Product Details

Welding Table Accessories Kit

Our Welding Table Accessories Kit is a "versatile tool kit" tailored to enhance the flexibility and professionalism of welding operations. Whether optimizing existing welding table functions or handling complex welding tasks, a set of accessories can meet diverse needs, helping you easily achieve a leap from basic operations to high-end processes!

1、 Full scene adaptation to meet diverse needs

Precise positioning combination: high-precision positioning pins, magnetic positioning blocks, and three-dimensional adjustable support seats can quickly lock the position of the workpiece, with an error controlled within ± 0.05mm, suitable for high demand welding scenarios such as aerospace precision components and automotive molds.

Strong clamping system: fast clamps, T-shaped groove pressure plates, and universal fixtures provide a stable clamping force of up to 500kg, easily handling heavy workpieces and preventing displacement or shaking during welding.

Auxiliary efficiency enhancing tools: anti splash baffle, welding slag collection tray, and cable storage rack, not only protect the surface of the welding table, but also optimize the working environment, improve safety and cleanliness.

2、 Modular design, optional combination and upgrade

All accessories adopt standardized interfaces and are perfectly compatible with the T-shaped slots and positioning holes of mainstream welding stations. You can freely match according to task requirements, such as installing flexible magnetic suction cups for thin plate welding or adding heavy-duty support legs for thick plate operations. No need for professional tools, parts replacement can be completed within 10 minutes, making the welding station a customized workstation in seconds!

3、 High quality material selection, durable and reliable

The main body of the accessory is made of high-strength alloy steel, aviation grade aluminum alloy and other materials. The surface is treated with wear-resistant coating and anti-corrosion technology, which can withstand high temperature, strong impact and frequent disassembly and assembly. The quick clamp spring has undergone 100000 fatigue tests, and the hardness of the positioning pin has reached HRC55, ensuring long-term performance without degradation and reducing maintenance costs.

4、 Widely used, covering multiple industries

From assembly line welding in automobile manufacturing to creative processing in metal art studios; Our accessory kits are compatible with everything from the assembly of large structural components in shipbuilding heavy industry to precision welding in electronic workshops. We have helped over 2000 companies worldwide improve their production efficiency by more than 30%, becoming a trusted choice for welding professionals.

Instantly equip your welding table with a welding table accessory kit, bringing new vitality to your welding table! Whether beginners or experienced craftsmen, they can unlock more possibilities and create efficient and precise welding solutions through this set of accessories!

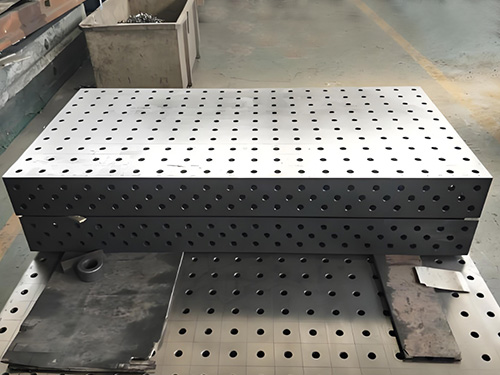

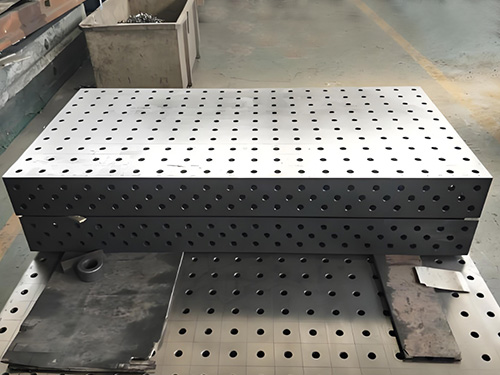

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province