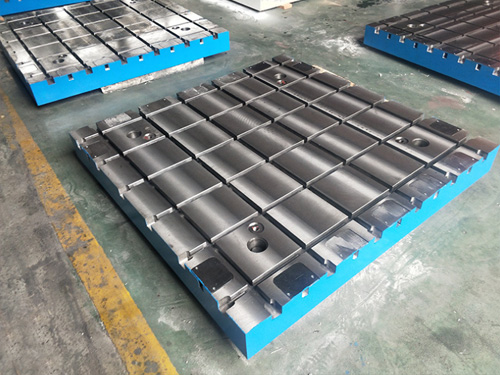

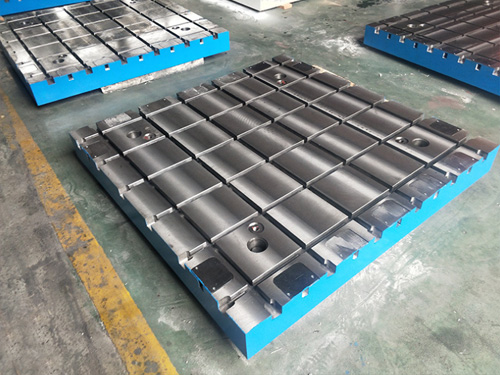

Product Details

Cast Iron Castings

Cast Iron Castings are plane reference tools used for workpiece detection or marking.The working surface of iron castings shall be free from casting defects such as sand holes,pores,cracks,slag inclusions and shrinkage porosity.The five elements in cast iron refer to carbon,silicon,manganese,sulfur and phosphorus.

1.Indicator measurement method:

The measuring device with indicator or coordinate measuring instrument measures the deviation value of the measured surface relative to the measurement base plane,and when checking the flatness error,adjust the corner points of the two diagonals to equal height or roughly equal height(or adjust any three distant points),move the measuring device point by point according to the corresponding point distribution form,record the indicator value Hi,and then the coordinate value of each measuring point relative to the measurement base plane can be obtained.This method is suitable for flatness error verification of medium and small cast iron test bench.

2.Ruler measurement method:

This method uses a ruler,dial indicator and gauge block(or contour block)to measure.Support the contour block at 2/9l(l-the length of the ruler)from both ends of the ruler,measure according to the specified section and measuring points,or plug the gauge block instead of the dial indicator to measure,so as to obtain the line deviation between the inspected point and the two ends,conduct data processing,and obtain the flatness value.This method is suitable for flatness verification of low accuracy inspection platform.

3.Knife edge ruler measuring method optical gap method:

This method takes the knife edge ruler as the benchmark and uses the optical gap method to measure.During verification,place the knife edge ruler on several sections of the tested cast iron workbench,observe the size of the optical gap,and compare it with the standard optical gap,determine the error value,and take the critical value as the flatness error value.

4.Padding method:

Two gauge blocks with the same size are set at both ends of the section of the inspected cast iron workbench,and the knife edge ruler is placed on the gauge block.The difference between the gauge block or feeler gauge inserted at the inspected point on the section and the gauge block with the same size at both ends is the deviation of the inspected point from the connecting line between the two ends,and then the data is processed to obtain the flatness error value.This method is suitable for flatness verification of low accuracy test platform.

When drawing up the technological process of cast iron test-bed plate,due to the different production types of cast iron test-bed plate,the processing methods,machine tools and equipment,clamping and measuring tools,cast iron test-bed plate blank and the technical requirements for workers are very different.In order to process a qualified cast iron test bench plate,the thickness of the metal layer cut from the cast iron test bench plate blank is called machining allowance.Machining allowance can be divided into process allowance and total allowance.The thickness of the metal layer to be cut in a process is called the machining allowance of the process.The total margin to be removed from the cast iron test bench slab blank to the finished product is called the total margin,which is equal to the sum of the process margins of the corresponding surface.

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province