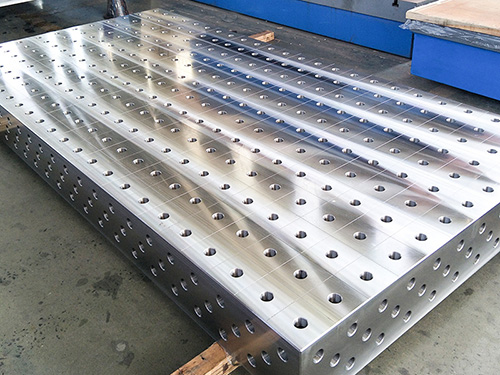

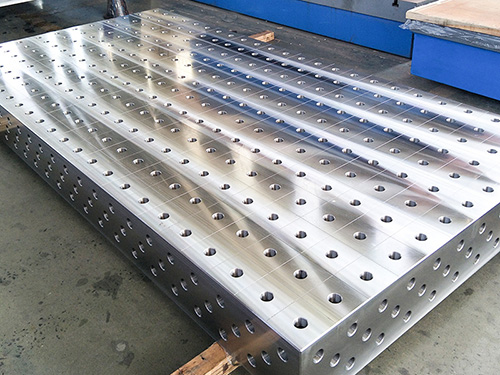

Product Details

3D welding table clamping device fixture tool

There are various types of 3D welding table clamping device fixture tools, and the following are some common types and usage methods:

Quick Clamp

Type: There are various styles, such as bow shaped clamps, C-shaped clamps, etc.

Features: Easy to operate, able to quickly clamp and release workpieces, improving work efficiency.

Usage: Align the jaws of the clamp with the part that needs to be clamped, and manually operate the lever or wrench to tightly clamp the workpiece with the jaws. When releasing, simply reverse the operation.

Positioning pin fixture

Type: including positioning pins of different shapes such as cylindrical pins and conical pins.

Features: High positioning accuracy, ensuring accurate positioning of the workpiece during the welding process.

Usage: First, install the positioning pin at a specific position on the welding table, and then match the corresponding positioning hole on the workpiece with the positioning pin to accurately position the workpiece on the welding table. Usually, it needs to be used in conjunction with other clamping devices to ensure that the workpiece does not move during welding.

Magnetic fixture

Types: There are permanent magnet fixtures and electromagnetic fixtures.

Features: Using magnetic clamping to clamp workpieces, suitable for some magnetic material workpieces that do not require particularly high clamping force but require quick loading and unloading.

Usage: Place the magnetic fixture in a suitable position on the welding table, and then place the workpiece within the magnetic range of the fixture. The fixture will automatically attach the workpiece to achieve clamping. For electromagnetic fixtures, it is necessary to connect the power supply to generate magnetic force. After use, turn off the power supply to release the workpiece; The permanent magnet fixture controls the presence or absence of magnetic force by manually operating the magnetic switch.

pneumatic fixture

Type: Composed of components such as cylinders and air claws.

Features: Stable clamping force, can control the clamping force by adjusting the air pressure, and has a high degree of automation, suitable for mass production.

Usage: First, connect the pneumatic fixture to the compressed air source, and control the pneumatic valve to make the cylinder move, driving the air claw to open or close, thereby achieving clamping and releasing of the workpiece. Before use, it is necessary to adjust the air pressure and fixture stroke according to factors such as the material, shape, and size of the workpiece.

assembling clamp

Type: Composed of various types of fixture components, it can be flexibly assembled according to specific welding tasks.

Features: Strong universality, able to adapt to various shapes and sizes of workpieces, reducing the inventory cost of fixtures.

Usage: Based on the shape of the workpiece and welding requirements, select appropriate fixture components such as positioning blocks, clamping blocks, bolts, nuts, etc., and then assemble these components into a complete fixture system for fixing the workpiece. During the assembly process, attention should be paid to the installation position and connection method of each component to ensure the stability and reliability of the fixture.

When using these 3D welding table clamping device fixture tools, it is necessary to select the appropriate fixture type and specifications according to the material, shape, size, and welding process requirements of the workpiece, and correctly install and operate the fixture to ensure that the workpiece can maintain a stable position and posture during the welding process, and ensure the welding quality. At the same time, it is necessary to regularly inspect and maintain the fixtures, and replace worn or damaged parts in a timely manner to extend the service life of the fixtures.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province