Product Details

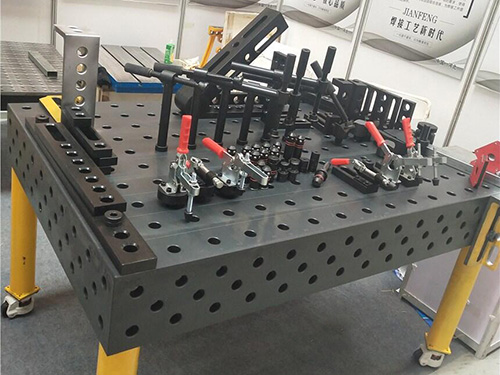

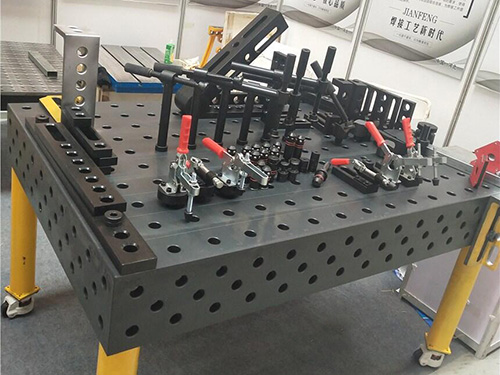

3D Welding Jig

A 3D welding jig is a specialized tool used in welding processes to hold, position, and support workpieces with high precision. It plays a crucial role in ensuring the accuracy and quality of welded components, especially in complex 3D welding applications. Here is a detailed introduction:

Structure and Components

Base Platform: Usually made of high - strength cast iron or steel, it provides a stable and flat foundation. The surface of the base platform is precisely machined and often features a grid of holes or T - slots, which are used to mount various clamping and positioning elements.

Positioning Elements: These include pins, blocks, and locators. They are designed to accurately position the workpiece in the desired 3D space. Pins are often used to define specific points or axes of the workpiece, while blocks and locators are used to constrain the movement of the workpiece in different directions.

Clamping Devices: Such as clamps, bolts, and nuts, are used to firmly hold the workpiece in place during the welding process. They ensure that the workpiece does not move or shift due to the heat and force generated during welding, thereby maintaining the accuracy of the weld joint.

Adjustable Components: Many 3D welding jigs are equipped with adjustable elements, such as screw - driven slides, pivots, and height - adjustable supports. These allow for fine - tuning of the workpiece's position and orientation to meet the specific requirements of different welding tasks.

Working Principles

Accurate Positioning: The positioning elements on the welding jig are designed according to the specific geometry and dimensions of the workpiece. By precisely aligning the workpiece with these elements, it is ensured that the weld joints are in the correct position. This is especially important for complex 3D - shaped workpieces, where even a small deviation in the position of the weld joint can affect the final quality and functionality of the component.

Stable Fixing: The clamping devices on the jig apply sufficient force to hold the workpiece firmly in place. This prevents any movement or vibration of the workpiece during welding, which could lead to inaccurate welds or defects. The clamping force needs to be adjusted according to the material and size of the workpiece to ensure both secure fixation and avoid damage to the workpiece.

Flexible Adjustment: The adjustable components of the 3D welding jig enable operators to make fine adjustments to the position and orientation of the workpiece. This is useful when dealing with different batches of workpieces that may have slight variations in dimensions or when performing different welding operations on the same jig.

Applications

Automotive Industry: In the production of car bodies, 3D welding jigs are used to assemble various sheet metal components with high precision. They ensure that the body structure is accurate and stable, meeting the strict quality standards for vehicle safety and appearance.

Aerospace Industry: For manufacturing aircraft components, such as wing structures and fuselage sections, 3D welding jigs are essential to achieve the required high precision and quality. The aerospace industry has extremely strict requirements for the dimensional accuracy and mechanical properties of welded components, and welding jigs play a crucial role in meeting these requirements.

Shipbuilding Industry: In shipbuilding, 3D welding jigs are used for welding large - scale steel structures. They help to ensure the accuracy of the ship's hull structure and the quality of the welds, which is important for the safety and stability of the ship.

General Mechanical Manufacturing: In the production of various mechanical equipment and components, 3D welding jigs are widely used to improve the efficiency and quality of welding. Whether it is the welding of complex machine tool structures or the assembly of industrial robots, welding jigs help to ensure the accuracy and reliability of the welded joints.

Advantages

Improved Welding Quality: By accurately positioning and fixing the workpiece, 3D welding jigs can significantly reduce welding errors and defects, such as misalignment, distortion, and porosity. This results in higher - quality welds with better mechanical properties and appearance.

Increased Production Efficiency: The use of welding jigs simplifies the welding process and reduces the time required for workpiece positioning and clamping. This allows for faster welding speeds and higher production volumes, improving overall production efficiency.

Enhanced Workpiece Consistency: Since the jigs ensure that each workpiece is positioned and welded in the same way, the consistency of the welded components is improved. This is beneficial for mass production, as it helps to ensure that all products meet the same quality standards.

Reduced Labor Costs: With the help of 3D welding jigs, the skill level required for welding operators is relatively reduced. The jigs guide the welding process, making it easier for operators to perform high - quality welds. This can lead to a reduction in labor costs, as less - experienced operators can also achieve good welding results.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province