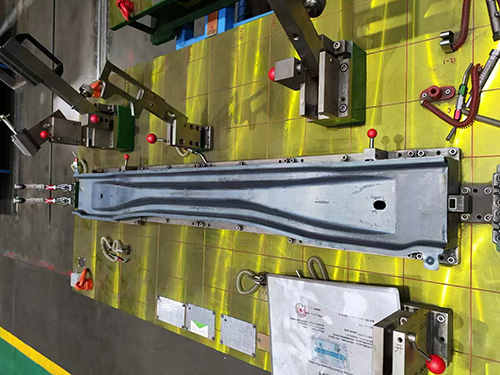

Product Details

3D 5-Axis Laser Cutting Processing

3D 5-Axis Laser Cutting Processing uses the high energy density of laser beams to heat materials locally to melting or vaporization temperatures in a non-contact manner.Through a five-axis linkage system,it precisely controls the laser beam to move freely along three coordinate axes and adjusts the rotation and swing of the laser head,enabling cutting,drilling,marking,and other processes on materials with complex 3D shapes.

Equipment Composition

Laser Generation System:Produces high-energy-density laser beams,such as fiber lasers and CO₂lasers.Different types of lasers are suitable for various materials and processing requirements.

Five-Axis Linkage System:Consists of three linear motion axes(X,Y,Z axes)and two rotation axes(usually A and C axes).It allows the laser head to adjust at any angle and position in 3D space,ensuring the laser beam accurately irradiates the workpiece’s target area.

Control System:Coordinates the operation of the laser generation system and five-axis linkage system.Based on input CAD/CAM model data or preset processing instructions,it precisely controls the laser beam’s trajectory,energy output,and processing parameters(e.g.,cutting speed,frequency,power).

Worktable and Fixtures:Fix the workpiece to ensure stability and accuracy during processing.Advanced worktables may feature automatic loading/unloading functions to improve efficiency.

Auxiliary Systems:Include cooling systems and gas-blowing systems.The cooling system reduces the equipment’s temperature during operation to ensure normal functioning;the gas-blowing system injects auxiliary gases(e.g.,oxygen,nitrogen)into the cutting area to remove slag,enhance cutting quality,and increase speed.

Advantages

High Precision:Five-axis linkage enables multi-dimensional precise control of the workpiece,ensuring positioning and motion accuracy of the laser beam during processing,reaching micron-level precision.It meets the high-precision requirements of industries like automotive and aerospace for components.

High Flexibility:No molds are needed;cutting is directly performed based on CAD drawings.It quickly adapts to design changes,offering significant advantages for small-batch,multi-variety processing of complex-shaped workpieces,easily handling 3D curved surfaces and irregular structures.

High Efficiency:3D cutting speeds can reach 20m/min,approximately 3 times faster than traditional processing.Intelligent nesting systems improve material utilization,and technologies like flying cutting enable continuous,uninterrupted processing,greatly reducing production time.

Excellent Cut Quality:Laser energy is precisely focused,resulting in smooth,deformation-free cuts with burr heights<0.1mm,minimal heat-affected zones,and good cut perpendicularity.Narrow kerf widths reduce material waste,and the high-quality cut surface typically requires no secondary grinding,minimizing post-processing.

Non-Contact Processing:Laser cutting is non-contact,avoiding mechanical stress or deformation on the workpiece—ideal for thin-walled parts,fragile materials,and surface-sensitive workpieces.It also eliminates tool wear,reducing processing costs.

Application Fields

Automotive Manufacturing:Precisely processes automotive metal components such as bumpers,door panels,and new energy vehicle battery trays,enabling cutting,hole drilling,and trimming of complex curved surfaces to improve precision,efficiency,and reduce costs.

Aerospace:Suitable for aircraft engine blades,wing structures,and aerospace components,meeting the high precision,quality,and complex shape requirements of the aerospace industry.

Mold Processing:Accurately cuts complex mold cavities and cores,improving manufacturing precision,efficiency,and shortening mold production cycles.

Home Appliance Industry:Processes complex-shaped parts in home appliances,such as air conditioner outer casings and washing machine inner drums,enhancing product appearance and performance.

3C Electronics:Cuts housings,internal structures,and electronic accessories for smartphones,tablets,etc.,meeting the high precision,miniaturization,and customization needs of 3C products.

Medical Devices:Manufactures complex medical components like orthopedic implants and dental instruments,ensuring precision and quality to meet strict medical industry standards.

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province