Product Details

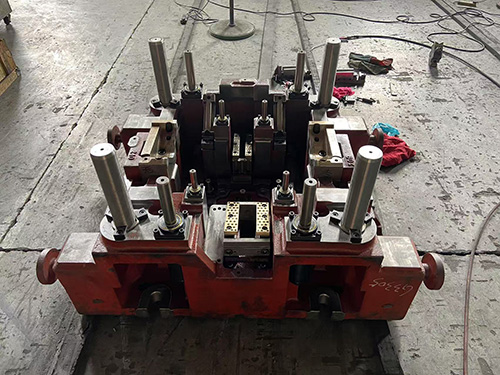

Automobile mold

Automobile molds refer to molds used in the automotive field and are known as the"mother of the automobile industry".Here is a detailed introduction to automobile molds:

Classification

Classified by process nature

Blanking dies:Molds that separate materials along closed or open contour lines,such as blanking dies,punching dies,cutting dies,etc.

Bending dies:Molds that bend sheet blanks or other blanks along a straight line to obtain workpieces with a certain angle and shape.

Drawing dies:Molds that make sheet blanks into open hollow parts or further change the shape and size of hollow parts.

Forming dies:Molds that directly copy and form blanks or semi-finished workpieces according to the shape of the convex and concave dies in the drawing,with only local plastic deformation of the material itself,such as bulging dies,necking dies,etc.

Classified by the degree of process combination

Single-process dies:Molds that complete only one stamping process in one stroke of the press.

Compound dies:Molds with only one station that complete two or more stamping processes simultaneously at the same station in one stroke of the press.

Progressive dies:Molds with two or more stations in the feeding direction of the blank,which sequentially complete two or more stamping processes at different stations in one stroke of the press.

Classified by product processing method

Blanking and shearing dies:Dies that complete work through shearing action,common forms include cutting dies,blanking dies,punching dies,etc.

Bending dies:Dies that bend flat blanks into an angled shape,such as ordinary bending dies,cam bending dies,etc.

Drawing dies:Dies that make flat blanks into bottomed and seamless containers.

Forming dies:Dies that change the shape of blanks by various local deformation methods,including convex forming dies,curling forming dies,etc.

Compression dies:Dies that use strong pressure to make metal blanks flow and deform into the required shape,including extrusion dies,embossing dies,etc.

Characteristics

Complex mold structure:Automobile molds need to accurately shape the complex shapes of auto parts,so their structures are usually relatively complex,involving the cooperation and movement of multiple components.

Dense process arrangement:To ensure the precision and quality of auto parts,the processing procedures of automobile molds are usually dense,requiring multiple processes of processing and treatment.

High precision requirements:Auto parts have high precision requirements,so automobile molds also need to have high precision to ensure that the produced parts meet the design requirements.

High surface quality requirements:The surf

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province