron platforms are widely used in precision measurement, machinery setup, and industrial testing, but their performance depends heavily on how well their surfaces are prepared and protected.

This article explains several proven surface treatment processes that improve the functionality, resistance, and lifespan of cast iron platforms used in manufacturing environments.

1. Importance of Proper Surface Treatment

Raw cast iron is strong but chemically reactive. When exposed to humidity or oxygen, its surface easily oxidizes, forming rust and reducing flatness over time.

Applying the right treatment provides multiple benefits:

·Prevents oxidation and corrosion

·Maintains measurement accuracy over years of use

·Improves coating adhesion and mechanical strength

·Enhances resistance to vibration and temperature variation

For a Cast Iron Platform designed for precise calibration and load-bearing tasks, surface stability is just as critical as structural strength.

2. Primary Surface Treatment Processes

(1) Stress Relief and Aging

Before any machining begins, the platform blank must undergo thermal stress relief or natural aging.

This procedure allows the internal stresses generated during casting to dissipate gradually, preventing future deformation.

Many China factories use a combination of heat treatment and vibration aging to stabilize the material before precision grinding, ensuring reliable dimensional integrity.

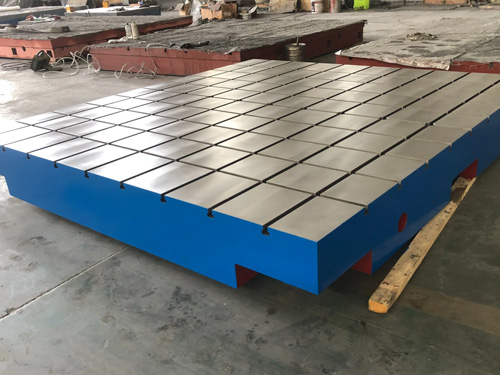

(2) Precision Grinding

After stress relief, the platform enters the grinding phase.

High-precision surface grinders remove the rough layer and produce a flat, smooth plane.

For industrial-grade platforms, the grinding tolerance is typically kept within 0.01 mm/m, while metrology-grade platforms require even tighter precision.

Proper grinding ensures the platform remains level during long-term use, even under heavy mechanical load.

(3) Hand Scraping

Once grinding is completed, many manufacturers still rely on manual scraping — a fine finishing method that adjusts micro-level imperfections.

Scraping improves flatness, provides even contact points, and enhances lubrication retention between surfaces.

Although this is a labor-intensive process, skilled technicians in China’s precision tool factories continue to apply it because it delivers unmatched surface quality for inspection and assembly platforms.

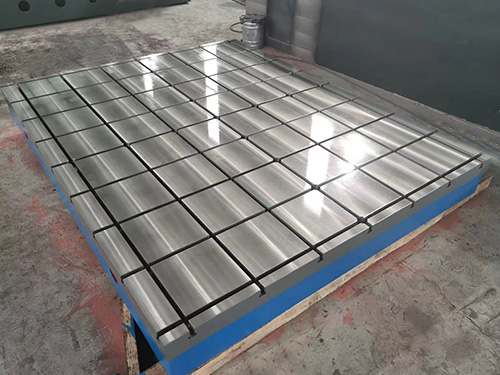

(4) Polishing and Surface Refinement

Polishing follows scraping to enhance appearance and minimize micro-roughness.

This can be performed mechanically, chemically, or electrochemically depending on the surface finish required.

A polished cast iron platform is not only aesthetically appealing but also easier to clean and less prone to dust accumulation.

In industries like aerospace or metrology, this step directly contributes to long-term accuracy.

(5) Protective Coating Application

After the mechanical treatments, protective coatings are applied to safeguard the surface against corrosion, oil, or chemical exposure.

Common protective layers include:

·Anti-rust oils or waxes for short-term storage protection.

·Epoxy and enamel coatings for durable, long-term corrosion resistance.

·Powder coatings that combine hardness and visual uniformity.

Coatings also serve a functional purpose by differentiating product models or quality grades through color markings.

(6) Optional Surface Hardening

For platforms exposed to abrasive environments or heavy mechanical stress, flame hardening or induction hardening can be used to strengthen the working surface.

This treatment enhances wear resistance while maintaining the platform’s dimensional precision.

A properly hardened surface can reach up to HRC 55, ensuring exceptional longevity.

3. Modern Innovations in Surface Finishing

In recent years, new technologies have elevated the surface treatment of cast iron platforms beyond traditional methods.

Some notable advancements include:

·Laser texturing for improved oil retention and friction control

·Nano-ceramic coatings for superior anti-rust protection

·Automated polishing systems that ensure consistent finish quality

These modern processes allow China suppliers to produce cast iron platforms that comply with international standards like DIN 876, GB/T 22095, and ISO 8512.

4. Maintenance and Long-Term Care

Even the best-treated cast iron surface requires proper maintenance.

Here are several practical steps users can follow:

·Keep the surface clean and lightly oiled to prevent oxidation

·Avoid prolonged contact with moisture or acids

·Use protective covers when the platform is not in use

·Reapply anti-rust oil after long idle periods

Routine maintenance ensures the platform retains its precision and appearance throughout its service life.

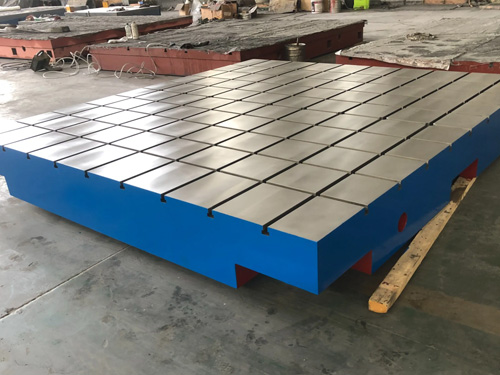

5. Selecting a Reliable Manufacturer

When sourcing cast iron platforms, it’s essential to evaluate not only the machining precision but also the quality of the surface treatment.

A trustworthy supplier should:

·Provide inspection data for flatness and hardness

·Apply consistent coating and protection before shipment

·Support OEM customization and large-volume production

·Ensure material traceability and compliance with global standards

Working directly with a China cast iron platform factory guarantees consistent quality control, shorter lead times, and competitive pricing for bulk orders.

6. Final Thoughts

A well-treated surface is the foundation of every reliable Cast Iron Platform.

From stress relief to polishing and coating, each process contributes to long-term performance, corrosion resistance, and precision stability.

As a China manufacturer providing bulk cast iron platform supply, we continuously improve our surface treatment technologies to meet the demands of global industries — from heavy machinery alignment to laboratory calibration.

By investing in proper surface finishing and regular maintenance, users can extend platform lifespan, improve measurement accuracy, and reduce total operational costs.

In every application, the surface tells the story of the platform’s quality — and with the right treatment, that story lasts for decades.

References

GB/T 7714:Paczkowska M. Modification of the Surface Layer of Grey Cast Iron by Laser Heat Treatment[J]. Lubricants, 2024, 12(12): 457.

MLA:Paczkowska, Marta. "Modification of the Surface Layer of Grey Cast Iron by Laser Heat Treatment." Lubricants 12.12 (2024): 457.

APA:Paczkowska, M. (2024). Modification of the Surface Layer of Grey Cast Iron by Laser Heat Treatment. Lubricants, 12(12), 457.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province