Product Details

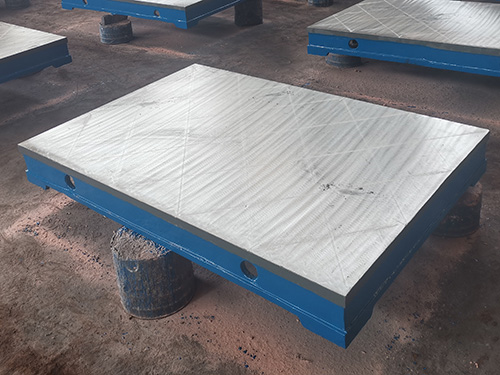

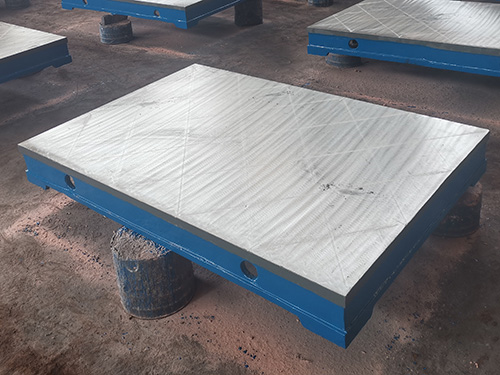

Cast Iron Platform

A cast iron platform,also known as a cast iron surface plate,is a fundamental tool in various industrial and metrological applications.Here is a detailed introduction:

Characteristics

High flatness:Through precise casting and machining processes,cast iron platforms can achieve a high level of flatness,with surface flatness errors typically within a very small range,which can meet the needs of high-precision measurement and processing.

Good stability:Cast iron has excellent rigidity and stability.It can maintain its shape and dimensional accuracy over a long period,is not easily affected by external forces and environmental factors,and can provide a reliable reference plane for measurement and processing.

Strong wear-resistance:Cast iron materials have relatively high hardness and wear-resistance.The surface of the platform is not easily scratched or worn,even after long-term use,which can maintain good surface quality and measurement accuracy.

Good damping performance:Cast iron has good damping characteristics,which can effectively absorb vibration and impact during the measurement and processing process,reduce the influence of vibration on the accuracy of the workpiece,and is conducive to improving the quality of measurement and processing.

Specifications and accuracy

Specifications:Cast iron platforms come in a variety of specifications and sizes.The common sizes include lengths ranging from 300mm to 2000mm and widths from 200mm to 1500mm.The thickness also varies according to different usage requirements.Larger-sized platforms are usually used in large-scale mechanical processing and assembly workshops,while smaller-sized platforms are suitable for laboratories and small-batch production occasions.

Accuracy levels:They are generally divided into levels 00,0,1,2,etc.Level 00 is the highest accuracy level,with extremely low flatness error and high-precision requirements,which is often used in aerospace,precision instrument manufacturing and other fields.Level 0 and level 1 accuracy are suitable for general precision mechanical processing and measurement,such as in the manufacturing of machine tools,molds,etc.Level 2 accuracy is relatively lower and is used in some occasions with lower accuracy requirements.

Applications

Measurement and inspection:It is used as a reference plane for measuring the size,shape and position of workpieces.For example,when measuring the flatness,parallelism and perpendicularity of workpieces,the cast iron platform provides a stable and accurate base,which can improve the accuracy and reliability of measurement results.

Machining and assembly:In the process of mechanical processing and assembly,the cast iron platform is used to place workpieces and fixtures to ensure the accuracy of workpiece installation and processing.It can also be used for the assembly and debugging of mechanical equipment to ensure the installation accuracy and assembly quality of each component.

Calibration of measuring tools:It is an important tool for calibrating measuring tools such as rulers,calipers and dial indicators.By comparing with the surface of the cast iron platform,the accuracy of measuring tools can be checked and corrected to ensure the accuracy of measuring tools.

Use and maintenance

Use methods

Installation and leveling:Before use,the cast iron platform should be installed on a stable foundation and leveled to ensure that its surface is horizontal.This can be achieved by using leveling feet and a spirit level to adjust until the platform reaches the required level of flatness.

Cleaning the surface:The surface of the platform should be kept clean before and after use.Remove dust,oil stains and other impurities with a clean cloth to avoid affecting the measurement accuracy and the surface quality of the workpiece.

Proper use:When using,avoid placing heavy and sharp-edged objects directly on the platform to prevent scratching and deforming the surface of the platform.When measuring,the measuring tools should be used correctly and gently to avoid colliding with the platform.

Maintenance points

Regular cleaning:Regularly clean the surface of the cast iron platform with a mild detergent and a soft cloth,and then dry it to prevent rust and corrosion.

Preventing rust:Apply an appropriate amount of anti-rust oil on the surface of the platform to prevent rusting.Especially in a humid environment,rust-prevention measures should be strengthened.

Periodic inspection and calibration:The cast iron platform should be inspected and calibrated regularly to check its flatness and accuracy.The calibration cycle is generally determined according to the frequency of use and accuracy requirements,usually once a year or half a year.If the accuracy deviation is found to be out of the allowable range,it should be repaired or calibrated in time.

HOT NEWS

HOT NEWS

-

Essential Guidelines for Caring for T-Slot Cast Iron Platforms

2025-09-30 03:39:57

-

How to Inspect and Calibrate a Granite Platform with Precision

2025-09-27 01:05:45

-

How T-Slot Platforms Support Modern Workholding Innovation

2025-09-23 03:42:47

-

Benefits of Granite Platforms in Precision Engineering

2025-09-20 12:57:20

-

The Role of Cast Iron Platforms in Industrial Automation

2025-09-17 12:04:26

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province