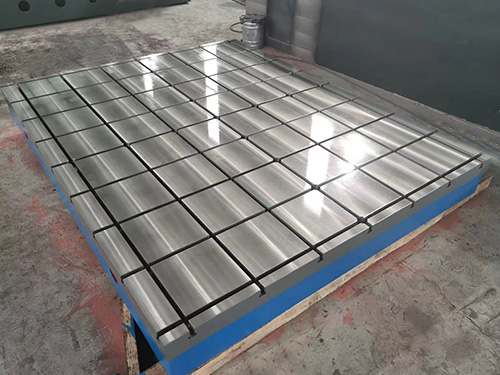

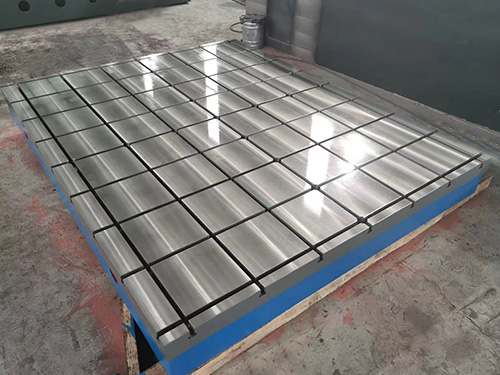

Product Details

Cast Iron Platform for Testing,Scribing and Assembly

The surface of Cast Iron Platform for Testing,Scribing and Assembly is usually treated with the following heat treatment and surface treatment processes:

Heat treatment process

Stress relief annealing

Purpose:To eliminate the internal stress generated by the cast iron platform during the casting process,prevent the platform from deforming due to the release of internal stress during use,and improve dimensional stability.

Process:Heat the cast iron platform to 550-650℃,hold it for a certain period of time(usually calculated as 1 hour per 25mm thickness of the platform),then slowly cool it to 200-300℃with the furnace,and then air cool it out of the furnace.

quenching

Purpose:To improve the hardness and wear resistance of the surface of the cast iron platform,thereby increasing its service life.

Process:Select the appropriate quenching medium(such as water,oil,etc.)based on the material of cast iron and the specific requirements of the platform.Heat the platform to 30-50℃above the critical temperature,hold for an appropriate period of time,and quickly cool it in the quenching medium.For example,for cast iron platforms made of medium carbon steel or medium carbon alloy steel,oil quenching can be used to achieve better quenching depth and surface quality.

tempering

Purpose:To eliminate internal stress after quenching,reduce material brittleness,adjust the balance between hardness and toughness,and achieve good comprehensive mechanical properties for cast iron platforms.

Process:The tempering temperature is usually between 150-650℃,and the specific tempering temperature and time should be selected according to the performance requirements of the platform.Low temperature tempering(150-250℃)is mainly used to improve the hardness and wear resistance of parts;Medium temperature tempering(350-500℃)can achieve higher elastic limit and yield strength;High temperature tempering(500-650℃)can endow parts with excellent comprehensive mechanical properties and is commonly used in important structural components.

Surface treatment process

Nitriding treatment

Purpose:To form a nitride layer with high hardness,good wear resistance,and strong corrosion resistance on the surface of a cast iron platform,in order to improve the surface's hardness,wear resistance,bite resistance,and corrosion resistance.

Process:Place the platform into a nitriding furnace,introduce gases such as ammonia,and perform nitriding treatment at a certain temperature(usually 500-600℃)and pressure.The nitriding time depends on the required thickness of the nitriding layer and is generally several tens of hours.For example,for cast iron platforms that require high wear resistance,a nitride layer with a thickness of 0.3-0.5mm can be obtained through nitriding treatment,and its surface hardness can reach HV900-1200.

Hard chrome plating treatment

Purpose:To improve the hardness,smoothness,and corrosion resistance of the surface of cast iron platforms,while reducing the surface friction coefficient,making the platform surface more wear-resistant,corrosion-resistant,and easy to clean.

Process:First,the surface of the platform is pre treated,including processes such as oil removal and rust removal,and then the platform is placed in a chrome plating tank for electroplating.Chromium plating solution usually contains components such as chromic acid and sulfuric acid.Under certain current density and temperature conditions,chromium ions are reduced and deposited on the platform surface to form a hard chromium layer.The thickness of the hard chrome plating layer is generally between 0.02-0.05mm.

Blackening treatment

Purpose:To form a black oxide film on the surface of a cast iron platform,mainly used to prevent rusting of the platform,and also has a certain decorative effect,making the platform surface have a uniform black appearance.

Process:Place the platform in a black liquor containing sodium hydroxide,sodium nitrite,and other components,and perform an oxidation reaction at a certain temperature(usually 135-145℃)to form a black film of iron oxide on the surface of the platform.The blackening treatment time is usually 10-30 minutes,depending on the material and surface requirements of the platform.

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province