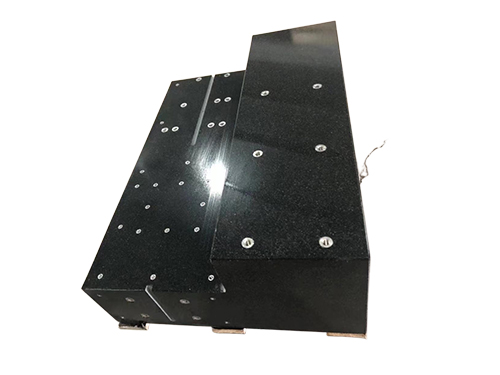

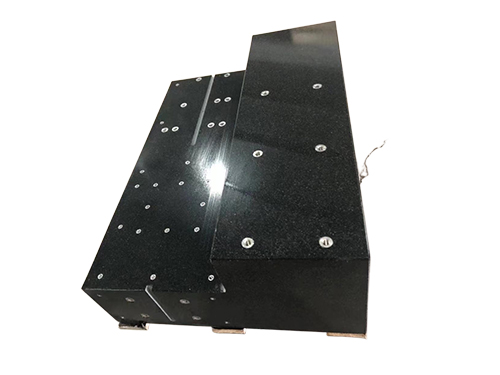

Product Details

Marble mechanical components

Marble mechanical components are granite components,and granite mechanical components are measuring tools mainly used to inspect the unevenness and straightness in machine tools.However,improper use can directly affect the accuracy of granite mechanical components and shorten their service life.Therefore,the following four points should be paid attention to during use

1、Do not stack it together with other tools:During use,use the marble bed frame components to avoid damage,and be careful not to place them on the machine tool to avoid damage caused by the vibration of the measuring tool falling off.

2、Stable measurement of parts:When using marble bed components to measure parts on a machine tool,it is necessary to protect all parts from stopping before measuring,otherwise the measuring surface of the components will wear out prematurely and lose accuracy.

3、Avoid the presence of foreign objects:Before measurement,the measuring surface of the marble bed frame components and the measured surface of the parts should be wiped clean to avoid the presence of foreign objects affecting measurement accuracy.

4、Maintain consistency between measurement and the temperature of the measured object:The measurement results are greatly affected by temperature and can generally be measured at room temperature.However,it is necessary to ensure that the temperature of the workpiece and the component are consistent.Otherwise,due to the thermal expansion and contraction characteristics of metal materials,the measurement results may be inaccurate.

Advantages of Marble Bed Components

1.Good accuracy,stability,and resistance to deformation.Can protect measurement accuracy at room temperature.

2.Non rusting,based on actual reports,no need for special maintenance,strong and long service life.

3.Scratches and bumps on the work surface do not affect measurement accuracy.

4.During measurement,it can slide smoothly without any discomfort.

5.The characteristics of the marble bed frame components are abrasion resistance,based on actual reports and maintenance.Physically stable,meticulous,with grain detachment upon impact,no burrs on the surface,and no impact on its flatness accuracy.Granite can be accurately measured on a flat plate.After long-term natural growth and aging,the structure of the rock is uniform,the coefficient of linear expansion is small,and all internal stresses disappear without deformation.

The working surface of the marble bed frame component is easy to maintain during use,with stable material that can protect it from long-term deformation.It has a small coefficient of linear expansion,good mechanical accuracy,rust prevention,anti magnetism,and insulation.No deformation,good hardness,powerful.

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province