News Detail

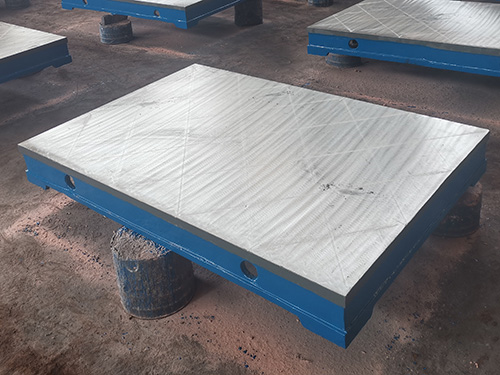

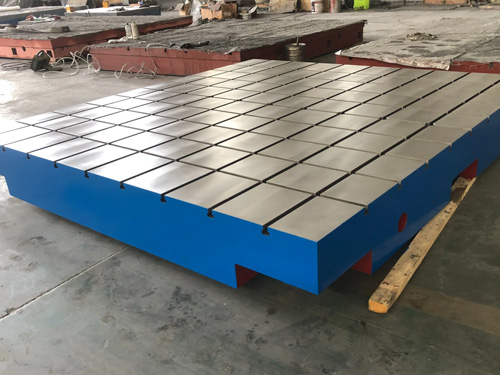

Maximizing Fixturing Efficiency with T-Slot Cast Iron Platforms

author:hxrtools Time:2025-10-21 17:04:04 Click:129

In modern machining and fabrication, a T-slot Cast Iron Platform is more than just a working surface—it serves as the foundation for precision, stability, and operational flexibility. From CNC milling to assembly and welding, the right platform ensures workpieces are held securely, allowing for consistent, high-quality results. This guide provides practical tips for optimizing fixturing with T-slot cast iron platforms while exploring the benefits of sourcing from reliable China manufacturers with bulk supply options.

What Makes T-Slot Cast Iron Platforms Essential

A T-slot cast iron platform is specifically designed for heavy-duty fixturing. Its unique characteristics make it indispensable for high-precision tasks:

·Superior rigidity and flatness – minimizes vibration and maintains dimensional accuracy.

·T-slot grooves – allow flexible placement of clamps, bolts, and fixtures.

·Durable cast iron construction – provides long-lasting wear resistance and stability under heavy loads.

With these features, T-slot platforms are ideal for workshops seeking repeatable and reliable setups.

Key Advantages of T-Slot Cast Iron Platforms

Precision and Accuracy

The inherent rigidity of cast iron significantly reduces deflection during operations, ensuring superior machining accuracy. T-slot grooves facilitate precise fixture placement, enabling consistent positioning of workpieces across multiple setups.

Flexibility in Fixturing

T-slot platforms offer unmatched versatility. Clamps and fixture blocks can be repositioned quickly, accommodating a variety of workpiece sizes and shapes without compromising stability. This flexibility is critical for dynamic workshops handling diverse projects.

Stability and Safety

The substantial weight of cast iron provides a stable base, reducing vibrations that can affect tool life and workpiece quality. A stable platform also enhances operator safety, particularly in heavy machining or welding environments.

Optimizing Fixturing Techniques

To leverage a T-slot cast iron platform effectively, consider the following best practices:

1.Use modular fixturing components – Combine T-slot bolts, clamps, and fixture blocks for adaptable setups.

2.Plan setups in advance – Strategically place clamps and bolts to minimize adjustments during operations.

3.Monitor flatness regularly – Ensure the platform remains level to maintain precision.

4.Distribute weight evenly – Avoid concentrating heavy components in a single area to prevent deformation.

Applying these techniques will enhance workflow efficiency and maximize machining quality.

Why Choose China Manufacturers

China has emerged as a major source for T-slot cast iron platforms, offering cost-effective solutions without compromising quality. Key advantages include:

·Factory-direct bulk supply – Many China suppliers can provide batch orders directly from the factory, ideal for workshops and industrial buyers seeking competitive pricing.

·Customization options – Platforms can be tailored for specific T-slot spacing, thickness, or surface finishes.

·Quality and precision – Reputable Chinese manufacturers maintain high flatness, surface smoothness, and durability standards, meeting international machining requirements.

Partnering with a trusted China manufacturer ensures access to reliable T-slot cast iron platforms and scalable production for large projects.

Maintenance Tips for Longevity

Proper maintenance preserves platform integrity and ensures consistent performance:

·Keep surfaces clean – Remove metal chips, dust, and debris after each use.

·Prevent rust – Apply light oil or anti-corrosion spray to protect the cast iron surface.

·Avoid localized overload – Spread heavy workpieces evenly to maintain flatness.

·Inspect periodically – Check T-slot condition and platform level for optimal performance.

Routine maintenance prolongs the lifespan of your T-slot cast iron platform and keeps fixturing operations precise and safe.

Selecting the Right Supplier

When sourcing a T-slot cast iron platform, consider these factors:

·Manufacturer credibility – Look for China suppliers with a proven record of batch supply.

·Customizability – Ensure they can produce platforms with the T-slot configuration suited to your workflow.

·Certifications – ISO or equivalent standards indicate reliable quality.

·Efficient logistics – Timely shipping is essential for large or bulk orders.

Choosing the right supplier guarantees both product quality and reliable delivery for your workshop.

Conclusion

A T-slot Cast Iron Platform is a cornerstone for precise, durable, and flexible fixturing in modern machining. By implementing optimized fixturing techniques, maintaining platform integrity, and sourcing from trustworthy China manufacturers with factory-direct batch supply, workshops can achieve higher accuracy, efficiency, and long-term reliability.

Investing in a high-quality T-slot cast iron platform ensures repeatable setups, superior machining results, and a stable foundation for all fixturing applications.

References

GB/T 7714:JASH Metrology. (2025). T-Slotted Floor / Bed Plates / Base Plates.

MLA:JASH Metrology. "T-Slotted Floor / Bed Plates / Base Plates." JASH Metrology, 2025.

APA:JASH Metrology. (2025). T-Slotted Floor / Bed Plates / Base Plates.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province