News Detail

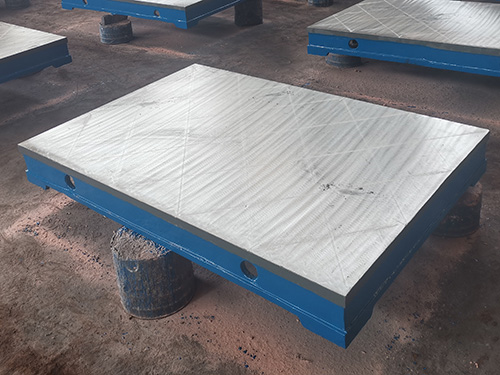

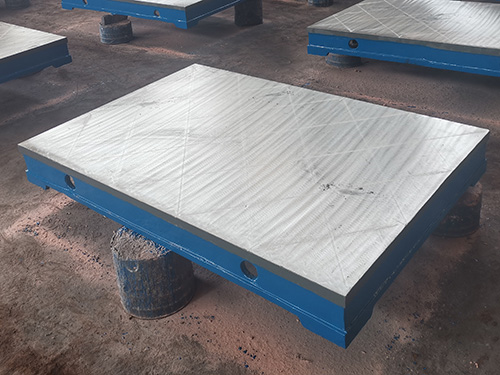

The Role of Cast Iron Platforms in Industrial Automation

author:hxrtools Time:2025-09-17 12:04:26 Click:179

Cast Iron Platforms as the Foundation

In the fast-paced world of modern industry, automation systems demand absolute stability and precision. At the center of this reliability stands the Cast Iron Platform. Serving as the foundation for robotic cells, CNC machines, and automated measuring setups, it provides the flatness, rigidity, and load capacity required for flawless operations.

When sourcing equipment, many companies rely on a Chinese manufacturer with proven bulk supply capacity to ensure consistent quality and affordability, especially for high-volume production lines.

Why Cast Iron Platforms Are Essential in Automation

1. Accuracy That Lasts

Automated processes depend on repeatability. A cast iron platform offers a machined surface with precise tolerances, preventing misalignments that could disrupt robotics or inspection systems.

2. Natural Vibration Damping

Automation involves continuous motion, cutting, or welding. Cast iron absorbs vibrations more effectively than many alternatives, protecting the accuracy of sensors and robotic arms.

3. Strength for Heavy Loads

Industrial operations often involve oversized or weighty parts. A cast iron platform provides the strength to support these loads without losing flatness or structural integrity.

4. Flexible Configurations

Thanks to integrated T-slots and fixture points, cast iron platforms allow engineers to quickly adjust setups for new projects, making them well-suited for flexible and smart manufacturing.

Key Applications in Industrial Automation

·Robotic Systems – Secure, vibration-free bases for welding, handling, and assembly robots.

·Machining Operations – Stable surfaces for CNC machines and automated milling centers.

·Precision Inspection – Reliable measurement bases in automated metrology labs.

·Fabrication Lines – Structural support for automated welding or heavy-duty assembly.

How to Extend the Service Life of Cast Iron Platforms

Even though cast iron is robust, preventive care maximizes its lifespan:

1.Daily Cleaning – Remove metal chips, spatter, and dust before they accumulate.

2.Rust Prevention – Light oiling or protective coatings reduce corrosion risks.

3.Regular Calibration – Checking surface flatness ensures accuracy over time.

4.Controlled Storage – Keep platforms in dry, ventilated conditions to avoid damage from humidity.

Why Cast Iron Surpasses Other Materials

While steel or polymer composites sometimes appear in industrial applications, cast iron continues to dominate for several reasons:

·Superior vibration damping – Keeps machines stable and precise.

·Longevity – Capable of performing for decades under heavy loads.

·Restorable surface – Precision can be renewed through re-machining.

These features explain why cast iron remains the standard choice for automation platforms worldwide.

Selecting the Right Supplier

The long-term performance of an automation line doesn’t only depend on equipment design—it also depends on supplier reliability. Partnering with a China supplier that can handle bulk orders ensures stable pricing, consistent quality, and reliable delivery. This is especially important for factories expanding automation capabilities at scale.

Conclusion

The Cast Iron Platform is more than just a base—it is the silent enabler of industrial automation. By delivering stability, load capacity, and vibration control, it guarantees that automated systems can perform with accuracy and efficiency.

Through proper care and by working with trusted Chinese manufacturers offering bulk supply, businesses can secure platforms that last for years while supporting demanding automation tasks. In the race toward smarter, more precise production, the cast iron platform remains a cornerstone of reliability.

References

GB/T 7714:Aggogeri F, Borboni A, Merlo A, et al. Vibration damping analysis of lightweight structures in machine tools[J]. Materials, 2017, 10(3): 297.

MLA:Aggogeri, Francesco, et al. "Vibration damping analysis of lightweight structures in machine tools." Materials 10.3 (2017): 297.

APA:Aggogeri, F., Borboni, A., Merlo, A., Pellegrini, N., & Ricatto, R. (2017). Vibration damping analysis of lightweight structures in machine tools. Materials, 10(3), 297.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province