News Detail

How Modular Welding Tables Revolutionize Workshop Efficiency

author:hxrtools Time:2025-12-25 11:47:47 Click:169

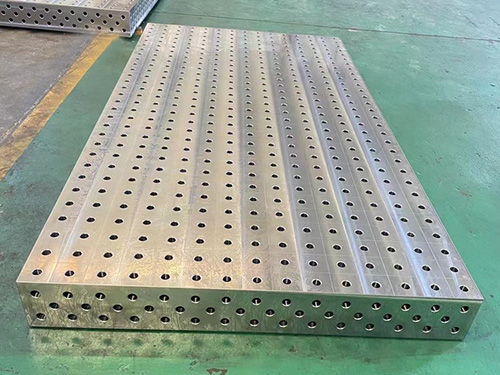

In every metal fabrication environment, the Welding Table plays a defining role in how efficiently projects move from preparation to completion. A stable, well-designed surface directly influences workflow speed, precision alignment, and consistency. Today’s modular welding tables represent a major step forward, offering a level of adaptability that traditional fixed tables simply cannot match. Backed by reliable manufacturer production standards, these systems provide the strength, versatility, and lifespan needed for demanding workshop conditions.

As workshops take on more diverse fabrication tasks, the ability to reconfigure workspaces quickly becomes critical. Modular welding tables answer this need by allowing welders to modify setups effortlessly, supporting both small-batch work and high-volume output.

Why the Modular Approach Outperforms Traditional Tables

Older welding tables often force welders to adapt their methods to the limitations of the surface. Modular tables reverse this relationship—welders gain complete control over layout, alignment, and part positioning.

1. Adjustable Fixtures Deliver Exceptional Accuracy

The precision benefits are immediately noticeable. With interchangeable fixtures, grid hole patterns, and customizable alignment points, welders can position materials with near-perfect repeatability. This leads to cleaner welds and fewer measurement errors.

Whether fabricators are assembling frames, brackets, or custom metal structures, modular tables provide the fine control required for professional-grade accuracy.

Streamlined Workflow and Faster Project Turnaround

Productivity is a core priority in any workshop. Modular welding tables significantly reduce wasted time, especially during preparation and material setup.

2. Reduced Setup Effort Saves Hours Over Time

With a modular system, clamps, angles, and stops lock into place with minimal adjustment. The pre-engineered grid allows welders to configure the workspace instantly instead of re-measuring or improvising support points each time.

This time savings compounds especially in bulk supply production environments, where repetitive tasks demand consistent, streamlined setups.

3. Smooth Transition Between Multiple Projects

Because the table surface can be divided into functional zones, welders can prepare different components at the same time. Switching from one task to another doesn’t require tearing down the entire setup, which greatly boosts daily productivity.

Industries that benefit most from modular tables include:

·Machinery fabrication

·Structural steel assembly

·Automotive repairs

·Custom art and decorative metalwork

·Industrial maintenance

Safety and Comfort Are Built Into Modular Designs

Safety is fundamental in welding, and modular systems support safer operation through better control and stability.

4. Stronger Control Over Material Positioning

Materials can be secured from multiple angles, preventing them from slipping or shifting during welding. This not only reduces defects but also lowers the risk of injuries caused by sudden movement.

5. Configurable Height and Ergonomic Benefits

Many modular tables allow height adjustments or attachment of ergonomic accessories. Welders can adapt the table to their preferred working posture, which helps reduce fatigue during long shifts and boosts long-term productivity.

A Long-Term Investment That Reduces Overall Costs

A durable Welding Table is a foundational investment. Modular versions are engineered from high-strength steel and built to withstand repeated clamping, heat exposure, and structural load.

6. Built With Professional Manufacturer Precision

Tables constructed under strict manufacturer-grade production controls maintain flatness, resist warping, and preserve surface integrity even under heavy and continuous use. This reliability prevents the need for frequent replacements and minimizes rework caused by inaccurate surfaces.

Over years of operation, these features translate into significant cost savings.

Versatility: The Core Advantage of Modular Welding Tables

One of the most valuable benefits of modular systems is the ability to adapt quickly to different project requirements.

7. Broad Accessory Compatibility

Welders can integrate numerous tools—such as angle fixtures, clamps, support blocks, or alignment brackets—into the table surface. Accessories attach firmly into the grid layout, allowing for nearly limitless configurations that support both highly detailed and large-format work.

8. Perfect for Training, Education, and Skill Development

Training centers and vocational programs favor modular tables because instructors can quickly create new setups for different welding techniques. Students gain hands-on experience while working on authentic, real-world configurations.

How Modular Welding Tables Elevate Overall Workshop Operations

Here are the key transformations workshops experience after adopting modular systems:

·More accurate part alignment and measurement

·Faster project turnover through reduced setup time

·Greater safety and stability during welding

·Improved comfort and ergonomic customization

·Long-lasting durability under heavy workloads

·Broad compatibility with tools and fixtures

·Strong support for both specialized work and large-scale production

Conclusion: Modular Welding Tables Define the Future of Workshop Efficiency

From improved accuracy to accelerated workflows, modular systems show how essential a dependable Welding Table is to modern metal fabrication. When crafted through consistent production quality standards and available for stable bulk supply, these tables become a long-term asset that enhances performance across every stage of the welding process.

For any workshop striving to boost output, safety, and precision, investing in a modular design means equipping your team with a tool that supports consistent, professional results. In the end, high-quality welding always begins with the right Welding Table.

References

GB/T 7714:Suryanto A E, Lumbantobing M A, Murwantini S, et al. Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision[J]. G-Tech: Jurnal Teknologi Terapan, 2025, 9(1): 29-39.

MLA:Suryanto, Ahmad Eko, et al. "Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision." G-Tech: Jurnal Teknologi Terapan 9.1 (2025): 29-39.

APA:Suryanto, A. E., Lumbantobing, M. A., Murwantini, S., Samudra, A., & Supriyadi, S. (2025). Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision. G-Tech: Jurnal Teknologi Terapan, 9(1), 29-39.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province