Product Details

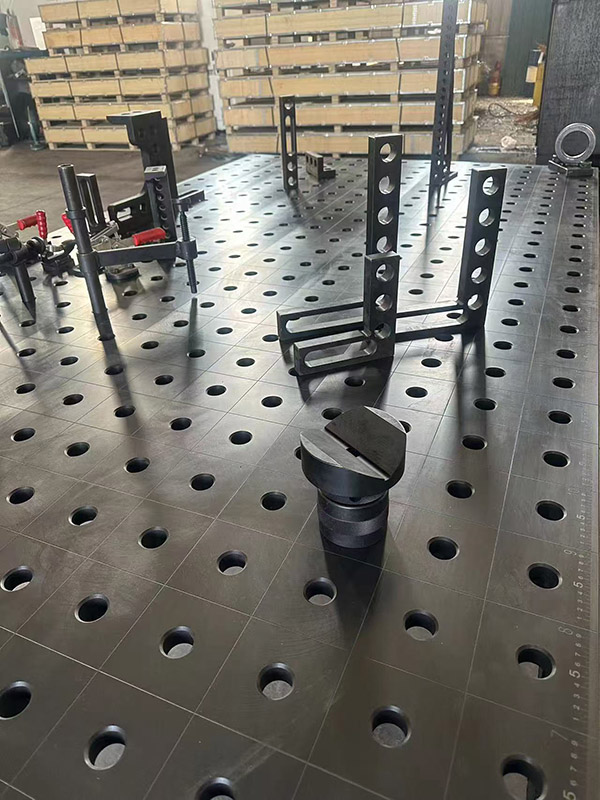

3d Flexible Welding Platform

|  |  |

|  |  |

|  |  |

The 3d Flexible Welding Platform is a set of standardized,systematic and universal tooling.It is based on the five working faces of the standardized grid holes and the workbench of the front grid line.It is equipped with various standard modules for positioning.Through the connection of pins and bolts,it can position and clamp the workpieces of various shapes.At the same time,it can also realize the random combination and repeated use of the three-dimensional space,which is suitable for the welding of a variety of workpieces and the assembly of products.

Tooling efficiency

It has strong versatility and is suitable for different workpieces.It saves the time for the design and manufacture of the construction platform before the commencement of the project,and can enter the production of the project quickly.

Flexibility

The five pin holes of the welding workbench are uniformly distributed with rules,which is suitable for the positioning of workpieces with various types and spatial dimensions,and improves the assembly efficiency and accuracy.The modular design realizes the universality of the product in the project team.

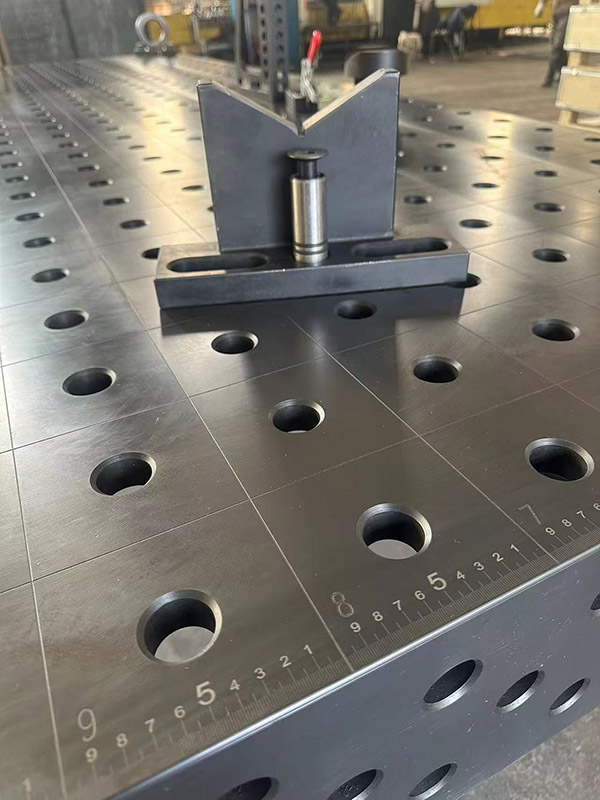

The scale on the table and the design of module size enable the operator to combine the required tooling according to the size of the workpiece.

High accuracy

The worktable is evenly distributed with scale grid lines,and the center tolerance of the positioning hole is within 0.05mm,so as to provide a reference for positioning or fixing.

The positioning block,clamp,support block,etc.are used to position and clamp the grouped workpieces to provide dimensional accuracy for subsequent welding or assembly.

Repeatability

The traditional tooling platform does not have the value of reuse for projects.The three-dimensional flexible platform can be flexibly used for different projects through the combination of platforms and standard fixture accessories.

Economy

It is reusable and versatile.

Three dimensional flexible modular fixture can save a lot of tooling manufacturing and storage,and save high cost investment.

The flexible welding platform is used for the welding process of the workpiece.Unlike the riveted welding plate,there is no hole on it,and the working surface is flat or T-shaped groove.

Applicable industries of flexible welding platform:automobile,motorcycle,engineering machinery,steel structure,industrial pipeline.

Accessories:V-shaped positioning block,plane angle ruler,positioning angle ruler,support angle iron,locking pin,L-shaped square box,etc.

Features:saving manpower and material resources

Table shape:combination of hole and grid rules

Hole system diameter:D28 and D16(hole spacing 100mm and 50mm)

Hole spacing error:the hole center distance of two adjacent holes ofφ28 is 100±0.05mm;The distance between two adjacent holes ofφ16 is 50±0.05mm

Welding platform material:cast iron ht200-300 the hardness of the working face is hb170-240.After two manual treatments(artificial annealing of 600 degrees to 700 degrees and natural aging of 2-3 years),the accuracy of the product is stable and good.

Precision of welded flat plate:it shall be implemented according to the relevant standard metrological verification regulations,which are 0,1,2 and 3 grades respectively.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province