Product Details

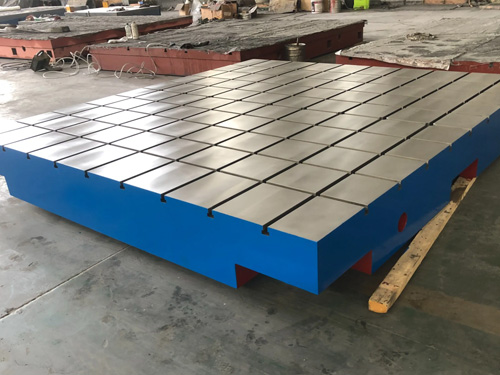

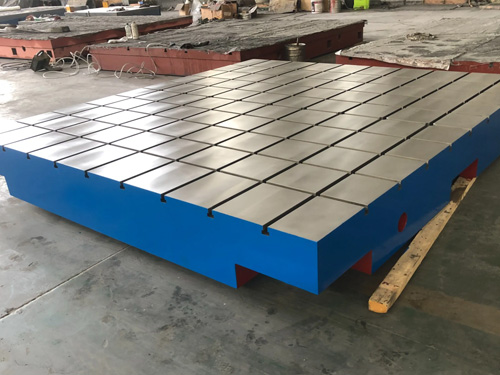

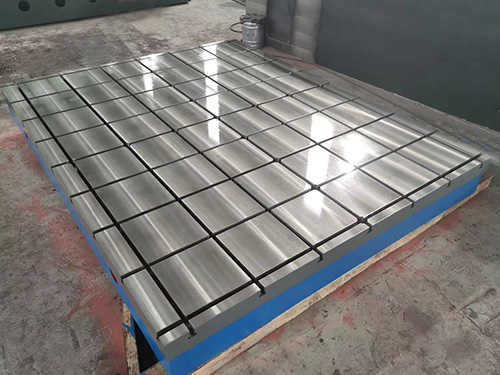

Cast iron platform-Cast iron surface plates

Cast iron platform-Cast iron surface plates is the main benchmark tool for scribing.It should be placed stably and firmly,and the top should be kept horizontal.Cast iron platform-the plane of cast iron panel shall be used uniformly to avoid local grinding and concave,and its surface shall not be collided or knocked,and shall be kept clean frequently.Cast iron platform-when cast iron panel is not used for a long time,it shall be coated with oil for rust prevention and covered with protective cover.Cast iron platform-Cast iron surface plates the definition of scribing:according to the requirements of the drawing,the operation of scribing the contour line of the part to be machined or the point and line as the reference on the blank or semi-finished workpiece with a scribing tool is called scribing

When installing the cast iron platform cast iron panel,wipe the cast iron flat face clean.If there is no problem,after finding out the situation,avoid a radical collision between the workpiece and the cast iron flat face in the process of use,and prevent damage to the cast iron platform cast iron panel face;The weight of the workpiece shall not exceed the rated load of the cast iron plate,otherwise the work quality will be reduced,the structure of the cast iron plate may be damaged,and even the cast iron plate will be deformed,so that it can not be used.

Cast iron platform-Cast iron surface plates is used for various inspection work,such as the datum plane for measurement,various machine tool testing and measurement,checking the dimensional accuracy and line position deviation of parts,and making lines.Cast iron plate is the product of 20 industries such as machine tool,machinery manufacturing and electronic manufacturing.Cast iron plate is a bench for scribing,measuring,riveting and welding,and tooling technology.Cast iron plate can also be used as a mechanical test bench,and so on.

There will be some product defects in the production process of cast iron platform cast iron panel.As long as the correct method can be used to make up,the defects of cast iron platform cast iron panel working face can not be ignored.The main defects of cast iron platform cast iron panel include:air hole,sand hole,sand inclusion,shrinkage porosity,etc.The defects of cast iron platform cast iron panel have detailed provisions for treatment in the mechanical industry standard of the people's Republic of China jb/t 7974-2000.Cast iron platform-the service life of cast iron panel is closely related to defects.Therefore,the defects of cast iron platform cast iron panel should be treated strictly according to the process requirements.Cast iron platform-Cast iron surface plates has inherent casting defects on the flat working surface with accuracy grade lower than"00",the sand with diameter less than 15mm is allowed to be blocked with the same material,and its hardness should be lower than that of the surrounding materials.There shall be no more than four blocked parts on the working face,and the distance between them shall not be less than 80mm.Cast iron platform-the working surface of cast iron panel shall be free of rust,scratch,bruise and other appearance defects affecting the use.

The flatness of the working surface of cast iron platform cast iron panel shall be within 25mm square area when inspected by spot method.For grade 0 cast iron platform cast iron panel and grade 1 cast iron platform cast iron panel,there shall be no less than 25 points,grade 2 cast iron platform cast iron panel shall be no less than 20 points,and grade 3 cast iron platform cast iron panel shall be no less than 12 points.

When grinding cast iron platform cast iron panel,any two of the three cast iron platforms cast iron panel shall have a number of spots within 25mm square area when they are mutually inspected.In this case,the cast iron platform-cast iron panel has a virtually flat surface.Note:the inspection of two scraped cast iron platforms cast iron panels behind cast iron platforms cast iron panels by spot method can only determine that the surfaces of the two cast iron platforms cast iron panels can be closely combined,but it does not indicate that the flatness of the cast iron platforms cast iron panels is qualified,because the surfaces of the two cast iron platforms cast iron panels can be scraped and grinded to form a spherical surface.Straightness deviation can also be checked by dimension and dial indicator.During the inspection,put the square above the surface of the cast iron platform cast iron panel.Then put the dial indicator and bracket equipped with tolerance reading on the working surface of the tested cast iron platform cast iron panel,and make the measuring head on the dial indicator contact with the square.When moving the bracket with a dial indicator,you can see the straightness deviation of the inspected cast iron platform cast iron panel plane.

The flatness of the plane of the grinding plate used in the measurement is checked by the light wave interferometry using the aforementioned optical plane method.

Angle cast iron platform-cast iron panel is used to check the position of mutually perpendicular planes.Angled cast iron platform-cast iron panel has two scraped cast iron platforms at vertical angles to each other-cast iron panel surface.The inspection is carried out according to the spot method.In terms of manufacturing and application methods,angle cast iron platform cast iron panel and cast iron platform cast iron panel have a lot in common,but in essence,they are angle measuring tools and angle rulers with wide surface,which only play a secondary role in flatness inspection.

Cast iron platform-Cast iron surface plates is a plane reference measuring tool for workpiece detection or marking.Cast iron platform-Cast iron surface plates is a kind of flat plate,which is adjusted to the horizontal plate after installation,and the load is evenly distributed on each fulcrum.Ambient temperature(20±5)℃.Avoid vibration during use.

Cast iron platform-Cast iron surface plates is manufactured according to t7974-1999 standard.The products are made of rib plate and box type.The working surface of cast iron platform-cast iron panel/cast iron platform-cast iron panel is rectangular,square or circular,and the material is ht200-300,QT400-600,ZG15-45。The working face of cast iron platform cast iron panel adopts the scraping process,and the working face can be processed with V-shaped,T-shaped,U-shaped grooves,dovetail grooves,round holes,long holes,etc.

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province