Product Details

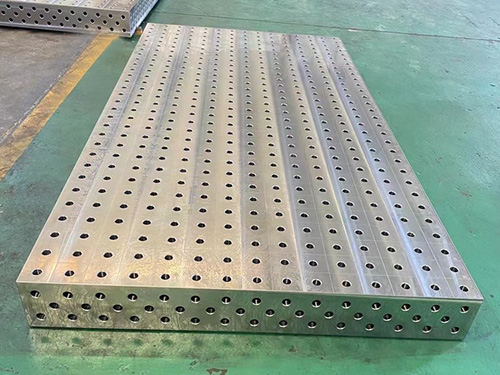

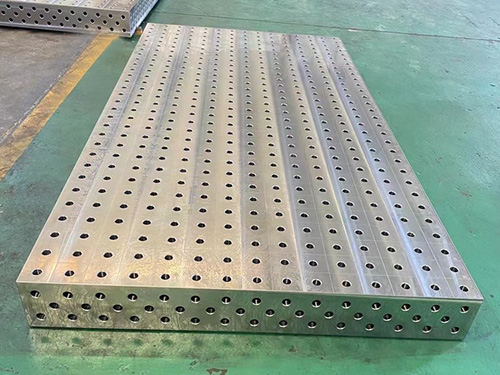

3D Welding Table

A 3D welding table is an essential piece of equipment in modern welding workshops, especially when dealing with complex three - dimensional welding tasks. It provides a stable and precise platform for welding operations, helping to improve the quality and efficiency of welding. Here is a detailed introduction:

Structure and Design

Tabletop: The tabletop of a 3D welding table is usually made of high - quality steel or cast iron. It is precisely machined to ensure a flat and smooth surface, which is crucial for accurate workpiece positioning. The tabletop is often divided into a grid - like pattern of holes or T - slots. The holes are typically of a standard size, such as 28mm or 16mm in diameter, and are evenly spaced at intervals of 100mm or 50mm. The T - slots are used to install various clamping and positioning devices.

Support Structure: The tabletop is supported by a rigid frame structure. This structure is designed to withstand the weight of the workpieces and the forces generated during the welding process without significant deformation. The legs of the support structure are usually adjustable in height to ensure the leveling of the tabletop on different floor surfaces. Some advanced 3D welding tables may also be equipped with shock - absorbing devices to reduce the impact of vibrations on the welding process.

Adjustable Elements: Many 3D welding tables are equipped with adjustable features. For example, some tables have movable magnetic clamping blocks that can be easily adjusted to different positions on the tabletop to hold workpieces of various shapes and sizes. There may also be adjustable angle - setting devices, allowing the tabletop or specific workpiece - holding fixtures to be tilted at different angles to meet the requirements of different welding positions.

Working Principles

Positioning Workpieces: The grid - like holes and T - slots on the tabletop serve as the basis for positioning workpieces. Special positioning pins or fixtures can be inserted into the holes or T - slots to accurately locate the workpieces in the X, Y, and Z axes. This ensures that the workpieces are in the correct position relative to each other before welding, reducing errors and ensuring the accuracy of the weld joints.

Clamping Workpieces: Various clamping devices, such as clamps, bolts, and nuts, are used in combination with the holes and T - slots to firmly clamp the workpieces to the tabletop. This prevents the workpieces from moving or vibrating during the welding process due to the heat and force generated, thereby maintaining the stability of the welding position and improving the quality of the welds.

Adjusting for Different Tasks: The adjustable elements on the 3D welding table allow for flexibility in adapting to different welding tasks. Operators can adjust the position and angle of the workpieces according to the specific requirements of the welding process, such as performing welding at different angles or dealing with workpieces of different geometries.

Applications

Automotive Manufacturing: In the production of automobile bodies, 3D welding tables are widely used for assembling and welding various components, such as car frames, doors, and hoods. They ensure the accurate positioning and welding of these components, meeting the high - quality requirements of automotive manufacturing.

Aerospace Industry: For manufacturing aircraft components, 3D welding tables play a crucial role in ensuring the precision and quality of welded structures. They are used to weld complex aerospace parts with high accuracy, meeting the strict standards of the aerospace industry for dimensional accuracy and structural strength.

Metal Fabrication: In metal fabrication workshops, 3D welding tables are used for a variety of tasks, including the welding of metal frames, machinery parts, and architectural metal components. They provide a stable and precise platform for welding, helping to improve the quality and efficiency of metal fabrication.

Electronics Manufacturing: In the electronics industry, 3D welding tables are used for precision welding of small - scale components, such as printed circuit boards and electronic connectors. The high - precision positioning and clamping functions of the tables are essential for ensuring the reliability of electronic connections.

Advantages

High Precision: The precise machining of the tabletop and the use of standardized positioning and clamping elements ensure high - precision workpiece positioning, which is beneficial for achieving high - quality welds with accurate dimensions and good appearance.

Flexibility: The adjustable features of 3D welding tables make them suitable for a wide variety of welding tasks. They can adapt to different workpiece shapes, sizes, and welding positions, increasing the versatility of the welding workshop.

Improved Work Efficiency: With the help of 3D welding tables, the processes of workpiece positioning and clamping are simplified and accelerated, reducing the time required for setting up welding operations. This leads to increased work efficiency and higher productivity.

Enhanced Safety: The stable structure of the 3D welding table and the reliable clamping of workpieces reduce the risk of workpiece movement or falling during welding, improving the safety of the welding operation.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province