Product Details

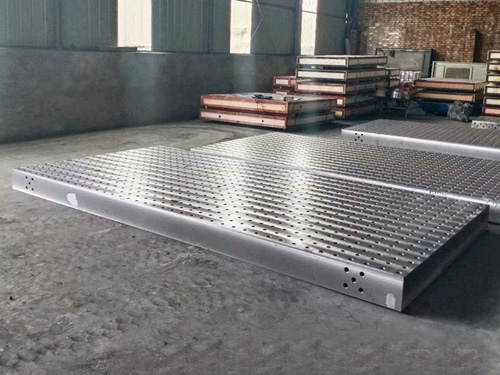

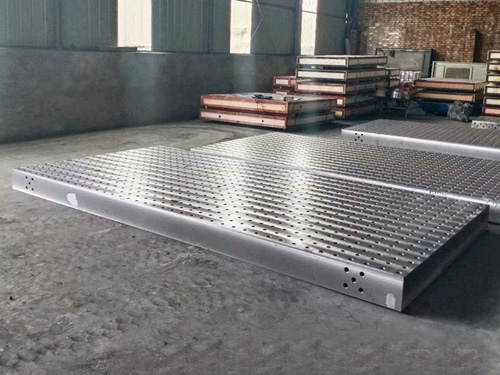

Aviation Technology Welding Tool Platform

An aviation technology welding tool platform is a specialized and high-precision equipment designed for the unique requirements of the aviation industry.Here's an in-depth look at its key aspects:

1.Structure and Design

High-strength and Lightweight Materials:Given the strict weight requirements in aviation,the platform is typically constructed from materials like high-strength aluminum alloys or titanium alloys.These materials offer excellent strength-to-weight ratios,ensuring the platform can withstand the rigors of welding operations while remaining relatively lightweight.For example,titanium alloys are highly resistant to corrosion and can maintain their mechanical properties even at elevated temperatures,which is crucial in aviation environments.

Precision Machining:The components of the platform are manufactured with extremely high precision.The tabletop,for instance,is often machined to very fine tolerances to provide a flat and stable surface for welding.This precision is essential for ensuring accurate positioning of aircraft components during the welding process,as even minor inaccuracies can have significant consequences for the structural integrity of the aircraft.

Modular and Flexible Design:To accommodate a wide range of aviation welding tasks,the platform usually features a modular design.Different modules can be added or removed as needed,such as specialized clamping fixtures,tool storage units,and adjustable height mechanisms.This flexibility allows the platform to be customized for specific welding applications,whether it's working on small engine components or large fuselage sections.

2.Features

Advanced Clamping and Positioning Systems:The platform is equipped with sophisticated clamping and positioning devices.These systems use a combination of mechanical,hydraulic,or pneumatic mechanisms to securely hold aircraft components in place during welding.For example,magnetic clamping systems can provide a strong and precise hold without causing damage to the surface of the components.Additionally,some platforms may incorporate laser-based positioning systems to ensure that the components are accurately aligned before welding.

Integrated Dust and Fume Extraction:Welding in the aviation industry often involves materials that produce harmful fumes and dust.To protect the health of workers and maintain a clean working environment,the platform is integrated with a high-performance dust and fume extraction system.This system can quickly and effectively remove welding fumes and particles,ensuring compliance with strict safety and environmental regulations.

Temperature and Stress Monitoring:Since aviation components are subject to extreme conditions during flight,it's crucial to monitor the temperature and stress levels during the welding process.The platform may be equipped with sensors that can continuously monitor these parameters and provide real-time feedback to the welder.This allows for immediate adjustments to be made to the welding process to prevent issues such as thermal distortion or excessive stress concentrations.

.Applications

Aircraft Component Manufacturing:The platform is used extensively in the manufacturing of various aircraft components,including wings,fuselages,engines,and landing gear.It enables precise welding of complex structures,ensuring the structural integrity and performance of the aircraft.For example,in the fabrication of wing spars,the platform's high-precision positioning and clamping systems are essential for achieving accurate welds that can withstand the aerodynamic forces during flight.

Maintenance and Repair:In addition to new manufacturing,the platform plays a vital role in aircraft maintenance and repair.When repairing damaged components,the platform provides a stable and accurate working surface for welding operations.It allows for the precise alignment and welding of replacement parts,ensuring that the repaired components meet the same high standards as the original ones.

Research and Development:In aviation research and development,the platform is used to test new welding techniques and materials.Its advanced features and flexibility make it an ideal tool for exploring innovative approaches to aircraft manufacturing and repair,helping to drive the development of new technologies in the aviation industry.

4.Importance

Ensuring Safety:By providing a stable and accurate platform for welding,it helps to ensure the structural integrity of aircraft components,which is directly related to the safety of passengers and crew.Precise welding reduces the risk of component failure during flight,contributing to the overall safety of the aircraft.

Meeting Quality Standards:The aviation industry has extremely high quality standards,and the platform's precision and advanced features enable manufacturers and repairers to meet these standards consistently.It ensures that all welding operations are carried out with the highest level of quality,resulting in reliable and durable aircraft components.

Enhancing Efficiency:The platform's modular and flexible design,along with its advanced features,helps to streamline the welding process.It reduces setup times,improves productivity,and allows for more efficient use of resources,ultimately contributing to the overall efficiency of aircraft manufacturing and maintenance operations.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province