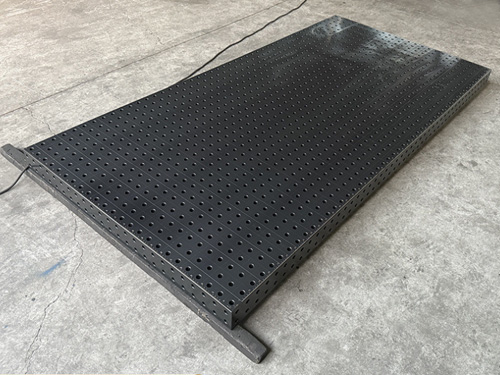

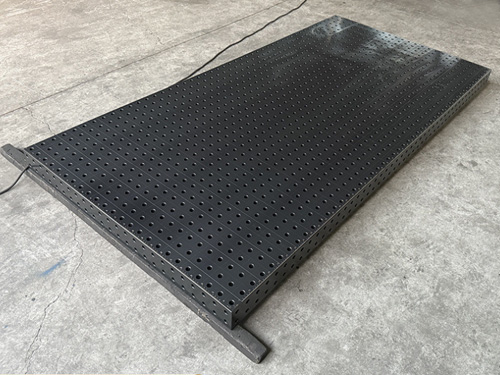

Product Details

Workbench

A 3D workbench is a specialized work platform designed for various three - dimensional work tasks, such as 3D modeling, printing, machining, and welding. Here is a detailed introduction:

Structure and Features

Tabletop: Usually made of high - strength and wear - resistant materials like steel or aluminum alloy. It has a large and flat surface area to provide a stable foundation for 3D - related equipment and workpieces. Some tabletops may be equipped with T - slots or threaded holes to facilitate the installation and fixation of fixtures and tools.

Frame: The frame is typically constructed from sturdy metal profiles, such as square steel tubes, which offer excellent stability and load - bearing capacity. It can support the weight of heavy 3D printers, milling machines, and other equipment placed on the workbench. The frame design often includes reinforced corners and cross - braces to enhance its rigidity.

Adjustable Feet: Many 3D workbenches are equipped with adjustable feet or leveling mechanisms. This allows for easy leveling of the workbench on uneven floors, ensuring that the tabletop is perfectly horizontal. Leveling is crucial for the accurate operation of 3D equipment, as any tilt or unevenness can affect the quality of 3D prints, models, or machined parts.

Storage and Cable Management: To keep the workspace organized, 3D workbenches often come with built - in storage options. This can include drawers for storing small tools, parts, and filaments used in 3D printing, as well as cabinets for larger items. Additionally, there are usually provisions for cable management, such as cable channels or clips, to keep the power and data cables of 3D equipment neatly arranged and prevent tangling.

Types

3D Printing Workbench: Specifically designed for 3D printing operations. It may have a heat - resistant surface to protect against the heat generated by the 3D printer's build platform. Some 3D printing workbenches also come with enclosures or partitions to create a more controlled environment for printing, reducing the impact of drafts and temperature variations on the print quality.

3D Modeling and Design Workbench: Focused on providing a comfortable and efficient workspace for 3D modeling and design tasks. It usually features a large, high - resolution monitor or multiple monitors for detailed viewing of 3D models. The workbench may also have a dedicated area for a computer tower, keyboard, and mouse, with ergonomic considerations to reduce operator fatigue during long - hours of work.

3D Machining Workbench: Intended for use with 3D machining tools such as CNC milling machines and routers. It needs to be extremely stable and rigid to withstand the vibrations and forces generated during the machining process. The tabletop may have a special coating or surface treatment to resist scratches and wear from the cutting tools, and there are often coolant - collection systems and chip - removal mechanisms integrated into the design.

3D Welding Workbench: As mentioned earlier, this type of workbench is used for 3D welding applications, especially in the context of fabricating complex metal structures. It typically has a flat and fire - resistant tabletop, with fixtures and clamps to hold the workpiece in place during welding. Some 3D welding workbenches may also have adjustable angles or rotating features to allow for better access to different parts of the workpiece.

Functions and Advantages

Accuracy and Stability: The 3D workbench's robust construction and stable surface ensure that 3D equipment operates with high accuracy. This is crucial for producing high - quality 3D prints, precise 3D - machined parts, and accurate 3D models. The stability of the workbench helps to minimize errors and ensures consistent results.

Enhanced Workspace Organization: With dedicated storage and cable management systems, a 3D workbench keeps the workspace clean and organized. This allows for easy access to tools, materials, and equipment, reducing the time wasted on searching for items and improving overall work efficiency.

Versatility: Many 3D workbenches are designed to be versatile, accommodating different types of 3D - related equipment and tasks. For example, a single workbench can be used for both 3D printing and 3D modeling by simply rearranging the equipment and tools. This versatility makes the workbench a cost - effective investment for users who engage in multiple 3D - related activities.

Ergonomics: Some 3D workbenches are designed with ergonomics in mind, taking into account the height and posture of the operator. Adjustable height features and comfortable seating positions help to reduce physical strain and fatigue, allowing for longer and more productive work sessions.

Applications

3D workbenches are widely used in various fields, including manufacturing, engineering, design, education, and research. In manufacturing, they are used for prototyping, product development, and small - batch production of 3D - printed or machined parts. In the design industry, 3D workbenches are essential for creating detailed 3D models and visualizations. In educational institutions, they are used to teach students about 3D technology, including 3D printing, modeling, and machining. In research laboratories, 3D workbenches provide a platform for conducting experiments and developing new 3D - related technologies and materials.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province