News Detail

How Cast Iron Platforms Improve CNC Milling Accuracy

author:hxrtools Time:2025-12-31 12:56:23 Click:194

How Cast Iron Platforms Improve CNC Milling Accuracy

A Cast Iron Platform plays a critical role in modern CNC milling operations, directly influencing machining precision, surface finish, and long-term equipment stability. While cutting tools, control systems, and programming often receive the most attention, the structural foundation beneath the machine is equally important.

As a Cast Iron Platform manufacturer with stable production capability, designing platforms that consistently support high-precision machining requires a deep understanding of material behavior, vibration control, and manufacturing quality. This article explores how cast iron platforms improve CNC milling accuracy and why they remain a preferred solution in industrial production environments.

1. The Importance of Machine Foundations in CNC Milling

CNC milling accuracy depends on the machine’s ability to maintain positional stability under dynamic cutting forces. Even small deflections or vibrations at the foundation level can translate into dimensional errors on the finished part.

The platform serves as the base that supports the entire machine structure. A rigid and stable platform minimizes unwanted movement, allowing the CNC system to perform as programmed.

2. Why Cast Iron Is Widely Used for CNC Platforms

2.1 High Structural Rigidity

Cast iron offers excellent compressive strength and stiffness, making it ideal for supporting heavy CNC milling machines. Its rigid structure resists deformation under load, ensuring consistent alignment of machine components.

This rigidity is essential for maintaining tight tolerances during high-speed or heavy-duty milling operations.

2.2 Natural Vibration Damping Properties

One of the most significant advantages of cast iron is its inherent ability to damp vibrations. Compared to steel or fabricated structures, cast iron absorbs and dissipates vibrational energy more effectively.

Reduced vibration leads to smoother cutting action, improved surface finish, and enhanced tool life.

3. Vibration Control and Machining Accuracy

3.1 Cutting Forces and Dynamic Loads

During CNC milling, cutting forces fluctuate continuously as tools engage and disengage with the workpiece. These dynamic loads can excite vibrations in the machine structure if the platform lacks adequate damping.

A cast iron platform helps stabilize these forces, reducing chatter and maintaining consistent tool positioning.

3.2 Impact on Surface Quality

Excessive vibration often results in visible chatter marks and poor surface finish. By minimizing vibration transmission, cast iron platforms directly contribute to higher-quality machining results.

4. Thermal Stability and Dimensional Consistency

4.1 Thermal Behavior of Cast Iron

Thermal stability is another critical factor in CNC milling accuracy. Cast iron exhibits relatively low thermal expansion and distributes heat evenly across its structure.

This reduces the risk of localized distortion caused by temperature changes during extended machining cycles.

4.2 Maintaining Alignment Over Time

Consistent thermal behavior helps maintain machine alignment over long production runs. This stability is especially important in high-precision applications where even minor thermal shifts can affect dimensional accuracy.

5. Mass and Weight Advantages

The high mass of a cast iron platform contributes significantly to machine stability. Heavier platforms are less susceptible to movement caused by external vibrations or internal cutting forces.

This added mass acts as a mechanical anchor, allowing CNC machines to operate more smoothly and accurately.

6. Precision Manufacturing and Machining of Platforms

6.1 Casting Quality and Structural Integrity

The accuracy of a cast iron platform begins with the casting process itself. Proper mold design, controlled cooling, and stress relief treatments are essential to prevent internal defects and residual stresses.

Manufacturers with standardized production processes ensure consistent platform quality across multiple units.

