News Detail

Unlocking Machining Versatility with T-Slot Design

author:hxrtools Time:2025-11-09 08:10:57 Click:152

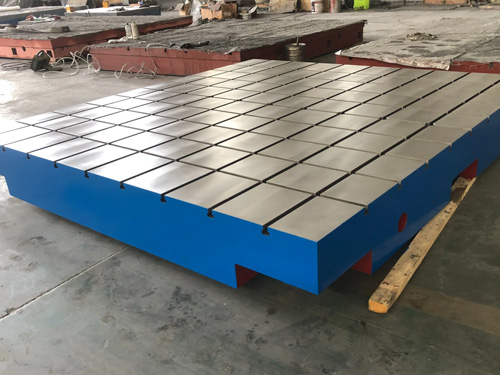

Every machining operation starts with one critical element — a stable and adaptable working surface. Among the many table configurations available, the T-slot cast iron platform stands out for its exceptional strength, accuracy, and flexibility.

Whether used in milling, inspection, or assembly, the T-slot design provides machinists with a foundation that supports quick fixture changes, secure workholding, and reliable precision. For workshops seeking cost-effective yet professional-grade solutions, platforms from a China supplier or China manufacturer with bulk supply capability offer unmatched value and durability.

1. Understanding the T-Slot Design Concept

A T-slot is a specially shaped groove, resembling an upside-down “T,” machined into the surface of a cast iron platform. This design allows bolts, nuts, and clamps to slide freely along the slot, giving operators the flexibility to fix workpieces or equipment in countless configurations.

When integrated into a cast iron platform, T-slots transform a simple surface into a multifunctional workspace. The material’s natural damping properties absorb vibration and minimize deflection during heavy machining, ensuring dimensional stability even in demanding environments.

2. The Role of T-Slot Design in Enhancing Versatility

The genius of the T-slot system lies in its ability to adapt to various machining tasks. It doesn’t just hold components—it transforms how efficiently operators can perform them.

a. Adjustable Workholding for Any Shape

T-slots enable the use of different clamps and fixtures, allowing machinists to secure irregular parts easily. Whether you’re machining small precision components or large castings, the slots allow rapid repositioning without permanent modifications.

b. Faster Setup and Operation

Instead of using fixed holes or custom jigs, T-slot hardware can be repositioned in seconds. This reduces downtime during setup and boosts productivity in both manual and CNC machining operations.

c. Stability and Accuracy

The T-slot cast iron platform offers a rigid, vibration-resistant base. Cast iron’s high density and structural uniformity minimize tool chatter, improve cutting accuracy, and extend tool life—crucial for tight-tolerance work.

d. Modular and Scalable Design

Because T-slots follow standardized dimensions, they integrate easily with automation systems, rotary tables, or modular fixturing. This modularity allows engineers to scale setups for different product sizes or production volumes effortlessly.

3. Why Cast Iron Is the Ideal Platform Material

Not all materials perform equally under machining stress. Cast iron remains the benchmark for T-slot tables due to its unique combination of strength and damping characteristics.

·Superior Vibration Control: Its microstructure absorbs vibration better than steel or aluminum, resulting in smoother finishes and more precise measurements.

·High Load Capacity: Supports heavy machines and fixtures without deformation.

·Stable Under Temperature Changes: Maintains flatness and dimensional accuracy during long operating cycles.

·Low Maintenance: Resistant to wear, corrosion, and mechanical stress with minimal care.

For these reasons, a T-slot cast iron platform serves as the foundation of any precision machining or inspection setup.

4. The Benefits of Working with a China Manufacturer

Today, many workshops around the world source T-slot cast iron platforms from experienced China suppliers. Here’s why:

·Factory-Level Bulk Supply: China manufacturers equipped with advanced foundry and CNC machining facilities can handle large-scale production while ensuring consistency in every piece.

·Cost Efficiency: Direct sourcing from the factory eliminates middlemen, offering competitive pricing without compromising quality.

·Customization Service: OEM and ODM options allow modification of slot width, spacing, or surface finish to meet specific engineering requirements.

·Comprehensive Quality Testing: From surface flatness checks to hardness inspection, strict QC standards guarantee long-term reliability.

Partnering with a China manufacturer offering bulk T-slot cast iron platform supply ensures a balance of precision, performance, and affordability — ideal for both domestic and global markets.

5. Applications Across Industries

Because of its adaptability, the T-slot design is used in almost every industrial field, such as:

·Metalworking & Fabrication: For holding parts during cutting, milling, or drilling.

·Inspection & Calibration: The flat and stable surface supports gauges and coordinate measuring instruments.

·Tool Assembly & Maintenance: Enables secure positioning of fixtures or tools during repair and testing.

·Automation Systems: Serves as a mounting base for robots or modular automation lines.

Its flexibility allows manufacturers to standardize fixtures across departments, reducing cost and improving production efficiency.

6. Maintenance Practices for Long-Term Accuracy

Proper care ensures your T-slot table remains reliable for years of use:

Keep the surface and slots free from chips, dust, and coolant residues.

Apply a thin layer of protective oil after cleaning to prevent oxidation.

Avoid direct impact or over-tightening clamps, which could deform the slots.

Calibrate and inspect surface flatness periodically to maintain accuracy.

By following these simple practices, you preserve the integrity of your T-slot cast iron platform and guarantee consistent machining performance.

Conclusion: The T-Slot Cast Iron Platform — Foundation of Precision and Flexibility

In modern machining, flexibility and precision go hand in hand. The T-slot design provides the perfect solution for quick setup, stable clamping, and accurate alignment—key factors for efficient production.

For workshops or factories seeking dependable quality and scalable supply, partnering with a China manufacturer capable of bulk T-slot cast iron platform production ensures consistent results and lasting value.

A strong foundation makes all the difference—and that foundation begins with a well-crafted T-slot platform built for precision, strength, and adaptability.

References

GB/T 7714:Möhring H C, Biermann D, Bleicher F, et al. Fixtures and workpiece clamping systems in machining[J]. CIRP Annals, 2025.

MLA:Möhring, Hans-Christian, et al. "Fixtures and workpiece clamping systems in machining." CIRP Annals (2025).

APA:Möhring, H. C., Biermann, D., Bleicher, F., Melkote, S., & Kappmeyer, G. (2025). Fixtures and workpiece clamping systems in machining. CIRP Annals.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province