News Detail

How to Maintain Welding Tables for Long-Term Durability

author:hxrtools Time:2025-09-14 11:27:11 Click:108

The Importance of a Welding Table

Every welder knows the value of a stable and precise welding table. It is the foundation for accurate joints, reliable clamping, and safe operation. Whether in a small workshop or a large-scale production plant, a table that is properly maintained performs better and lasts longer. And when the table is sourced from a Chinese manufacturer with verified bulk supply capability, correct upkeep ensures you get the most out of your investment.

What a Welding Table Really Does

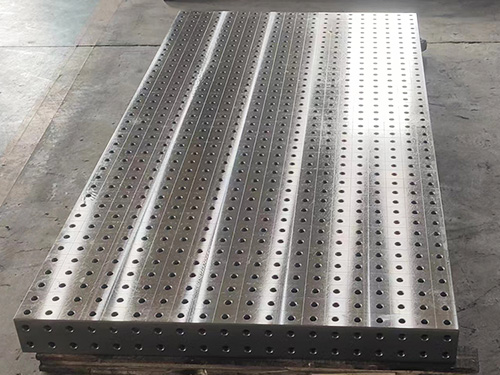

A welding table is not just a flat piece of steel. It is a carefully engineered base designed to resist heat, absorb impact, and remain flat despite constant exposure to sparks and spatter. The T-slots, holes, or grids allow fixtures and clamps to hold metal pieces securely, ensuring alignment and repeatability.

But even the strongest steel or cast-iron welding tables will deteriorate if they are not maintained. Surface damage, rust, or distortion can compromise both accuracy and safety.

Issues That Reduce Durability

1.Oxidation and Rust

Heat and humidity create the perfect environment for corrosion. A rusty surface interferes with both clamping and conductivity.

2.Surface Spatter

Weld spatter that is not removed promptly will harden on the surface, creating bumps that affect flatness.

3.Thermal Distortion

Without protective layers, concentrated heat in one area may slowly deform the table.

4.Wear of Fixtures

Clamps, bolts, and accessories loosen or wear down under heavy use.

Maintenance Strategies for Long Service Life

1. Clean After Each Job

Clear away debris, slag, and metal dust. Use brushes or scrapers designed for welding surfaces, avoiding aggressive grinding that may reduce accuracy.

2. Apply Protective Coatings

A thin layer of anti-rust oil or a protective spray prevents moisture damage. Covering the table during downtime adds another layer of defense.

3. Protect Against Heat and Spatter

Fire-resistant mats or shields reduce direct spatter impact, lowering the risk of burns and surface pitting.

4. Inspect for Flatness

Use precision tools to check the surface periodically. If deviations appear, professional re-machining can restore accuracy.

5. Maintain Fixtures and Accessories

Regular lubrication and tightening of clamps, bolts, and modular parts ensures reliability and consistent performance.

6. Control Storage Conditions

Keep the welding table in a dry, ventilated space. Avoid direct contact with damp floors to prevent long-term corrosion.

Why Maintenance Pays Off

Well-maintained welding tables bring multiple benefits:

·Extended Lifetime – Less frequent replacements lower costs.

·Consistent Accuracy – Essential for repeatable, high-quality welds.

·Safer Work Conditions – A flat, stable surface minimizes risks.

·Increased Productivity – Less downtime means more work completed.

Choosing a Welding Table Built to Last

Alongside maintenance, buying the right table in the first place is crucial. Points to evaluate include:

·Material Strength – Cast iron or heavy-duty steel provides better load capacity.

·Surface Finish – Precision-machined surfaces help keep alignment accurate.

·Size and Thickness – Match to your typical project requirements.

·Modular Flexibility – Slot systems and fixture holes allow versatile setups.

·Supplier Reliability – A China supplier with the ability to deliver bulk orders demonstrates true manufacturing strength and consistent quality.

Conclusion

The welding table is the backbone of precision welding, making proper upkeep essential. Regular cleaning, rust prevention, fixture maintenance, and inspection practices ensure long-term durability.

When combined with smart purchasing—choosing a table from a trusted Chinese manufacturer with bulk supply capacity—your welding table transforms into a long-term asset. By protecting this foundation, you safeguard both welding quality and workshop productivity.

References

GB/T 7714:Mayr J, Gebhardt M, Massow B B, et al. Cutting fluid influence on thermal behavior of 5-axis machine tools[J]. Procedia CIRP, 2014, 14: 395-400.

MLA:Mayr, Josef, et al. "Cutting fluid influence on thermal behavior of 5-axis machine tools." Procedia CIRP 14 (2014): 395-400.

APA:Mayr, J., Gebhardt, M., Massow, B. B., Weikert, S., & Wegener, K. (2014). Cutting fluid influence on thermal behavior of 5-axis machine tools. Procedia CIRP, 14, 395-400.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province