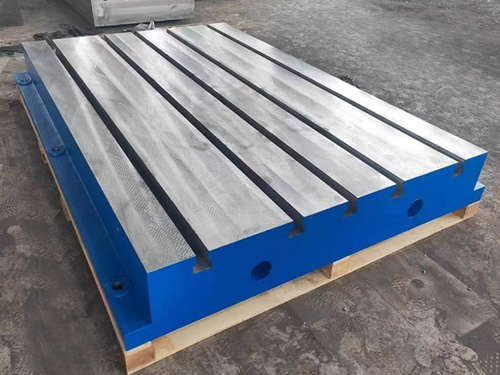

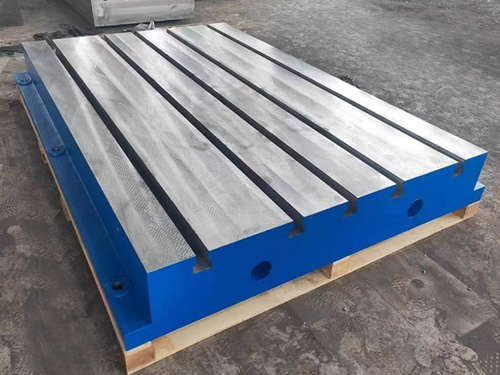

Product Details

Grey Cast Iron

Grey cast iron, also known as gray iron, is one of the most common types of cast iron. Here is a detailed introduction:

Composition and Microstructure

Composition: It mainly consists of iron, carbon, silicon, manganese, phosphorus, and sulfur. The carbon content is usually between 2.5% and 4.0%, and the silicon content is around 1.0% to 3.0%. These elements have a significant influence on the properties of grey cast iron.

Microstructure: It is characterized by a matrix of ferrite or pearlite, in which flake - like graphite is distributed. The graphite flakes are similar to "internal defects" in the metal matrix, which have a weakening effect on the matrix. However, they also endow grey cast iron with some unique properties.

Properties

Good Castability: Grey cast iron has low melting point and good fluidity, which enables it to easily fill the mold cavity during the casting process, suitable for producing complex - shaped parts.

Excellent Machinability: Due to the presence of graphite flakes, the cutting force during machining is small, and the tool wear is relatively low. It is easy to obtain a smooth surface finish, which is beneficial to reducing the processing cost and improving the processing efficiency.

Good Damping Capacity: The graphite flakes in grey cast iron can absorb and dissipate vibration energy, so it has excellent damping performance. It can effectively reduce vibration and noise in mechanical equipment, which is very important for improving the working environment and service life of equipment.

High Compressive Strength: Although its tensile strength is relatively low, grey cast iron has high compressive strength, which can withstand large compressive loads. This makes it widely used in parts that are mainly subjected to compressive stress, such as machine tool beds, engine blocks, etc.

Poor Toughness and Ductility: The flake - like graphite in grey cast iron is equivalent to micro - cracks in the matrix, which seriously weakens the continuity of the matrix. Therefore, grey cast iron has poor toughness and ductility and is prone to brittle fracture under the action of tensile stress.

Applications

Machine Tool Industry: It is widely used in the manufacture of machine tool beds, columns, worktables, etc. Due to its good damping performance and high compressive strength, it can ensure the stability and accuracy of machine tools during operation and improve the processing quality of workpieces.

Automobile Industry: It is an important material for manufacturing engine blocks, cylinder heads, gearboxes, and other parts. The good castability and machinability of grey cast iron can meet the requirements of mass production of automotive parts, and its excellent damping performance helps to reduce engine vibration and noise.

Pipe Fittings Industry: Grey cast iron is often used to make pipes and pipe fittings. Its corrosion resistance and good fluidity during casting make it suitable for producing various types of pipes with different diameters and wall thicknesses, which are widely used in water supply, drainage, and gas transmission systems.

Other Fields: It is also used in the manufacture of some general - purpose mechanical parts, such as pump bodies, valve bodies, and flywheels. In addition, grey cast iron is also commonly used in some traditional handicrafts and artistic casting fields due to its unique appearance and easy - to - shape characteristics.

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province