Product Details

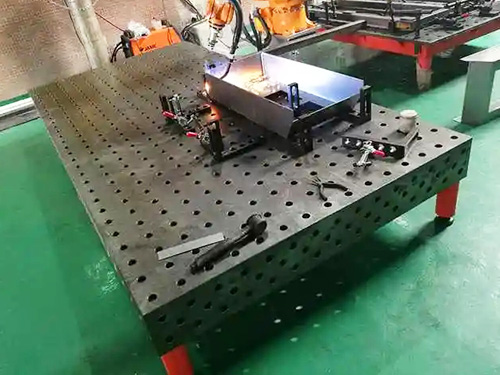

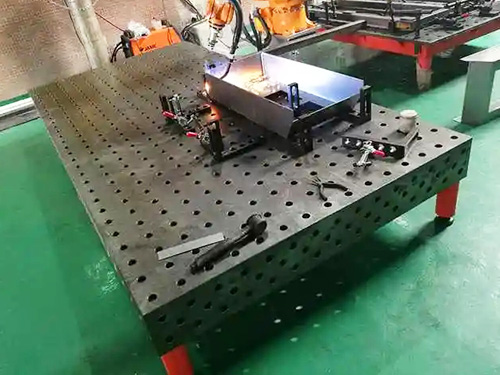

3D Welding Equipment

The 3D welding platform is a commonly used basic fixture in 3D welding equipment.The following is a detailed introduction for you:

Structure Design

Multi sided availability:3D welding platforms typically have multiple working surfaces,typically consisting of a larger plane and four side surfaces.This design breaks through the limitations of traditional welding platforms with a single working face,allowing welding operations to be performed in multiple directions and angles,providing more possibilities for complex 3D welding tasks.

Hole distribution:A series of circular holes or T-shaped grooves are evenly distributed on each working surface of the platform.The size and spacing of these holes follow certain standards,with common circular hole diameters of 28mm,16mm,etc.,and hole spacing generally being 100mm or 50mm.By installing positioning pins,fixtures,and other components in these holes,it is convenient and accurate to locate and clamp the welded workpiece,ensuring the positional accuracy of the workpiece during the welding process.

Material characteristics

Cast iron material:Commonly used cast iron materials such as HT200-300 have good wear resistance,shock absorption,and stability.After high-temperature annealing and natural aging treatment processes,the internal stress of the cast iron platform is fully eliminated,and it can maintain high precision for a long time without deformation,making it suitable for welding operations with high precision requirements.

Cast steel material:The three-dimensional welding platform made of cast steel material has higher strength,better toughness,and can withstand greater loads.In some situations where high load-bearing capacity is required for the platform,such as welding of large structural components,cast steel platforms are more suitable.

accuracy class

The accuracy of 3D welding platforms is usually classified according to the national standard metrological verification regulations,including four levels:0,1,2,and 3.Level 0 accuracy is the highest,suitable for high-precision scientific research and precision machining fields;Level 1 and Level 2 precision are suitable for general precision welding and fixture manufacturing;Level 3 precision can meet some ordinary welding operations with relatively low precision requirements.

Application advantages

Flexible production:Due to the ability to quickly assemble different fixtures and positioning components on the platform,it can adapt to welding various types and specifications of workpieces,greatly improving production flexibility and efficiency,reducing the design and manufacturing cycle and cost of fixtures and jigs.

Improving welding quality:Accurate positioning and clamping devices can ensure the positional accuracy of the workpiece during the welding process,reduce welding deformation and errors,thereby improving the stability and consistency of welding quality.

Reusability:The 3D welding platform has high wear resistance and corrosion resistance.As long as maintenance and care are taken during use,it can be reused for a long time,reducing production costs.

application area

Widely used in industries such as automobile manufacturing,aerospace,shipbuilding,engineering machinery,and rail transit.In automobile manufacturing,it is used for welding body parts;In the aerospace field,it can be used for welding and assembly of aircraft structural components;In shipbuilding,it is suitable for welding operations on various ship structures.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province