News Detail

High Precision and Longevity from Chinese Manufacturers

author:hxrtools Time:2025-10-18 13:48:19 Click:120

For metal fabrication professionals and workshop enthusiasts, a welding table is more than just a working surface—it is the foundation for accuracy, safety, and efficiency. Selecting the right table can drastically impact your welding results, productivity, and overall project quality. This guide explores the essential features of welding tables and highlights the advantages of sourcing from reputable China manufacturers offering bulk supply and factory-direct options.

Understanding the Welding Table and Its Importance

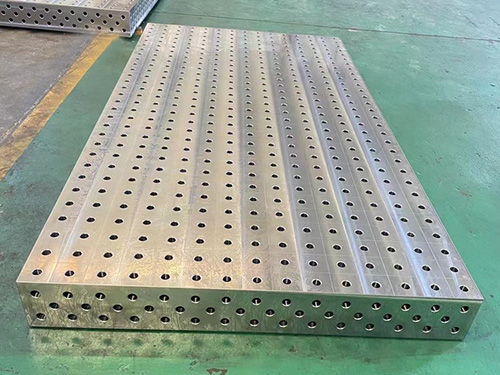

A welding table is specifically engineered to support metalwork projects during welding, cutting, or assembly processes. Unlike standard workbenches, these tables are designed to:

·Provide stable, heat-resistant surfaces that resist deformation.

·Include precision holes and slots for clamping and fixture setups.

·Support heavy loads, ensuring safety for large-scale metal fabrication.

Investing in a quality welding table guarantees more accurate welds, reduces mistakes, and enhances overall efficiency in your workshop.

Core Features to Consider

When evaluating welding tables, several critical attributes define their quality:

1.Construction Material

Premium welding tables are generally made of carbon steel or stainless steel, offering both sturdiness and longevity. Many China suppliers provide precision-ground surfaces to ensure flatness and durability.

2.Modularity

Versatile welding tables come with adjustable or removable clamps, fixtures, and slots, accommodating various welding and assembly tasks.

3.Weight Capacity

Industrial-grade tables are engineered to handle substantial loads, making them suitable for heavy metal projects without compromising stability.

4.Surface Precision

A machined flat surface is crucial for accurate assembly and consistent welding outcomes.

By carefully considering these features, you can select a welding table suited for both professional fabrication and serious hobbyist projects.

Why Chinese Manufacturers Are a Smart Choice

China has emerged as a leading hub for high-quality welding tables, thanks to its combination of precision engineering, cost-effective production, and large-scale supply capabilities.

·Factory-Direct Bulk Supply

Many China manufacturers offer direct-from-factory bulk options, which is ideal for workshops, industrial buyers, and distributors looking for competitive pricing.

·Custom Solutions

Suppliers frequently provide tailored dimensions, hole patterns, and surface finishes, allowing welding tables to meet specific operational needs.

·Durable and Reliable

Products from reputable Chinese factories meet international standards, ensuring precision, flatness, and longevity over years of use.

Choosing a trusted Chinese supplier guarantees access to high-quality, durable welding tables with convenient bulk supply options, streamlining procurement for professional use.

Maintaining Your Welding Table for Longevity

Proper maintenance can significantly extend the life and effectiveness of a welding table:

1.Regular Cleaning – Remove metal debris and slag to prevent surface damage.

2.Avoid Concentrated Heat – Excessive heat on one spot may warp the table over time.

3.Check Flatness Periodically – Ensures welding precision is maintained.

4.Use Appropriate Fixtures – Correct clamps and jigs protect the surface and improve stability.

Routine care not only preserves your investment but also supports consistent, high-quality welding results.

Choosing the Right Supplier

When sourcing a welding table, consider more than just the product:

·Manufacturer Reliability – Look for China factories with proven bulk supply records.

·Customizability – Ability to tailor tables to specific project requirements.

·Certifications and Standards – ISO or equivalent quality certifications indicate dependable production.

·Efficient Logistics – Timely delivery is key, especially for bulk orders.

Selecting the right manufacturer ensures that you receive a reliable, high-quality welding table while simplifying procurement for multiple units.

Conclusion

A welding table is the cornerstone of accurate, durable, and efficient metal fabrication. By focusing on robust materials, precision surfaces, and versatile design, you ensure every welding project is executed flawlessly. Sourcing from reputable China manufacturers with factory-direct bulk supply options guarantees both cost-effectiveness and long-term reliability.

Investing in a premium welding table from a trusted Chinese supplier enhances workshop efficiency, accuracy, and durability—making it a strategic tool for professionals and industrial buyers alike.

References

GB/T 7714:Suryanto A E, Lumbantobing M A, Murwantini S, et al. Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision[J]. G-Tech: Jurnal Teknologi Terapan, 2025, 9(1): 29-39.

MLA:Suryanto, Ahmad Eko, et al. "Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision." G-Tech: Jurnal Teknologi Terapan 9.1 (2025): 29-39.

APA:Suryanto, A. E., Lumbantobing, M. A., Murwantini, S., Samudra, A., & Supriyadi, S. (2025). Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision. G-Tech: Jurnal Teknologi Terapan, 9(1), 29-39.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province