News Detail

Flexible Welding Tooling Solutions from China Manufacturer

author:hxrtools Time:2025-11-12 09:40:09 Click:157

Every successful fabrication process begins with the right foundation — reliable and adaptable tooling. Among the most innovative solutions in recent years is flexible welding tooling, a modular system designed to streamline production, enhance weld accuracy, and reduce downtime.

For workshops seeking cost-effective solutions that support multiple production types, flexible welding tooling sourced from a China manufacturer or China supplier with bulk supply capability offers a balance of performance, versatility, and affordability that traditional fixtures simply cannot match.

1. Understanding Flexible Welding Tooling

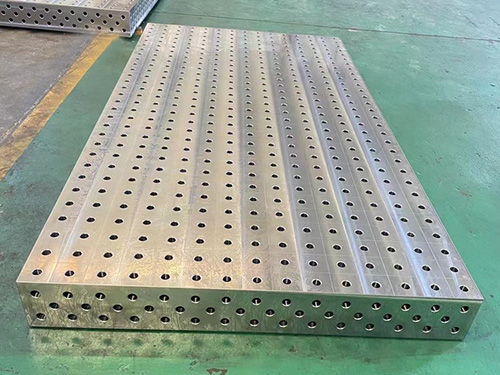

A flexible welding tooling system is a reconfigurable workholding platform that replaces the need for multiple fixed jigs. It consists of modular steel or cast iron plates, precision grid holes, positioning blocks, and clamping units that can be rearranged to suit different welding projects.

Instead of building a new fixture for every product, operators can assemble and modify setups within minutes. This flexibility allows workshops to handle a wide range of part geometries and production volumes — from prototypes to large-scale assemblies — using a single system.

2. How Flexible Tooling Increases Workshop Efficiency

a. Fast Setup and Reconfiguration

Traditional welding fixtures often require hours of preparation. Flexible tooling, however, allows quick adjustments using standard locating pins and clamping accessories. This drastically cuts setup time and accelerates production cycles.

b. Greater Accuracy and Repeatability

Precision-machined holes and surfaces ensure consistent alignment between components. The result is higher welding accuracy, minimal distortion, and fewer defects — crucial for industries where tolerances are tight and consistency matters.

c. Reduced Labor and Production Costs

Because the same system can be adapted for multiple tasks, workshops save on design, material, and labor costs associated with custom fixtures. Over time, this leads to measurable financial savings and improved resource utilization.

d. Safer and More Ergonomic Operation

Flexible tooling systems are designed with stability and operator comfort in mind. Secure clamping and adjustable heights reduce fatigue and improve safety during prolonged welding operations.

3. Essential Features of a High-Quality Flexible Welding Tooling System

When choosing a system for your workshop, several characteristics determine performance and longevity:

·High-Strength Material: Heat-treated steel or cast iron ensures rigidity and resistance to thermal deformation.

·Precision Machining: Surface flatness and hole accuracy guarantee precise positioning.

·Modular Design: Components can be assembled into various configurations, adapting easily to different part shapes.

·Scalable Structure: Tables can be joined together for large assemblies or divided for smaller tasks.

·Universal Compatibility: Suitable for manual, semi-automatic, or robotic welding setups.

A robust flexible welding tooling system becomes the backbone of modern metal fabrication, ensuring dependable quality across all projects.

4. Why Choose a China Manufacturer for Bulk Supply

As manufacturing technology advances, China manufacturers have become leading suppliers of flexible welding tooling worldwide. Their expertise and large-scale production offer several compelling benefits:

·Consistent Bulk Supply: Equipped with automated machining centers and precision foundries, Chinese factories deliver stable, high-volume production while maintaining tight quality control.

·Competitive Pricing: Direct factory sourcing reduces costs without compromising durability or accuracy.

·OEM/ODM Customization: Manufacturers can tailor table sizes, grid spacing, or surface finishes according to specific engineering requirements.

·International Quality Standards: Many follow ISO and CE certifications, supported by surface flatness and load-bearing test reports.

Partnering with a China manufacturer offering bulk flexible welding tooling supply guarantees long-term cost efficiency, reliable performance, and scalable production support.

5. Industrial Applications of Flexible Welding Tooling

The adaptability of flexible tooling makes it indispensable across numerous industries:

·Automotive Manufacturing: For assembling frames, brackets, and exhaust components.

·Aerospace and Defense: Used in lightweight structure welding where accuracy is crucial.

·Heavy Equipment and Construction: Enables assembly of large, complex metal frames.

·Automation and Robotics: Integrates easily with robotic welding arms for repetitive, high-precision production.

·Custom Fabrication and Prototyping: Ideal for short runs and R&D departments needing frequent design adjustments.

By incorporating flexible welding tooling, workshops gain the freedom to adapt quickly to new product designs, production schedules, and automation systems.

6. Maintenance for Longevity and Accuracy

To ensure your tooling continues to perform optimally:

·Clean surfaces and grid holes after each job to remove spatter or metal debris.

·Apply anti-corrosion oil periodically to protect against oxidation.

·Inspect clamping elements for wear and replace as needed.

·Store modular components in dry, organized areas to avoid damage.

Regular maintenance extends the lifespan of the system, ensuring reliable performance for years of continuous use.

Conclusion: The Future of Workshop Productivity Lies in Flexibility

In the era of smart manufacturing and rapid customization, flexible welding tooling represents a turning point in workshop efficiency. It enables faster production changeovers, improved welding precision, and significant cost savings — all while maintaining safety and stability.

For businesses seeking dependable and scalable solutions, sourcing flexible welding tooling from a professional China manufacturer with bulk supply capacity is a proven way to secure consistent quality and value.

A flexible tooling system isn’t just equipment — it’s an investment in productivity, adaptability, and long-term success for modern fabrication workshops.

References

GB/T 7714:Fan W, Zheng L, Wang Y. An automated reconfigurable flexible fixture for aerospace pipeline assembly before welding[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(9): 3791-3811.

MLA:Fan, Wei, Lianyu Zheng, and Yahui Wang. "An automated reconfigurable flexible fixture for aerospace pipeline assembly before welding." The International Journal of Advanced Manufacturing Technology 97.9 (2018): 3791-3811.

APA:Fan, W., Zheng, L., & Wang, Y. (2018). An automated reconfigurable flexible fixture for aerospace pipeline assembly before welding. The International Journal of Advanced Manufacturing Technology, 97(9), 3791-3811.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province