Product Details

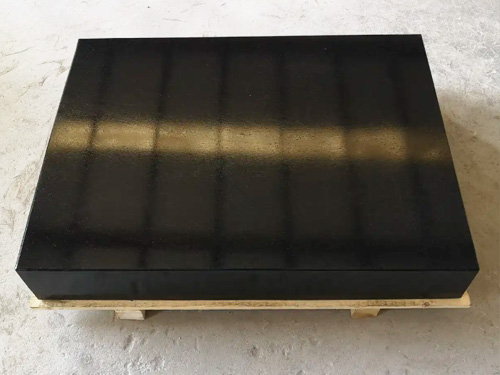

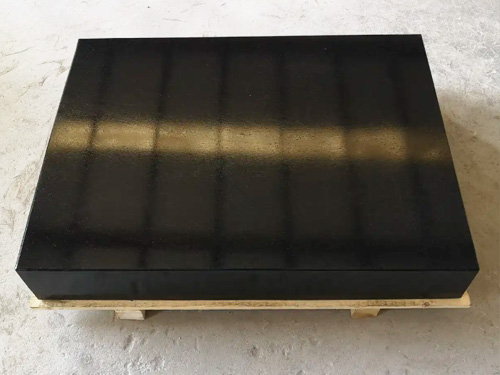

Granite surface plate

A granite surface plate is a precision measuring tool widely used in various industries.Here is a detailed introduction:

Characteristics

High Flatness:It has an extremely flat surface.The flatness error of high-grade granite surface plates can be within a few micrometers.For example,a 0-grade 500mm×800mm granite surface plate may have a flatness tolerance of around 5μm,providing an accurate reference plane for measurement and inspection.

Good Stability:Granite is a natural stone that has undergone long-term geological changes.It has low thermal expansion coefficient and is not easily affected by temperature changes.It also has high hardness and wear-resistance,with low internal stress,which ensures that the plate maintains stable geometric accuracy during long-term use.

Excellent Corrosion Resistance:It has good resistance to acids,alkalis,and other chemical substances,which can avoid surface corrosion and damage caused by chemical reactions,thereby maintaining the accuracy and service life of the surface plate.

Applications

Precision Machining Inspection:In the field of mechanical manufacturing,it is used to check the flatness,straightness,and parallelism of machined parts.Workers can place the parts on the granite surface plate and use measuring tools such as dial indicators to measure the deviation of the part surface from the reference plane to ensure that the parts meet the required accuracy standards.

Metrology and Calibration:It serves as a calibration benchmark in metrology laboratories.Other measuring instruments and fixtures,such as height gauges and square rulers,can be calibrated by comparing with the granite surface plate to ensure the accuracy and traceability of the measurement system.

Assembly and Alignment:In the assembly process of precision equipment,such as the assembly of optical instruments and electronic devices,the granite surface plate provides a flat and stable platform.It is used to ensure the correct installation and alignment of components to ensure the overall performance and quality of the equipment.

Maintenance and Care

Regular Cleaning:Use a clean,soft-cloth to wipe the surface of the granite surface plate regularly to remove dust,oil,and other contaminants.Avoid using hard or abrasive cleaning tools to prevent scratching the surface.

Proper Storage:Store the surface plate in a dry,clean,and temperature-controlled environment.Avoid placing it in an environment with large temperature and humidity changes to prevent deformation.It is best to place it on a special support frame to avoid direct contact with the ground.

Handle with Care:During use and transportation,handle the granite surface plate with care to avoid collisions,drops,and strong vibrations.Any damage to the surface or edges of the plate can affect its measurement accuracy.

Periodic Calibration:To ensure its accuracy,the granite surface plate should be sent to a professional metrology institution for periodic calibration.The calibration cycle is usually determined according to the frequency of use and the required accuracy,generally once a year or as needed.

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province