Product Details

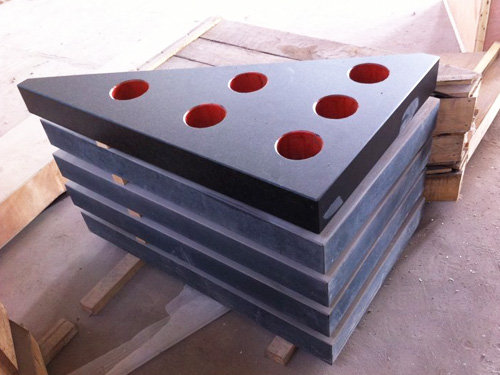

Black granite ruler

Choosing the appropriate precision grade for your black granite ruler requires comprehensive consideration of multiple factors.Here are some reference points:

Accuracy requirements for measurement tasks

High precision measurement:If used in precision machining,optical instrument manufacturing,aerospace and other fields,the accuracy requirements for part dimensions and positional tolerances are extremely high,usually requiring the selection of black granite rulers with Class 00 or Class 0 accuracy.For example,when manufacturing high-precision optical lens molds,it is necessary to accurately control the flatness and straightness of the mold to ensure the optical performance of the lens.At this time,a ruler with a precision of 00 level can meet the measurement accuracy requirements of sub micron level.

General precision measurement:For general measurements in ordinary mechanical processing and electronic product manufacturing,such as measuring the basic dimensions of parts and checking the levelness of equipment installation,a level 1 precision ruler is often sufficient to meet the requirements.Its measurement error is within the allowable range,which ensures product quality and has a high cost-effectiveness.

Stability of the usage environment

Stable environment:In laboratories or high-precision processing workshops with relatively stable environmental conditions such as temperature and humidity,it is advisable to choose rulers with higher precision levels,as a stable environment is conducive to leveraging their high-precision advantages and ensuring the accuracy and repeatability of measurement results.

Changing environment:If the temperature and humidity of the usage environment change significantly,or there are interference factors such as vibration,then a ruler with a high precision level may not be able to fully utilize its accuracy advantages.In this case,it is more appropriate to choose a ruler with a lower precision level but strong resistance to environmental interference.For example,in outdoor construction sites,the environmental conditions are complex and varied,and a level 1 precision ruler is more suitable for this environment.Although the accuracy is slightly lower,it can meet the general requirements for dimensional measurement in construction.

Cost factors

High cost and high precision:The higher the precision level of the black granite ruler,the more complex the manufacturing process and the higher the cost.Class 00 and Class 0 rulers are usually expensive and require significant procurement and maintenance costs,including regular calibration fees.

Cost benefit balance:For some application scenarios where measurement accuracy requirements are not extremely strict,choosing a lower precision level ruler can effectively reduce costs while meeting measurement needs.For example,in the general furniture manufacturing industry,using a level 1 precision ruler can meet the requirements for board size and component installation accuracy,without the need to spend high costs to purchase high-precision level rulers.

The skill level of the operators

Professional operator:If the operator has received professional training,has rich measurement experience and high operational skills,is proficient in using high-precision measurement tools,and can correctly handle measurement data and errors,then a higher precision level ruler can be selected to fully utilize its performance and obtain more accurate measurement results.

Ordinary operators:For operators with relatively low operational skills or low requirements for measurement accuracy,it is more appropriate to choose a ruler with moderate accuracy level.Due to the high requirements for operation methods and skills for high-precision rulers,if the operator is not proficient,they may not be able to fully utilize their accuracy advantages and may instead increase measurement errors.

When choosing the accuracy level of black granite ruler,it is necessary to comprehensively consider the accuracy requirements of the measurement task,the usage environment,the cost,and the skills of the operators,weigh the pros and cons of all aspects,and choose the product that best suits one's needs.

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province