Product Details

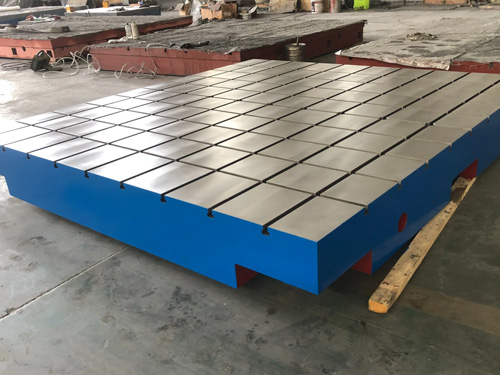

Cast Iron Platform T-slot Cast Iron Surface Bed

A T-slot cast iron platform,also known as a T-slot cast iron surface bed,is a specialized type of cast iron platform with unique features and applications.Here is a detailed introduction:

Structure and Features

T-slot design:The most prominent feature is the T-shaped groove on the platform surface.These grooves are evenly distributed and run through the platform in both the longitudinal and transverse directions.The T-slots are used to install work-holding fixtures,clamps,and other accessories.The width and depth of the T-slots are standardized according to different platform specifications,and they provide a convenient and reliable connection method for fixing workpieces and tools.

High-quality cast iron material:It is made of high-quality cast iron,usually gray cast iron or ductile cast iron.Cast iron has excellent mechanical properties,such as high rigidity,good wear resistance,and stability.It can withstand heavy loads and maintain high-precision flatness and dimensional accuracy over a long period.

Precision-machined surface:The surface of the T-slot cast iron platform undergoes precision machining,including milling,grinding,and lapping processes.This ensures that the platform has a high-level flatness and a low-roughness surface,providing an accurate reference plane for various manufacturing and inspection operations.The flatness error of the platform surface can reach very low values,typically within the range of a few micrometers to tens of micrometers,depending on the accuracy level of the platform.

Applications

Fixture installation and workpiece clamping:In mechanical processing and manufacturing,the T-slots are mainly used to install various fixtures and clamps.Workpieces can be quickly and accurately fixed on the platform through the T-slots,ensuring the stability and accuracy of the workpiece during processing.This is particularly important for complex-shaped workpieces and those requiring high-precision processing,as it helps to improve processing efficiency and quality.

Machine tool workbench:T-slot cast iron platforms are often used as workbenches for machine tools such as milling machines,planers,and grinders.The T-slots allow for easy installation of tooling and workpieces,enabling precise positioning and movement during machining operations.They provide a stable and reliable working surface,which is conducive to improving the machining accuracy and surface quality of workpieces.

Inspection and measurement:In the inspection and measurement process,the T-slot cast iron platform serves as a reference surface.Measuring instruments such as coordinate measuring machines,dial indicators,and calipers can be used in combination with the platform to measure the size,shape,and position accuracy of workpieces.The T-slots can also be used to install measurement fixtures,facilitating the accurate measurement of workpieces.

Assembly and debugging:During the assembly and debugging of mechanical equipment,the T-slot cast iron platform provides a convenient working surface.Components can be placed and assembled on the platform,and the T-slots can be used to install positioning and clamping devices to ensure the accurate installation and connection of each component.This helps to improve the assembly efficiency and quality of mechanical equipment.

Maintenance and Use Precautions

Regular cleaning:After each use,the platform should be cleaned in a timely manner to remove dust,chips,oil stains,and other impurities on the surface and in the T-slots.A clean,soft-bristled brush and a mild detergent can be used for cleaning.After cleaning,the platform should be dried to prevent rust.

Rust prevention:Cast iron is prone to rust,so rust-prevention measures should be taken.Apply an appropriate amount of anti-rust oil on the surface of the platform and in the T-slots to prevent contact between the cast iron and air and moisture.In a humid environment,the frequency of applying anti-rust oil should be increased.When the platform is not in use for a long time,it should be covered with a plastic film or other protective materials.

Avoid overloading:Although the T-slot cast iron platform has high load-bearing capacity,it should not be overloaded.Excessive load may cause deformation of the platform,affecting its flatness and accuracy.When using,it is necessary to ensure that the load of the workpiece and fixture does not exceed the rated load of the platform.

Regular inspection and calibration:The platform should be inspected and calibrated regularly to ensure its accuracy and performance.The calibration cycle is generally determined according to the frequency of use and accuracy requirements,usually once a year or half a year.Professional calibration institutions can be commissioned to check the flatness of the platform surface,the accuracy of the T-slots,and other parameters.If any problems are found,they should be repaired or adjusted in a timely manner.

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province