News Detail

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

author:hxrtools Time:2025-11-21 12:25:54 Click:79

As a China modular welding table manufacturer and bulk supplier, we know that the foundation of every high-quality weld begins with a stable and precisely leveled workspace.

In modern metal fabrication, accuracy and repeatability are essential — and modular welding tables have become the industry’s preferred solution for achieving both.

Engineered with flexibility and durability in mind, modular welding tables allow fabricators to complete complex projects with greater efficiency, less setup time, and consistent accuracy.

Let’s explore how these tables are redefining the standards of welding and assembly across industries.

1. Understanding Modular Welding Tables

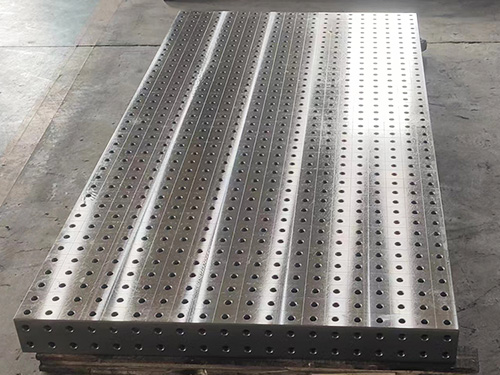

A modular welding table is a precision-engineered work surface featuring a grid of uniformly spaced holes and slots.

This structure allows for quick setup of clamps, fixtures, and supports — ideal for holding components securely during welding or assembly.

Unlike conventional solid platforms, modular designs can be expanded, reconfigured, and customized to accommodate different workpiece sizes and shapes.

Most tables are made from high-strength alloy steel or cast iron, treated through nitriding, oxidation, or anti-rust coating for enhanced hardness and corrosion protection.

2. Why Modular Welding Tables Are Essential

(1) Consistent Accuracy and Repeatability

Precision is at the heart of fabrication.

A high-quality modular welding table offers flatness accuracy within 0.02 mm per meter, allowing welders to achieve consistent, repeatable setups every time.

With accurately machined grid holes, fixtures can be repositioned instantly for identical assemblies — an advantage that saves hours in batch production or serial manufacturing.

(2) Ultimate Flexibility in Setup

One of the most remarkable advantages of modular tables is their modular expandability.

Multiple tables can be joined seamlessly, forming large workstations or specialized layouts.

Accessories such as positioning blocks, clamping angles, and locator pins enable infinite combinations, adapting easily to any component geometry — from light sheet-metal parts to heavy industrial frames.

(3) Improved Efficiency and Workflow

Traditional welding setups often require constant measuring, alignment, and adjustment.

With a modular system, operators can assemble precise fixtures in minutes without needing specialized tools.

This streamlined workflow minimizes downtime, reduces rework, and accelerates production — turning precision into profitability.

(4) Ergonomics and Safety

Beyond accuracy, modular welding tables are designed for better ergonomics and safety.

The adjustable height and customizable layout help welders maintain a comfortable working posture, minimizing fatigue and preventing alignment errors.

Additionally, the table’s anti-slip surface and rigid clamping system reduce the risk of part movement, improving both operator safety and product quality.

3. Surface Treatments and Durability

A key indicator of modular table quality lies in its surface treatment.

Professional China manufacturers apply multiple finishing processes to ensure lasting precision and protection:

·Stress relief annealing to remove internal tension from casting or welding.

·Fine grinding and machining for mirror-flat surfaces.

·Nitriding or oxidation to improve hardness and corrosion resistance.

·Protective oiling or painting for shipping and long-term storage.

These steps guarantee that every modular welding table maintains its geometry and smooth operation even under heavy loads and high temperatures.

4. Industrial Applications

Thanks to their accuracy and adaptability, modular welding tables are used across a wide range of industries:

·Automotive and transportation — for frame, exhaust, and chassis alignment.

·Aerospace fabrication — where precise positioning is critical.

·Heavy equipment manufacturing — for assembling large or irregular structures.

·Architectural and artistic metalwork — where design precision meets creativity.

Their modular nature allows workshops to scale production easily, from single prototypes to bulk assembly operations.

5. How to Choose the Right Modular Welding Table

When sourcing or purchasing a modular welding table, it’s essential to assess several technical and functional factors:

·Material composition: Choose cast iron for vibration resistance or alloy steel for strength.

·Flatness tolerance: Higher precision ensures long-term reliability.

·Hole and slot grid: Common standards include 16 mm, 22 mm, or 28 mm spacing.

·Surface treatment: Look for nitriding or oxide finishes for durability.

·Load capacity: Ensure the table supports your heaviest components.

·Accessory compatibility: Confirm system compatibility for clamps and fixtures.

Collaborating directly with a China modular welding table factory ensures better quality control, OEM customization, and cost efficiency for bulk production.

6. Maintenance for Longevity

Even with premium construction, maintenance plays a vital role in extending the table’s lifespan:

·Clean the surface after every project to remove residue.

·Apply a thin layer of anti-rust oil regularly.

·Store accessories and clamps in a dry, organized environment.

·Inspect flatness annually to maintain precision performance.

Proper maintenance ensures your modular welding table remains a dependable partner in fabrication for years.

7. Conclusion

A modular welding table is more than a workbench — it’s a precision foundation that defines the quality of every weld.

Its flexibility, accuracy, and stability make it indispensable in modern metal fabrication.

As a China manufacturer specializing in bulk modular welding table supply, we continue to innovate surface treatments, clamping systems, and modular configurations that align with global quality standards.

Whether you’re building high-precision machinery or custom metal structures, investing in a reliable modular system ensures consistent accuracy, higher productivity, and long-term efficiency.

In today’s competitive fabrication industry, the modular welding table stands as a symbol of innovation — bridging craftsmanship with modern engineering precision.

References

GB/T 7714:Hajduk M, Semjon J, Vagaš M. Design of the welding fixture for the robotic stations for spot welding based on the modular concept[J]. Acta Mechanica Slovaca, 2009, 13(3): 30-37.

MLA:Hajduk, Mikuláš, Ján Semjon, and Marek Vagaš. "Design of the welding fixture for the robotic stations for spot welding based on the modular concept." Acta Mechanica Slovaca 13.3 (2009): 30-37.

APA:Hajduk, M., Semjon, J., & Vagaš, M. (2009). Design of the welding fixture for the robotic stations for spot welding based on the modular concept. Acta Mechanica Slovaca, 13(3), 30-37.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province