News Detail

How T-Slot Platforms Support Modern Workholding Innovation

author:hxrtools Time:2025-09-23 15:42:47 Click:199

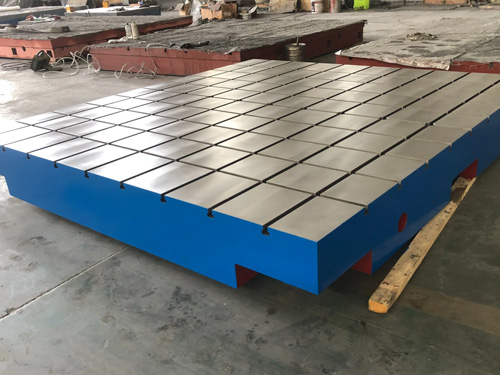

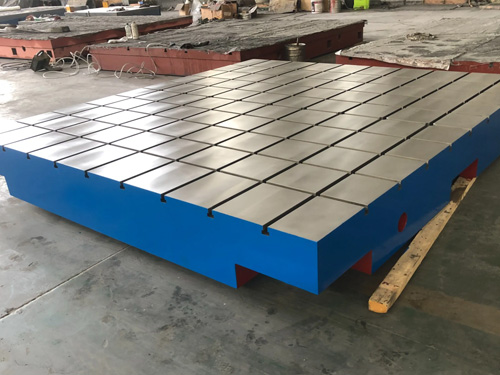

In the field of precision engineering, the T-slot Cast Iron Platform has established itself as a trusted foundation for diverse workholding setups. Its robust build, stable performance, and adaptability make it a key component in machining workshops, inspection rooms, and assembly facilities. For industries aiming to optimize efficiency, understanding how T-slot platforms facilitate advanced workholding is essential.

What Makes the T-Slot Design Unique?

The T-shaped grooves across the cast iron surface allow fixtures, clamps, and bolts to be quickly positioned and locked. This simple yet powerful design enables technicians to configure custom layouts for components of nearly any size or geometry.

Because of this flexibility, a T-slot Cast Iron Platform is not just a passive base—it actively enhances productivity by reducing reconfiguration times and ensuring accuracy under heavy-duty operations.

Core Benefits of T-Slot Cast Iron Platforms

1.Exceptional Stability

Cast iron inherently dampens vibrations, preventing errors during machining or inspection.

2.Flexible Workholding Options

Clamps and fixtures can be easily adjusted along the T-slots, allowing quick adaptation to new projects.

3.Built to Last

High wear resistance and dimensional stability ensure the platform remains accurate for years of intensive use.

4.Wide Compatibility

Standardized T-slots make it possible to integrate multiple jigs, clamps, and modular systems seamlessly.

Where T-Slot Platforms Are Commonly Used

·CNC and Conventional Machining: Holding heavy or irregular parts for milling, boring, and drilling.

·Metrology and Quality Control: Acting as a reference surface for measurement tools.

·Fabrication and Welding: Keeping workpieces stable during joining processes.

·Prototype Development: Allowing engineers to experiment with different fixture setups.

In each of these cases, the T-slot Cast Iron Platform proves its value as an enabler of precision and repeatability.

Importance of Reliable Sourcing

Not all T-slot platforms deliver the same level of accuracy. Inferior casting or poor machining can compromise flatness and reduce service life. For companies that require dependable performance, choosing a qualified manufacturer is critical.

In many cases, working directly with a China-based supplier that offers bulk production is the most efficient option. It guarantees consistent standards while meeting large-scale industrial demand at competitive prices.

Keeping Your T-Slot Platform in Top Condition

To ensure long service life, operators should follow a few simple practices:

·Clean regularly: Remove chips and dirt from grooves to avoid fixture misalignment.

·Protect against rust: Light oil or anti-corrosion spray should be applied periodically.

·Check accuracy: Flatness and slot alignment should be tested after extended use.

·Cover when idle: Prevent dust and moisture from affecting the cast iron surface.

By maintaining these routines, users extend the performance and precision of their T-slot Cast Iron Platform.

Looking Ahead: T-Slot Platforms in Advanced Manufacturing

With automation and robotics reshaping industries, modular and precise workholding bases are more important than ever. The T-slot Cast Iron Platform will remain vital not only for traditional machining but also for robotic assembly, automated inspection, and material testing.

For businesses scaling production, partnering with Chinese manufacturers that provide batch supply offers both affordability and reliability, ensuring long-term competitiveness.

Conclusion

From machining centers to inspection laboratories, the T-slot Cast Iron Platform continues to serve as an essential element of advanced workholding solutions. Its strength, adaptability, and precision make it a long-term investment for industries worldwide.

By sourcing directly from trusted China-based bulk supply manufacturers, companies can secure platforms that combine durability with cost efficiency—reinforcing the role of T-slot solutions as a cornerstone of modern industrial processes.

References

GB/T 7714:Newaz A A H, Jahan R. Design and Implementation of Fixtures for Milling, Shaping and Drilling Operations[J]. arXiv preprint arXiv:2503.06774, 2025.

MLA:Newaz, Abdullah Al Hossain, and Refat Jahan. "Design and Implementation of Fixtures for Milling, Shaping and Drilling Operations." arXiv preprint arXiv:2503.06774 (2025).

APA:Newaz, A. A. H., & Jahan, R. (2025). Design and Implementation of Fixtures for Milling, Shaping and Drilling Operations. arXiv preprint arXiv:2503.06774.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province