News Detail

Fully Fabricated Welding Tables for Heavy-Duty Industrial Applications

author:hxrtools Time:2025-12-12 19:40:29 Click:168

A fully fabricated welding table plays a foundational role in many industrial welding environments where reliability, structural stability, and repeatable precision are required every day. As large-scale fabrication tasks become more complex and industrial expectations rise, a growing number of workshops now seek welding platforms engineered from robust steel assemblies rather than lightweight or modular alternatives. Fully fabricated tables, produced through reinforced steel construction and solid welding processes, offer the strength and accuracy needed for heavy workloads and demanding production lines.

This article explores how these tables support heavy-duty applications, what features define a high-performance welding platform, and why choosing a capable Manufacturer with consistent Production capacity ensures long-term value for industrial facilities.

Why Fully Fabricated Welding Tables Excel in Tough Industrial Environments

1. Structural Strength for Heavy Components

Many industrial operations handle oversized steel sections, thick plates, and multi-piece assemblies that apply tremendous pressure to the work surface. A fully fabricated welding table is designed with welded frames, solid steel plates, and braced structural members that maintain their integrity under high stress.

This construction prevents wobbling, surface distortion, and vibration—issues that can compromise weld quality or reduce precision in alignment tasks.

2. Accurate Working Surfaces for Dimensional Consistency

The flatness of the work surface is one of the strongest advantages of a fully fabricated welding table. These tables typically utilize machined or precision-processed steel plates that provide:

·A reliable foundation for clamping systems

·Repeatable reference points for high-accuracy fabrication

·Decreased part distortion during welding

·Reduced rework due to alignment issues

In industries where specific angles, parallel surfaces, or repeatable part geometry matter, the stability of the table directly influences production consistency.

3. Designed for Long-Term Durability

Heavy-duty fabrication involves continuous exposure to steel impact, welding heat, grinding sparks, and mechanical load. Fully fabricated welding tables resist damage far more effectively than lighter alternatives.

Their all-steel construction ensures minimal deformation even after long-term thermal cycling. This durability is especially valuable for fabrication plants, mechanical workshops, and facilities operating multiple shifts with constant welding activities.

Core Structural Features of Fully Fabricated Welding Tables

1. Welded Steel Frames and Bracing

To achieve the rigidity required for heavy industrial use, these tables rely on fully welded frames rather than bolt assembly. Reinforced ribs and cross-bracing provide the internal strength needed to carry substantial loads while maintaining structural stability.

2. Industrial-Grade Steel Plate Surfaces

The tabletop is commonly produced from:

·Thick structural steel

·Hardened plate steel

·Specialty tooling plate

By using high-strength materials, the tabletop remains flat and stable even when subjected to welding heat and repetitive mechanical force.

3. Compatibility with Fixturing and Clamping Systems

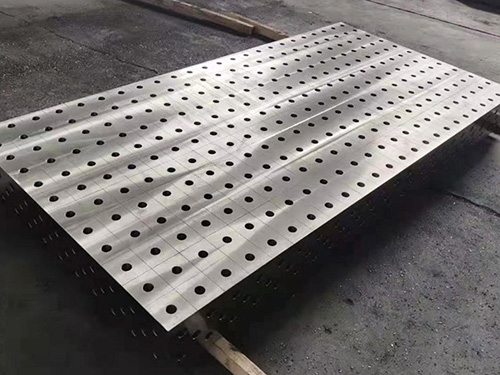

While not all tables require modular grids or slots, many fully fabricated designs integrate:

·T-slots

·Hole grids

·Custom fixture points

This enhances flexibility and supports diverse fabrication requirements, from straight-line assemblies to multi-angle structures.

4. High Load-Bearing Capacity

A major advantage of fully fabricated welding tables is their ability to support extremely heavy parts.

Whether it’s machinery frames, steel beams, or industrial brackets, these tables are engineered to handle concentrated loads without bending or tilting.

Where Fully Fabricated Welding Tables Deliver the Most Value

1. Structural Steel Manufacturing

Factories constructing large assemblies such as beams, building frames, or welded support structures rely on rigid welding platforms to maintain geometry and alignment.

2. Automotive & Trailer Fabrication

Chassis, heavy frames, and large welded modules require consistent reference surfaces to maintain dimensional accuracy throughout the Production process.

3. Marine & Shipyard Welding Tasks

Ship panels, thick steel components, and oversized modules demand welding surfaces that resist deformation and provide long-term stability.

4. Machinery and Equipment Assembly

Workshops building conveyor systems, machine housings, or industrial mechanical structures benefit from stable fixturing and large surface areas.

5. Metal Architectural Fabrication

Applications such as steel staircases, custom metal frames, and architectural structures rely heavily on accurate welding platforms to maintain visual and structural quality.

Choosing a Manufacturer for Fully Fabricated Welding Tables

Selecting the right Manufacturer for a fully fabricated welding table is as important as the table's design. Industrial buyers should evaluate:

1. Production Capabilities for Heavy Steel Structures

A professional manufacturer should have:

·CNC cutting equipment

·Heavy plate processing

·Surface machining

·Full welding and stress relief systems

These capabilities ensure the table is produced consistently and can withstand long-term industrial use.

2. Verified Material Types and Structural Reliability

Reliable suppliers should be able to provide steel grade documentation, surface processing details, and load-bearing data. These technical records help ensure the table meets industrial safety and durability requirements.

3. Surface Flatness and Quality Standards

Surface precision—whether following DIN standards or custom tolerances—greatly influences how well the table supports complex assemblies.

4. Custom Production Options

Because manufacturing workflows vary widely, the ideal manufacturer must offer:

·Custom dimensions

·Adjustable leg options

·Grid layouts or slot systems

·Enhanced surface treatments

This allows the table to fit perfectly within the user’s production environment.

5. Long-Term Reliability and Support

After-sales service, replacement accessories, and technical assistance help extend the lifecycle of the welding table and protect the investment of industrial users.

Conclusion

A fully fabricated welding table is one of the most valuable assets in any facility that handles heavy-duty welding or industrial fabrication. Its stability, strength, and precision help maintain consistent production quality while supporting the long-term efficiency of large-scale operations. When sourced from a capable Manufacturer with strong Production capabilities, such a table becomes a durable, dependable foundation for demanding fabrication tasks.

For workshops seeking accuracy, safety, and structural reliability, investing in a fully fabricated welding table is a strategic decision that delivers lasting performance in even the most intensive industrial environments.

References

GB/T 7714:Messler Jr R W. Principles of welding: processes, physics, chemistry, and metallurgy[M]. John Wiley & Sons, 2024.

MLA:Messler Jr, Robert W. Principles of welding: processes, physics, chemistry, and metallurgy. John Wiley & Sons, 2024.

APA:Messler Jr, R. W. (2024). Principles of welding: processes, physics, chemistry, and metallurgy. John Wiley & Sons.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province