News Detail

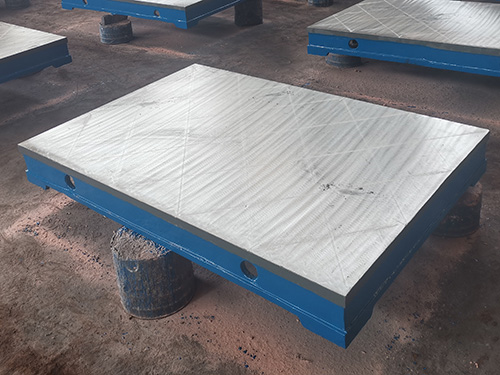

Trusted Cast Iron Surface Plate Exporter from China: Quality Meets Precision

author:hxrtools Time:2025-12-28 12:42:06 Click:98

Selecting a dependable Cast iron surface plate exporter is essential for industries where measurement accuracy and structural stability cannot be compromised. Across workshops, quality laboratories, machining centers, and heavy industrial environments, cast iron surface plates remain the backbone of precise inspection and calibration. China has earned a leading position in this field by combining strict material control with modern manufacturer-grade production systems capable of supporting global bulk supply requirements.

How Cast Iron Surface Plates Support Precision Workflows

The primary purpose of a cast iron surface plate is to provide a stable, flat, vibration-resistant platform that enables precision measurement and machine setup. Whether it’s used for tool calibration, layout marking, part inspection, or metrology testing, its performance directly influences the reliability of the entire workflow. This is why choosing the right exporter—one that understands industrial accuracy—is as important as the plate itself.

Material Integrity: The Foundation of Reliable Surface Plates

A major factor distinguishing Chinese exporters is the use of high-quality gray cast iron with superior damping characteristics. The combination of pearlitic structure, controlled hardness, and uniform casting processes ensures:

·minimal distortion over time

·strong resistance to wear

·excellent vibration absorption

·steady performance under heavy workloads

When produced by a genuine manufacturer, the material goes through thermal stabilization cycles and stress-relief treatments that help maintain long-term precision.

Production Technology Behind Accurate Surface Plates

Precision flatness does not happen by accident—it is engineered. Modern exporters rely on advanced Production systems such as:

·CNC-controlled grinding machines

·semi-automated scraping tools

·multi-point accuracy inspection equipment

·calibrated granite reference platforms

These tools allow the exporter to achieve high-accuracy grades in line with international measurement standards. For industries that require Grade 0 or Grade 1 flatness, this level of Production technology is critical.

Design, Structure, and Load Performance

The internal rib structure beneath a cast iron surface plate plays a significant role in its durability. Structural engineering of the ribs enhances:

·resistance to bending

·improved load distribution

·reduced vibration

·increased long-term stability

For customers who rely on these plates for heavy components, assembly setups, or precise tooling operations, the exporter’s ability to design strong internal ribbing is a major advantage—especially when customization is needed.

Why Global Buyers Prefer Chinese Exporters

1. Stable Quality at Competitive Prices

China’s mature casting industry allows exporters to combine strong performance with cost efficiency.

2. Manufacturer-Level Production Capacity

A trusted exporter typically operates as a direct manufacturer, handling casting, machining, inspection, coating, and packaging under one system. This integrated Production structure ensures consistent output and supports global bulk supply orders.

3. Professional Export Experience

From anti-corrosion painting to shock-resistant packaging, experienced exporters ensure that plates remain intact during long-distance international shipment.

4. Flexible Customization Options

Global buyers can request special features such as:

·T-slots

·inserts

·threaded holes

·lifting points

·anti-rust coatings

A mature exporter can incorporate these elements while maintaining precision.

Industries That Rely on Cast Iron Surface Plates

Because of their reliability and longevity, cast iron surface plates are widely used in:

·metrology and testing laboratories

·CNC machining and tool calibration

·automotive assembly and inspection

·aerospace component measurement

·metal fabrication and weld inspection

·mold and die manufacturing

As industrial development accelerates worldwide, the need for trustworthy exporters continues to increase.

The Future of Surface Plate Exporting

Industry demands are evolving toward smarter measurement systems, new-generation cast materials, and more efficient Production lines. Exporters equipped with digital inspection tools, automated machining processes, and stronger Manufacturing capabilities will lead the market in the next decade.

Conclusion: Precision Begins with the Right Exporter

From the selection of raw materials to the final inspection stage, every step affects the accuracy and durability of a cast iron surface plate. Choosing a reliable Cast iron surface plate exporter—preferably one with true manufacturer-level Production advantages—ensures long-term stability and precision for industrial operations. With China's engineering expertise, advanced technology, and strong bulk supply capabilities, global buyers continue to place their trust in these exporters for consistent and dependable cast iron measuring equipment.

A precise tool begins with a precise supplier—your project deserves nothing less.

References

GB/T 7714:Campbell J. Complete casting handbook: metal casting processes, metallurgy, techniques and design[M]. Butterworth-Heinemann, 2015.

MLA:Campbell, John. Complete casting handbook: metal casting processes, metallurgy, techniques and design. Butterworth-Heinemann, 2015.

APA:Campbell, J. (2015). Complete casting handbook: metal casting processes, metallurgy, techniques and design. Butterworth-Heinemann.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province