News Detail

Key Quality Checks Before Buying Cast Iron Platforms

author:hxrtools Time:2025-12-15 21:15:16 Click:95

Why Cast Iron Platforms Must Be Evaluated Carefully

A reliable Cast Iron Platform is indispensable in machining workshops, measurement labs, metal fabrication stations, equipment alignment tasks, and assembly lines. Because this platform often serves as the reference plane for precision work, even minor deformation can affect the accuracy of the entire production process.

Today many suppliers offer different levels of cast iron platforms, but only a true Production-oriented Manufacturer can ensure consistent flatness, material stability, and dimensional durability. To avoid quality issues, buyers should perform several critical checks before making a purchase.

1. Material Grade: The Core Determinant of Platform Stability

One of the strongest advantages of cast iron is its ability to damp vibration and maintain geometric stability under long-term loading. However, the material quality varies widely.

Buyers should confirm whether the platform is produced using high-grade cast iron such as HT250 or equivalent. This grade typically features excellent wear resistance and maintains a stable hardness range suitable for both precision measurement and heavy-duty support.

Additionally, you should verify that the platform has undergone proper chemical composition testing, ensuring the levels of carbon, silicon, and trace elements are within controlled limits. A trustworthy Cast Iron Platform Manufacturer will always provide these certifications.

2. Flatness Accuracy: The Most Critical Performance Indicator

No matter the size or application, the flatness of a cast iron platform determines its reliability. Precision inspection, CNC setup, and metrology tasks all rely on a surface that maintains the same height and level across its entire working area.

Before buying, request an official flatness test report performed with high-accuracy instruments such as laser measuring devices or granite reference equipment. The platform should also undergo either fine hand scraping or accurate CNC surface machining to achieve a stable, repeatable working plane.

Flatness accuracy must always be documented; relying on unverified claims is risky.

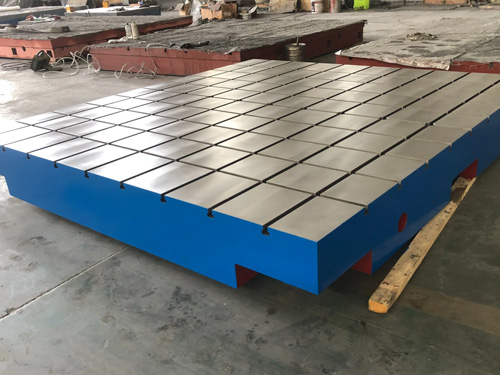

3. Internal Rib Structure: The Hidden Strength Behind Load Capacity

Users often focus on the surface finish but overlook the internal structural design. The rib pattern under the working surface determines how well the Cast Iron Platform resists bending, twisting, and long-term load deformation.

A well-designed rib structure includes evenly distributed reinforcements that allow the platform to maintain rigidity even when supporting heavy machinery or large workpieces. When evaluating a platform, check whether the Manufacturer provides casting drawings or cross-section images. These can reveal whether the internal structure is optimized or merely produced for low-cost mass shipment.

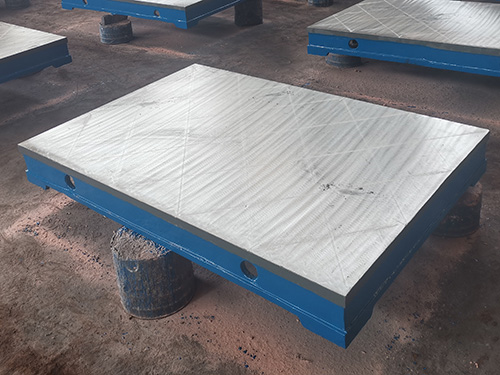

4. Surface Treatment Quality: A Sign of True Craftsmanship

The surface of a cast iron platform must not only be flat—it must also withstand repeated use without wearing prematurely.

High-quality platforms normally include:

·A uniform anti-rust coating

·Clean scraping marks or evenly machined surfaces

·Smooth and deburred edges

·No pits, pinholes, bumps, or visible machining errors

Imperfections on the surface often indicate poor casting quality or insufficient finishing. The workmanship visible on the top layer reflects the overall Production standards of the Manufacturer.

5. Stress Relief and Aging Treatment: Ensuring Long-Term Accuracy

Cast iron tends to hold internal stress after casting. Unless this stress is properly released, the platform may warp months or even years after purchase.

Buyers should verify whether the platform has undergone natural aging or artificial thermal aging. Both methods help stabilize the material and prevent dimensional drift. Any trustworthy Manufacturer will have documentation proving the platform was subjected to stress-relief processes before machining.

6. Load Requirements and Real-World Applications

Before purchasing, consider how the platform will be used. Different industrial environments require different performance characteristics.

For example:

·Precision labs need highly stable, low-deformation surfaces.

·Machine shops need platforms that can withstand constant loading and vibration.

·Assembly and welding areas require platforms resistant to heat and impact.

The Manufacturer should be able to specify the platform’s maximum load capacity, recommended support points, and safe usage scenarios. This information helps ensure long-term durability and prevents unexpected deformation.

7. Verifying Production Capability: Distinguishing Real Manufacturers from Resellers

To ensure product reliability, confirm that your supplier is a direct-production Cast Iron Platform Manufacturer, not a trading intermediary. Manufacturers with real Production strength typically have:

·Their own casting workshops

·CNC machining equipment

·Skilled scraping technicians

·Inspection tools for flatness testing

·Documented quality management systems

A professional Manufacturer will always supply testing reports, quality certificates, and material inspection documents—critical signs that the product meets industrial standards.

8. Customization Options for Specialized Applications

Many industries require platforms with specific features. Whether you need threaded inserts, T-slots, mounting holes, special dimensions, or modular combinations, a real Manufacturer should offer tailor-made solutions.

Customization often includes:

·Adjusted surface accuracy

·Reinforced legs or frames

·Enhanced rib patterns for higher load

·Additional machining for assembly fixtures

These options allow buyers to match the platform to their workflow and maximize efficiency.

Conclusion: Choose a Precision-Verified Cast Iron Platform from a True Manufacturer

A Cast Iron Platform is more than a support surface—it is the foundation for accuracy in machining, inspection, equipment setup, and industrial alignment. Before purchasing, always verify material quality, flatness accuracy, rib structure, surface finish, stress-relief history, and most importantly, the Production capabilities of the Manufacturer.

A carefully selected platform ensures high performance, long-term stability, and consistent precision across your entire industrial process.

References

GB/T 7714:Groover M P. Fundamentals of modern manufacturing: materials, processes, and systems[M]. John Wiley & Sons, 2010.

MLA:Groover, Mikell P. Fundamentals of modern manufacturing: materials, processes, and systems. John Wiley & Sons, 2010.

APA:Groover, M. P. (2010). Fundamentals of modern manufacturing: materials, processes, and systems. John Wiley & Sons.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province