Product Details

Welding Tables and Components

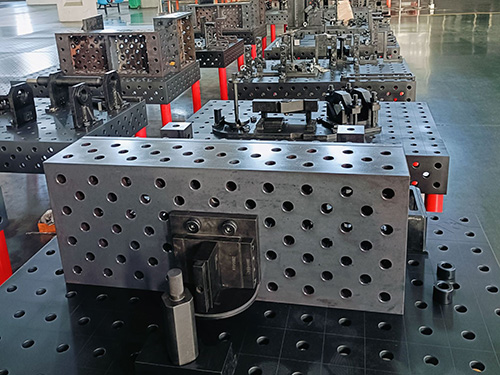

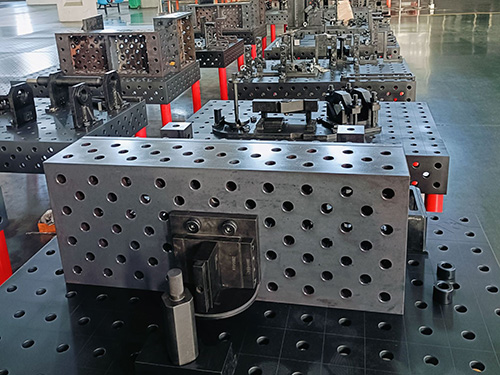

Introduction to Welding Tables and Components:

Welding Tables

Function: The welding Table is an important equipment in welding operations, mainly used to support and fix welded parts, providing a stable working platform for welding operations to ensure welding quality and improve work efficiency.

Type: As mentioned earlier, according to mobility, it can be divided into fixed and mobile types; There are regular, multifunctional, and specialized types according to their functions; There are various types of structures, such as integral and modular. Different types of welding workbenches are suitable for different welding scenarios and process requirements.

Components

Table Tops: The main working surface of a welding workbench, usually made of high-strength steel or cast iron, with good wear resistance, corrosion resistance, and high temperature resistance. The surface of the countertop has been precision machined to have high flatness and smoothness, and may be designed with T-shaped grooves, circular holes, square holes, etc. for installing fixtures and positioning devices, making it convenient to fix welding parts.

Supports: used to support countertops, generally welded from steel sections, requiring sufficient strength and stability to withstand the weight of the welded components and various forces generated during the welding process. The height and structural form of the bracket will be designed according to actual needs to meet the working height requirements of different welding processes and operators.

Fixtures: are devices used to fix welded parts, commonly including mechanical fixtures, hydraulic fixtures, magnetic fixtures, etc. Fixtures can quickly and accurately position the welded parts on the workbench, preventing them from moving or deforming during the welding process, thereby ensuring welding accuracy.

Positioning Devices: Help determine the accurate position of the weldment on the workbench, work in conjunction with fixtures, and improve the positioning accuracy of the weldment. For example, components such as locating pins and locating blocks can restrict the movement of the welded joint in a certain direction, ensuring the accurate position of the welded joint.

Other Accessories: may also include safety protection devices such as guardrails and screens, used to protect operators from welding spatter, arc light, and other injuries; And some auxiliary tools, such as lighting equipment, welding rod placement racks, etc., facilitate the welding operation.

The quality and performance of welding workbenches and their components directly affect the quality and efficiency of welding work. When selecting and using them, it is necessary to configure and maintain them reasonably according to specific welding processes and work requirements.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province