Product Details

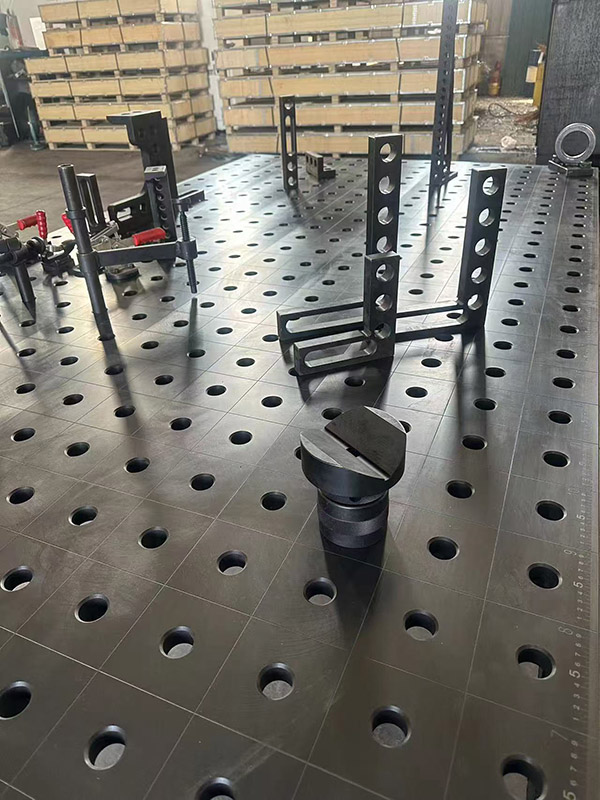

3D welding platform

|  |  |

|  |  |

|  |  |

The 3D welding platform is a welding workbench with three-dimensional design,modularization,high flexibility,high precision and reusable.The following is a detailed introduction to it:

Structural features

Various materials:mainly including casting and steel parts.The casting material,such as cast iron,has good wear resistance,shock absorption and dimensional stability;The material of steel parts has high strength,good toughness and can withstand large loads.

Multi faceted design:different from the traditional welding platform,it is expanded from one face to five faces,including a top face and four sides.This design enables the workpiece to be positioned and fixed in multiple directions,which facilitates the welding operation at different angles and positions.

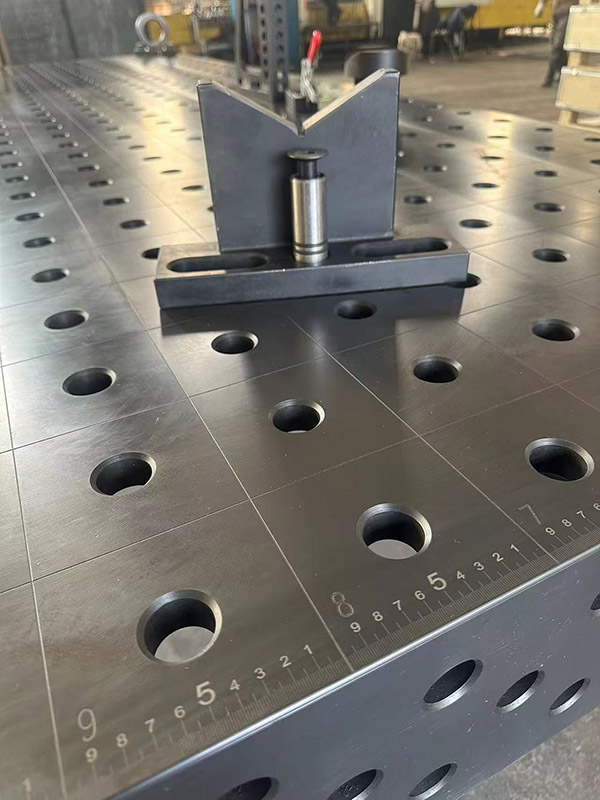

Modular design:all components are classified,standardized and serialized,and can match each other.Users can select a small number of modules according to their needs to quickly realize various positioning and clamping functions.

Uniform hole layout:circular holes with diameter of 16mm or 28mm are evenly distributed on the platform surface,and the spacing between holes is usually 25mm,50mm or 100mm.These round holes are used to install various fixtures and positioning devices,and the hole spacing tolerance of any hole can be controlled within±0.05mm,ensuring the high accuracy of positioning.

application area

Automobile manufacturing:in the welding production of automobile body,it can quickly splice the fixture suitable for different vehicle body parts,realize the high-precision positioning and welding of body parts,and improve the production efficiency and welding quality.

Construction machinery:used for welding parts of construction machinery,such as the bucket arm of excavator,the bucket of loader and other large structural parts,which can meet the welding requirements of workpieces with complex shapes and sizes.

Robot field:it is used in conjunction with the robot welding system to provide the robot with accurate workpiece positioning and fixed platform,so that the robot can complete the welding task more accurately,and improve the degree of automation and quality stability of welding.

Shipbuilding:it plays an important role in the welding of ship hull structure and the manufacturing of ship parts.It can be used to splice and fix various shapes of hull plates and skeletons to ensure the welding accuracy and the stability of ship structure.

Rail transit:it is applicable to the car body welding and bogie welding of rail transit vehicles,and can meet the high requirements of the rail transit industry for the welding accuracy and quality of parts.

advantage

Improve production efficiency:users can quickly assemble the required tooling fixtures according to the shape and size of the workpiece,without a lot of tooling design and manufacturing work like the traditional way,which greatly shortens the production preparation time and improves the production efficiency.

Improve the welding quality:the high-precision positioning hole and flexible positioning clamping mode can ensure the position accuracy of the workpiece in the welding process,reduce the welding deformation and error,so as to improve the welding quality.

Cost reduction:the modular design makes the components of the platform reusable,reducing the purchase and manufacturing costs of tooling and fixtures.At the same time,due to the improvement of production efficiency and welding quality,it also indirectly reduces the production cost.

Adapt to diversified needs:according to different workpiece and welding process requirements,the form and structure of tooling and fixtures can be flexibly combined and adjusted to meet diversified production needs.

Use and maintenance

Correct installation:during installation,the outriggers shall be installed evenly and adjusted horizontally to prevent deformation of the platform and ensure its stability and accuracy.

Handle with care:when placing the workpiece on the platform,it should be handled with care to prevent the platform surface from being impacted and to avoid surface damage and accuracy reduction.

Avoid hammering:try not to hammer on the platform surface to avoid damaging the flatness and accuracy of the platform.

Keep clean:after use,iron filings,welding slag and other sundries on the platform surface shall be cleaned in time to avoid scratching and wearing the platform surface.When it is not used for a long time,it needs to be coated with anti rust oil to prevent rust.

Uniform use:in the process of use,it is necessary to ensure the uniform use of the platform everywhere to avoid uneven wear caused by local overuse,which will affect the accuracy and service life of the platform.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province