Product Details

Welding Table with Grid Holes

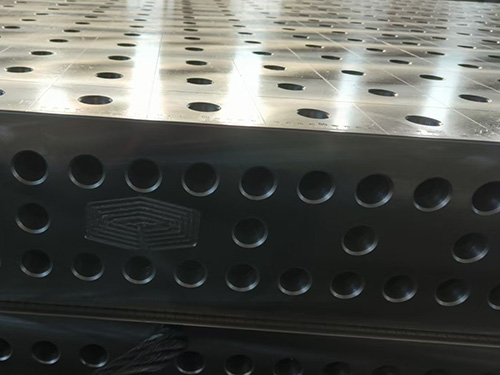

A welding table with grid holes is a specialized worktable designed to enhance the efficiency and precision of welding operations.Here's a detailed introduction:

Design and Structure

Grid Hole Pattern:The tabletop is typically made of high-quality,thick-gauge steel and is covered with a grid of evenly spaced holes.The holes are usually circular or square and are arranged in a regular matrix.The size and spacing of the holes can vary depending on the specific design of the table,but common dimensions might have holes ranging from 5 mm to 20 mm in diameter,with spacings between 25 mm and 100 mm.

Frame and Support:The tabletop is supported by a sturdy frame,usually made of steel angles or tubes.The frame is designed to provide excellent stability and load-bearing capacity,capable of supporting heavy workpieces and the forces generated during welding.Some tables may have adjustable legs to allow for height customization,ensuring ergonomic comfort for the welder.

Advantages

Versatile Fixturing:The grid holes allow for the easy installation of a variety of fixtures and clamping devices.Welders can insert bolts,pins,or specialized clamping components into the holes to secure workpieces in place.This enables precise positioning and holding of parts,which is crucial for achieving accurate welds,especially when working on complex or irregular-shaped objects.

Improved Workspace Organization:The grid pattern provides a standardized layout for organizing tools and accessories.Welders can use the holes to hang small tools,such as pliers or wire brushes,or attach magnetic holders to hold welding electrodes.This helps keep the work area clean and organized,improving workflow and reducing the time spent searching for tools.

Enhanced Heat Dissipation:The open grid design allows for better air circulation beneath the workpiece,facilitating heat dissipation.This is beneficial during welding as it helps prevent excessive heat buildup in the tabletop,which could otherwise affect the integrity of the table and potentially cause warping or damage.Additionally,improved heat dissipation can also help in cooling the workpiece more evenly,reducing the risk of thermal distortion.

Easy Cleaning and Debris Removal:The grid holes allow welding spatter,slag,and other debris to fall through the tabletop,preventing their accumulation on the work surface.This makes cleaning the table much easier,as the welder can simply sweep or vacuum the debris from beneath the table.Keeping the work area clean is not only important for maintaining a safe working environment but also helps in prolonging the life of the table.

Applications

General Welding Work:It is widely used in various welding processes,including MIG,TIG,and stick welding.Whether it's for fabricating metal structures,repairing machinery parts,or creating custom-made metal products,the welding table with grid holes provides a reliable and convenient work platform.

Prototyping and Small-Batch Production:In prototyping and small-batch production environments,where there is a need for flexibility and quick setup changes,the grid-hole table is ideal.It allows for the easy adaptation of fixtures to different workpiece designs,enabling efficient production with minimal setup time.

Educational Institutions and Training Centers:Welding schools and training centers often use tables with grid holes to teach students proper welding techniques.The grid holes help students learn how to set up and secure workpieces correctly,promoting good welding practices and ensuring safety.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province