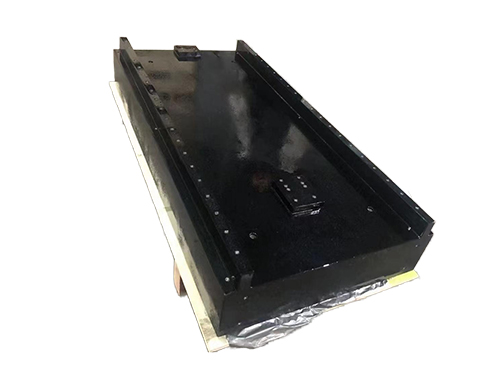

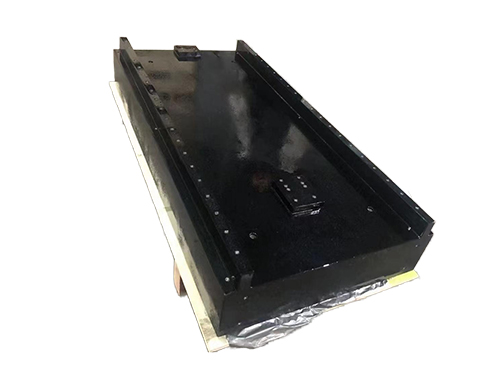

Product Details

Marble shaped components

Marble shaped components are made of"Jinan green"stone material through mechanical processing and manual precision grinding.Black luster,fine structure,uniform texture,good stability,high strength,good hardness,able to maintain suitable accuracy under heavy load and general temperature,and has the advantages of no rust,no magnetization,and no deformation.

Marble shaped components are suitable for the working environment on site and have the characteristic of maintaining the accuracy of the product itself for a long time,which can determine the accuracy of processing and testing in the working environment and the quality of the working product.

Advantages of Marble Shaped Components

1.Good precision,good stability,and not easily deformed.Can protect measurement accuracy at room temperature.

2.No rust,based on actual reports,no need for special maintenance,strong and long service life.

3.Scratches and bumps on the work surface that do not affect measurement accuracy,

4.During measurement,it can slide smoothly without any discomfort.

5.The characteristics of marble irregular components are abrasion resistance,mainly based on actual reports and maintenance.Physically stable,well-organized,grain shedding upon impact,no burrs on the surface,and no impact on its flatness accuracy.Granite is finely measured on a flat plate.Rocks undergo long-term natural growth and aging,with uniform organizational structure,low coefficient of linear expansion,complete disappearance of internal stress,and no deformation.

The working surface of marble shaped components is easy to maintain during use,with stable materials that can protect them from deformation for a long time.It has a small coefficient of linear expansion,good mechanical accuracy,rust prevention,demagnetization,and insulation.No deformation,good hardness.

Marble shaped components can also be used as mechanical test benches:suitable for various inspection work,as a reference plane for precision measurement,used as a benchmark for machine tool mechanical inspection and measurement,to check the dimensional accuracy or behavioral deviation of parts.It is an honest merchant in the mechanical industry and can also be made into mechanical accessories for high-precision instrument testing.

The process of repairing irregular marble components is divided into five steps:

Good sales:Roughly grind the marble mechanical components that need to be repaired,with the intention of achieving the most basic flatness requirements on the surface of the marble mechanical components through rough grinding.

Excellent:After rough grinding,the marble mechanical components are subjected to secondary semi fine grinding,with the intention of removing deeper scratches to achieve standard flatness.

Thirdly,the purpose of finely grinding the surface of marble mechanical components is to further refine the flatness of the semi finely ground surface.

Fourthly,manually grind the marble mechanical components with precision.The purpose of precision grinding is to further refine the precision of the marble mechanical components with precision until the required precision is achieved.

Fifth,polish the marble mechanical components that have been finely ground to meet the standard accuracy.The polished surface of the marble mechanical components is smooth and powerful,with a small plane roughness value,confirming that the accuracy is stable and the marble mechanical components are completed.The entire maintenance process requires processing,research,and repair in a constant temperature chamber.Moreover,the marble mechanical components with high precision requirements will need to be placed in a constant temperature chamber for 5-7 days.Once the precision does not rebound or change,the marble mechanical components will be considered repaired!

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province