Product Details

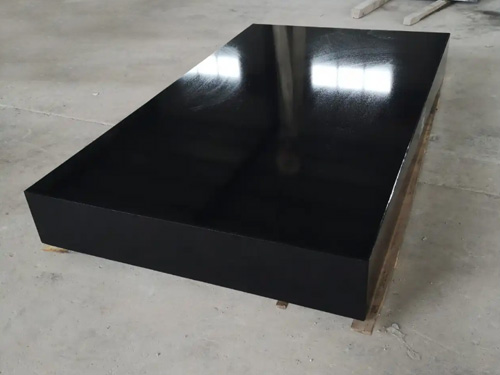

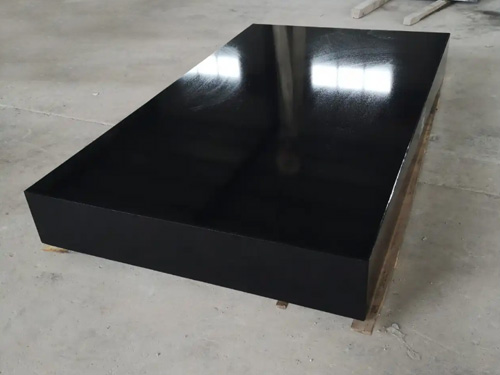

Black Grade 00 Precision Granite Surface Plate for Lab Inspection Room

Black Grade 00 Precision Granite Surface Plate for Lab Inspection Room characteristic

High precision:Granite slabs with 00 level precision have extremely high flatness,and according to relevant standards,their flatness tolerance is usually very small.For example,for a grade 00 granite slab with dimensions of 300mm×300mm,the flatness tolerance can be controlled within a few micrometers,providing a precise reference plane for laboratory precision measurement and inspection.

Material stability:Made from high-quality underground rock layers,after billions of years of natural aging,the internal stress is completely eliminated,the organizational structure is uniform,the coefficient of linear expansion is extremely small,and it will hardly deform under conventional temperature changes,ensuring long-term accuracy and stability.

Good wear resistance:The main mineral components are pyroxene,plagioclase,etc.,with a hardness of 6-7 on the Mohs scale.The texture is hard and extremely resistant to wear.Even under frequent use and heavy load conditions,it can maintain the flatness and accuracy of the working surface,and has a long service life.

Corrosion resistance:It has good resistance to acid and alkali corrosion,does not rust,does not need to be coated with oil,is not easy to stick to dust,can maintain stable performance in various corrosive environments,and is easy to maintain.It is suitable for laboratories in different chemical environments.

Non magnetic and insulating properties:As a non-metallic material,it has no magnetic reaction and good insulation performance,which will not interfere with electronic instruments,magnetic materials,etc.in the laboratory,ensuring the accuracy of measurement results and the normal operation of instrument equipment.

application

Dimensional accuracy testing of parts:can be used to measure geometric accuracy such as flatness,straightness,parallelism,perpendicularity,etc.of parts.For example,in the field of mechanical processing,placing the processed parts on a 00 grade granite flat plate and using measuring tools such as micrometers and height gauges can accurately measure the surface deviation of the parts and determine whether they meet the design requirements.

Instrument calibration:Many laboratory instruments such as electronic scales,microscopes,coordinate measuring instruments,etc.need to be calibrated before use.The 00 grade granite plate can provide accurate calibration benchmarks for these instruments,ensuring their measurement accuracy and reliability.

Optical experiment:In optical experiments,it is used to build an optical platform,providing a stable and flat foundation for the installation and debugging of optical components,ensuring the optical path accuracy of the optical system,and reducing optical errors caused by uneven platforms.

Electronic component testing:In the electronics industry,it can be used to test the flatness,coplanarity,etc.of electronic components.For example,in the process of integrated circuit packaging,granite plates are used to test the flatness of chip packaging to ensure packaging quality.

maintenance

Cleaning:Regularly wipe the surface of the tablet with a clean,soft cloth to remove dust,oil stains,and other impurities.Avoid using rough or corrosive cleaning agents to avoid scratching or corroding the surface of the flat plate.

Avoid collision:During transportation and use,be careful and avoid collisions with other hard objects to prevent scratches,dents,or damages on the surface of the flat plate,which may affect accuracy.

Storage environment:The tablet should be stored in a dry,constant temperature,and humidity environment,avoiding direct sunlight and drastic changes in temperature and humidity.It is best to place the tablet on a dedicated bracket to prevent deformation due to long-term placement on uneven ground.

Regular calibration:To ensure the accuracy of the tablet,it is necessary to regularly send it to a professional metrology institution for calibration.The calibration cycle is generally determined based on the frequency of use and actual needs,usually one or six months.

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province