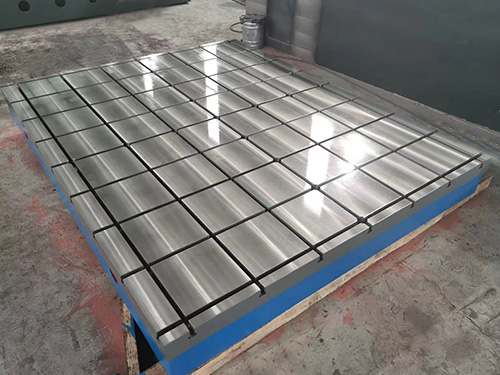

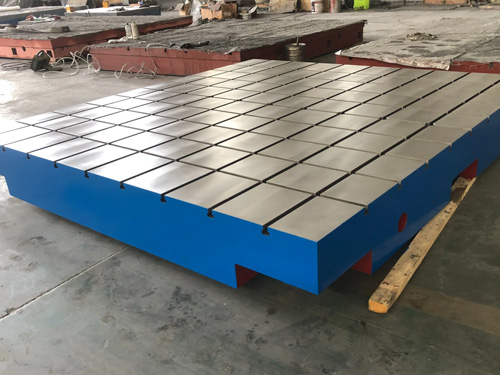

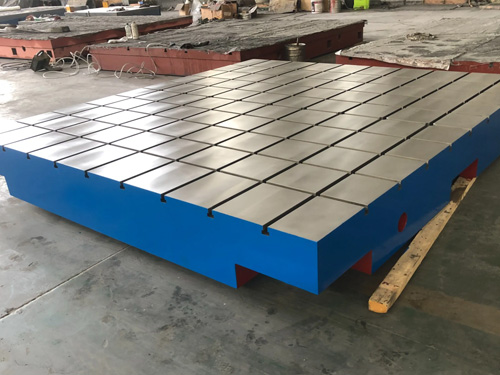

6.2 Machining and Surface Flatness

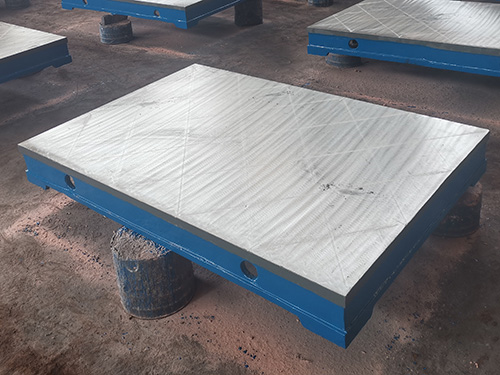

After casting, platforms undergo precision machining to achieve flatness and dimensional accuracy. High-quality surface finishing ensures proper machine installation and long-term stability.

7. Durability and Long-Term Performance

Cast iron platforms are known for their durability and resistance to wear. Unlike lighter materials, they maintain structural integrity even after years of continuous operation.

This durability reduces maintenance requirements and supports reliable performance in demanding production environments.

8. Benefits for Industrial Production Environments

In industrial settings where CNC machines operate continuously, platform stability directly affects productivity and part quality. Cast iron platforms help reduce downtime caused by vibration-related issues and rework.

For facilities running multiple machines, consistent platform performance across installations simplifies setup and process control.

Conclusion: Why Cast Iron Platforms Remain the Preferred Choice

Cast iron platforms provide a combination of rigidity, vibration damping, thermal stability, and durability that is difficult to match with alternative materials. These characteristics directly improve CNC milling accuracy and overall machining performance.

For organizations sourcing Cast Iron Platform solutions from a manufacturer with reliable production capacity and bulk supply capability, investing in high-quality platforms ensures consistent machining results and long-term operational stability. A well-designed cast iron platform is not just a support structure—it is a critical component of precision CNC milling systems.

References

GB/T 7714:Brecher C, Bäumler S, Guralnik A. Experimental modal analysis using a tracking interferometer[J]. CIRP Annals, 2014, 63(1): 345-348.

MLA:Brecher, Christian, Stephan Bäumler, and Alexander Guralnik. "Experimental modal analysis using a tracking interferometer." CIRP Annals 63.1 (2014): 345-348.

APA:Brecher, C., Bäumler, S., & Guralnik, A. (2014). Experimental modal analysis using a tracking interferometer. CIRP Annals, 63(1), 345-348.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province